Unfired foamed ceramic partition wall board and preparation method thereof

A technology for foaming ceramics and partition boards, which is applied in the field of building materials, can solve the problems of poor structural strength, high energy consumption, and no sintering, and achieve the effects of low manufacturing cost, high process energy consumption, and good structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

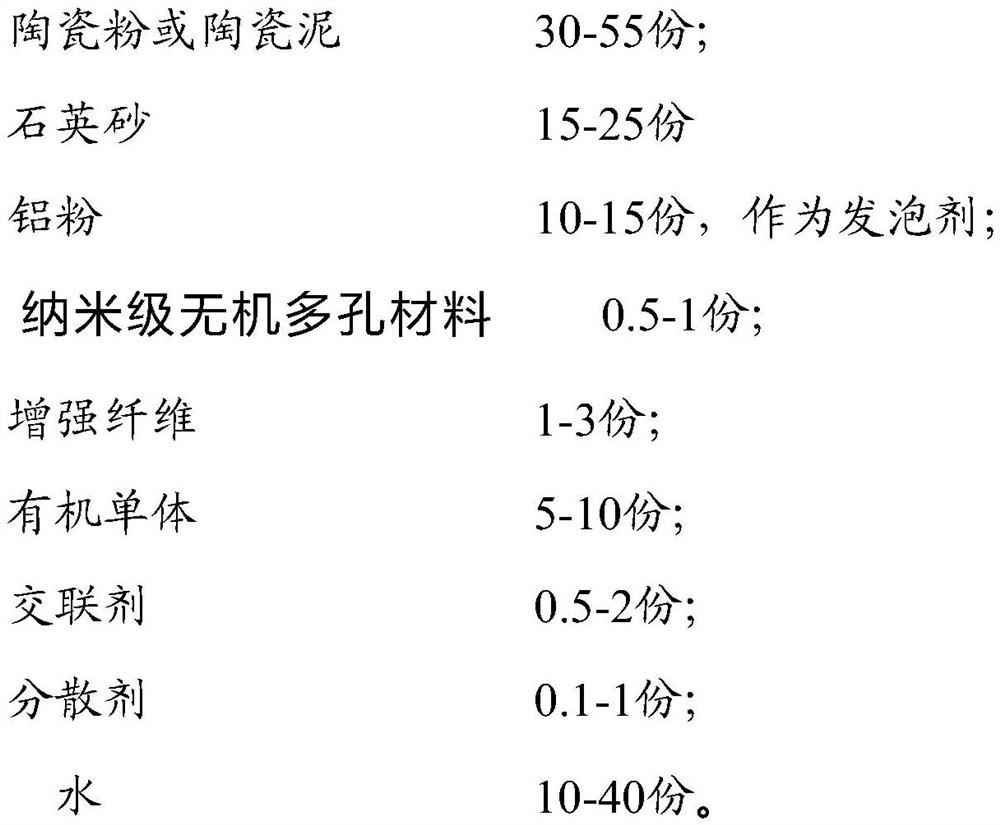

[0026] Embodiment 1: A non-fired foamed ceramic partition board, comprising a foamed ceramic partition board base formed by a foaming process, the foamed ceramic partition board base includes the following raw materials in parts by weight:

[0027]

[0028]

[0029] Preferably, in order to facilitate the hydrophobicity and durability of the non-fired foamed ceramic partition wall panels, in this embodiment, the surface of the foamed ceramic partition wall panels is subjected to penetration-enhancing coating treatment with a surface enhancer, which is used for A layer of hydrophobic protective film is formed on the surface of the base body of the foamed ceramic partition board; specifically, preferably, the surface enhancer is an organic silicon penetrating waterproofing agent, and the organic silicon penetrating waterproofing agent is coated on the surface of the base body of the foaming ceramic partition board and generates carbon dioxide. From the polymerization reactio...

Embodiment 2

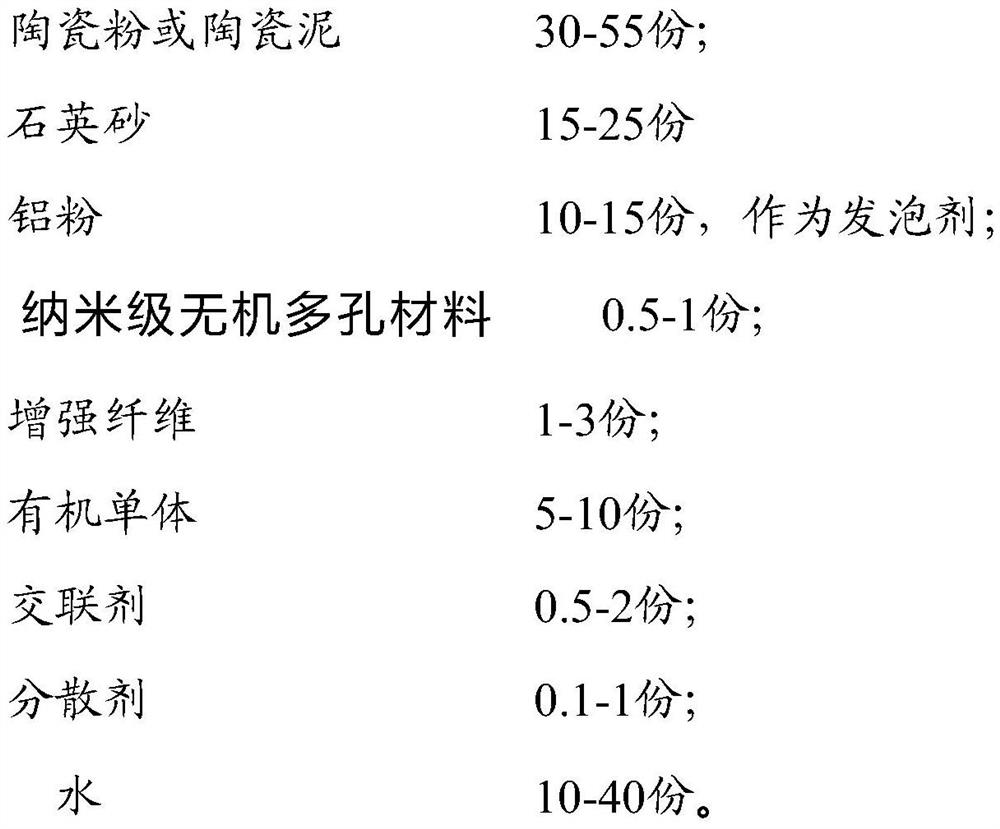

[0037] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1. The difference is that this embodiment 2 proposes a non-fired foamed ceramic partition wall board, and its foamed ceramic partition wall board base body includes the following parts by weight raw material:

[0038]

Embodiment 3

[0039] Embodiment 3: The remaining technical solutions of this embodiment 3 are the same as those of embodiment 1. The difference is that this embodiment 3 proposes a non-fired foamed ceramic partition board, and its foamed ceramic partition board base body includes the following parts by weight raw material:

[0040]

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com