Turning anti-splashing machine tool

A machine tool and turning technology, which is applied to the components of boring machines/drilling machines, metal processing machinery parts, maintenance and safety accessories, etc. Maintenance quality and machine durability, improved stability and anti-offset, improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

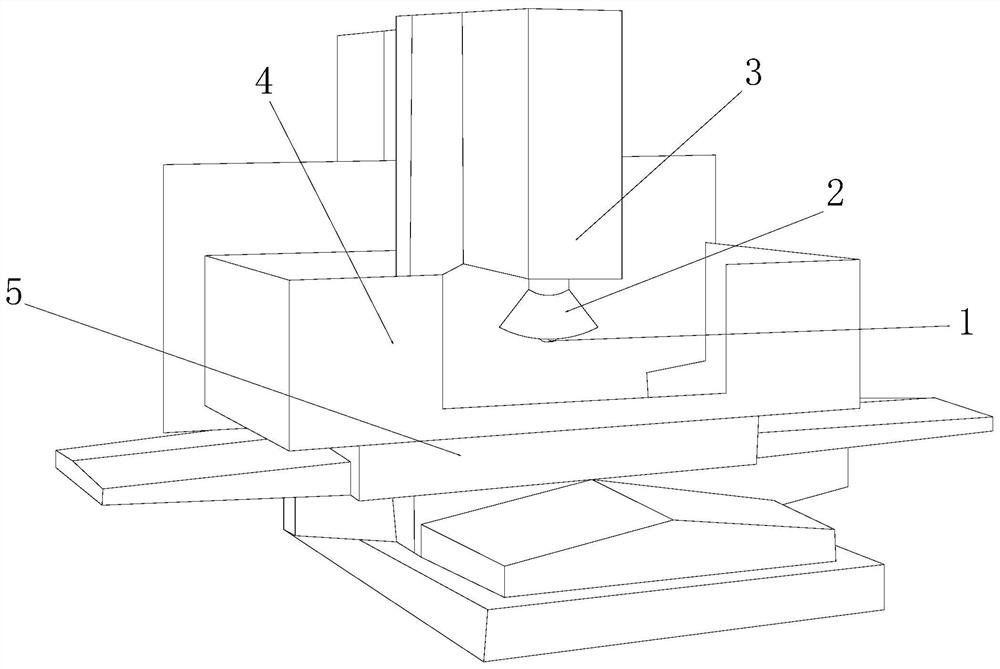

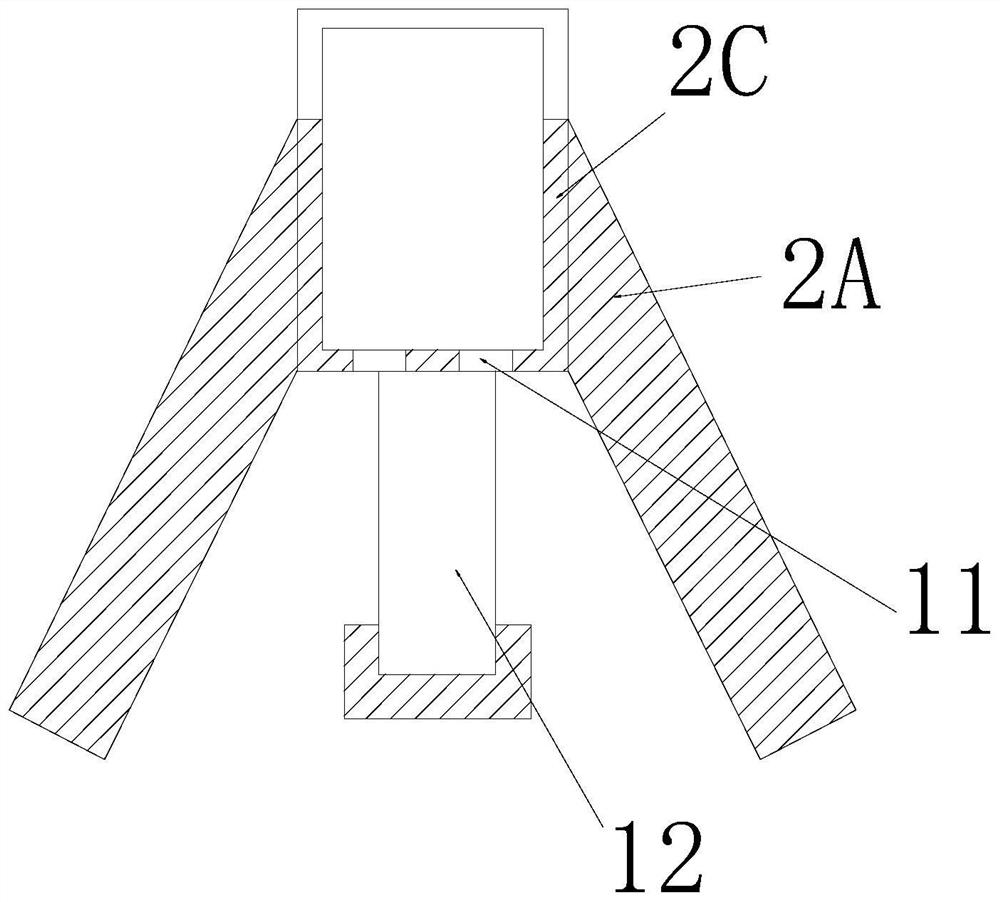

[0035] see Figure 1-Figure 8 , the present invention provides a turning anti-splash machine tool, the structure of which includes: a drill rod 1, a baffle shaft sleeve seat 2, a shaft motor barrel 3, a turning groove 4, a platform support seat 5, and the baffle shaft sleeve The seat 2 is nested under the bottom of the shaft motor barrel 3 and the axes are collinear. The drill rod 1 is inserted under the bottom of the baffle shaft sleeve seat 2 and the axes are collinear. The shaft motor barrel 3 Installed directly above the turning groove 4, the turning groove 4 is installed on the top of the platform support seat 5, the baffle shaft sleeve seat 2 is provided with a balloon baffle frame 2A, a side pad shaft sleeve 2B, shell frame barrel groove 2C, the said balloon baffle frame 2A is provided with two and respectively inserted in the left and right lower corners of the shell frame barrel groove 2C, the side pad shaft sleeve 2B is installed in the shell frame barrel groove 2C ...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a turning anti-splash machine tool, other aspects are the same as embodiment 1, the difference is:

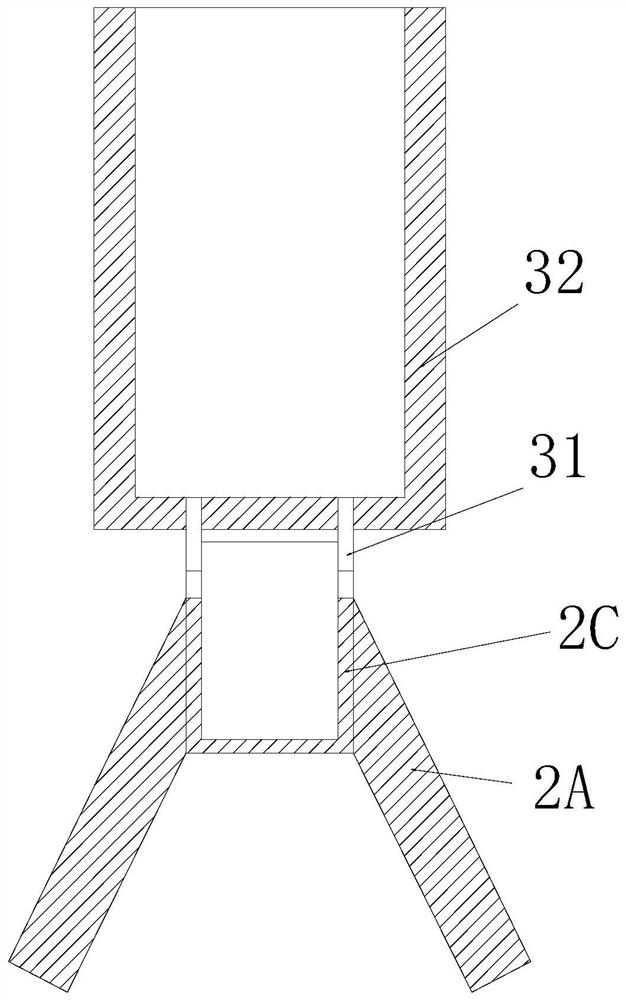

[0044] see image 3 , the shaft motor barrel 3 is composed of a beam splint 31 and a motor barrel shell 32. The beam splint 31 is installed under the bottom of the motor barrel shell 32. The beam splint 31 and the motor barrel shell 32 are inserted together and mutually Vertically, the reinforcement effect of the lock pin is improved by inserting the bundle splint 31 at the bottom of the motor casing 32 .

[0045] see Figure 6 , the splint 31 is composed of a splint body 311 and a gasket bundle barrel 312, the splint body 311 is installed inside the gasket bundle barrel 312, and the splint body 311 and the gasket bundle barrel 312 adopt an interference fit and are in On the same vertical plane, the gasket beam barrel 312 is a composite beam barrel structure with a circular gasket insertion barrel groove at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com