Flexible fabric-based strain sensor and preparation method thereof

A strain sensor and flexible fabric technology, applied in the sensor field, can solve the problems of small sensing range, low sensitivity, wide strain, poor bonding force of conductive material elastic fabric, etc., to achieve the effect of enhancing adhesion and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

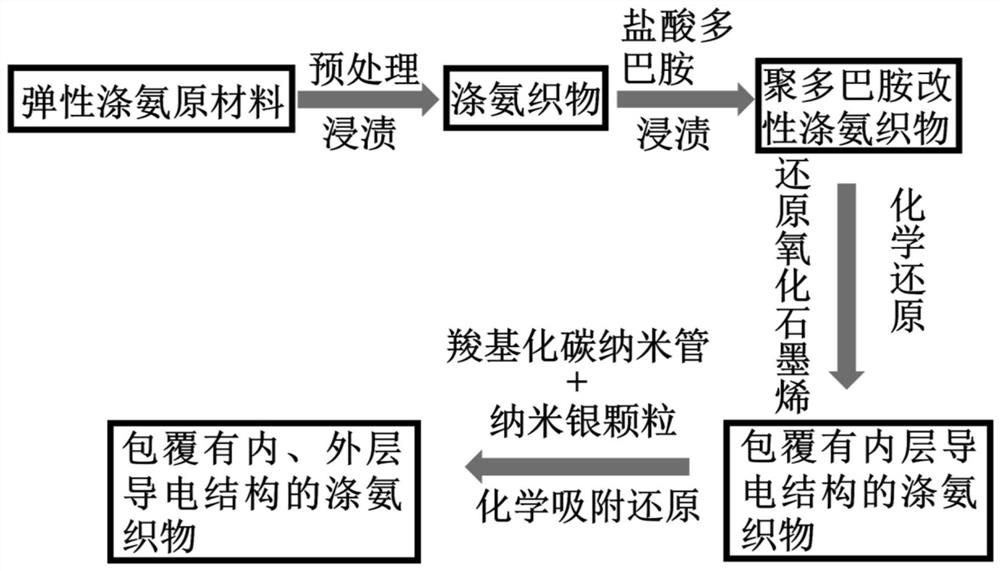

[0066] A method for fabricating flexible fabric-based strain sensors, such as figure 2 , including the following steps:

[0067] (1) Dip the polyester ammonia fabric in a solution containing sodium hydroxide (2g / L), take it out after dipping at a constant temperature of 85°C for 45 minutes, wash, dry and weigh for subsequent use; obtain the pretreated polyester ammonia fabric;

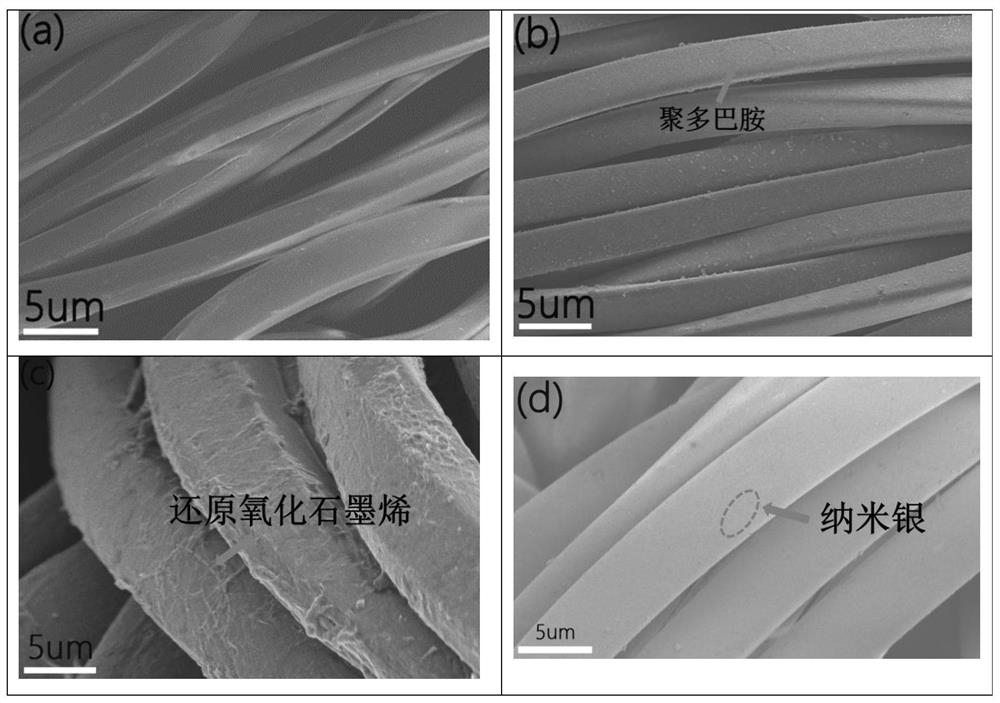

[0068] (2) Immerse the pretreated polyester ammonia fabric obtained in step (1) in a mixed solution containing dopamine hydrochloride (2 mg / mL) and tris buffer (1 M), the pH of the solution is 8.5; then at room temperature (25° C. ) under magnetic stirring (80rpm) for 24h; washing and drying to obtain a polydopamine-modified polyester / ammonia fabric;

[0069] (3) Immerse the polydopamine-modified polyester / ammonia fabric obtained in step (2) in graphene oxide dispersion (30 mM), the immersion temperature is 65°C, the immersion time is 30min, and then dried at 60°C for 30min; then the drying The resu...

Embodiment 2

[0087] A method for preparing a flexible fabric-based strain sensor, comprising the steps of:

[0088] (1) dipping the bromine fabric in a solution containing sodium hydroxide (2g / L), taking out after dipping at a constant temperature of 45min at 85°C, washing, drying, and weighing for subsequent use; obtain the pretreated bromine fabric;

[0089] (2) Immerse the pretreated bromine fabric obtained in step (1) in a mixed solution containing dopamine hydrochloride (2 mg / mL) and tris buffer (1 M), the pH of the solution is 8.5; then at room temperature (25° C. ) under magnetic stirring (80rpm) for 24h; washing and drying to obtain polydopamine-modified bromine fabric;

[0090] (3) immersing the polydopamine-modified nylon fabric obtained in step (2) in a dispersion solution containing carboxylated carbon nanotubes (30 mM) at room temperature for 30 minutes, and then drying at 60° C. for 30 minutes; obtaining an inner layer coated with Nylon fabric with conductive structure (carb...

Embodiment 3

[0097] Adjust the concentration of graphene oxide dispersion in Example 1 to be 10, 20, and 40 mM, omit step (4), and other are consistent with Example 1 to obtain a polyester ammonia fabric coated with reduced graphene oxide nanosheets.

[0098] The polyester ammonia fabric coated with reduced graphene oxide nanosheets will be obtained and tested for performance, and the test results are as follows:

[0099] The test result of table 5 embodiment 3

[0100]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com