Sea buckthorn oil with high oxidation resistance and high stability, sea buckthorn oil powder and preparation method thereof

A high stability, seabuckthorn oil powder technology, applied in the field of seabuckthorn oil, can solve the problems of reducing product competitiveness and consumer acceptance, reducing physiological efficacy, reducing product acceptance, etc., to improve product safety and acceptability , Realize the effect of waste resource utilization and high market acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of Seabuckthorn Leaf Extract

[0041] The dried seabuckthorn leaves were crushed and mixed with water according to the ratio of 1g:8mL of solid to liquid, refluxed and extracted at 60°C for 1 hour, and extracted twice in total, the extracts were combined, and the extracts were subjected to ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 20,000. Filtration, rotary evaporation and concentration to obtain a concentrated solution, maltodextrin and cyclodextrin (amount ratio of 3g:1g) were added to the concentrated solution according to the ratio of 1g:5mL of solid to liquid, and spray-dried to obtain seabuckthorn leaf extract.

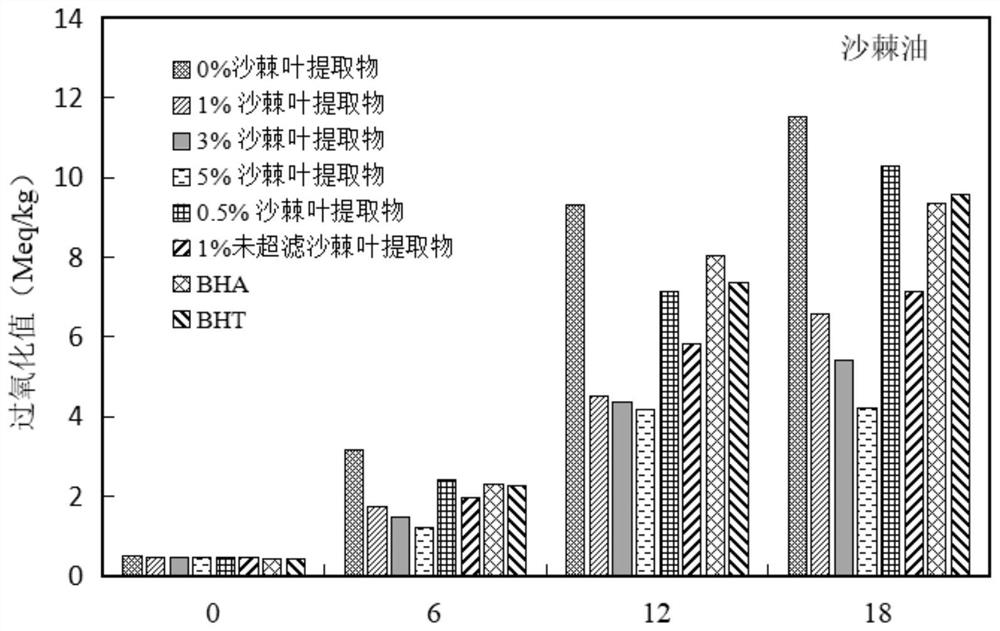

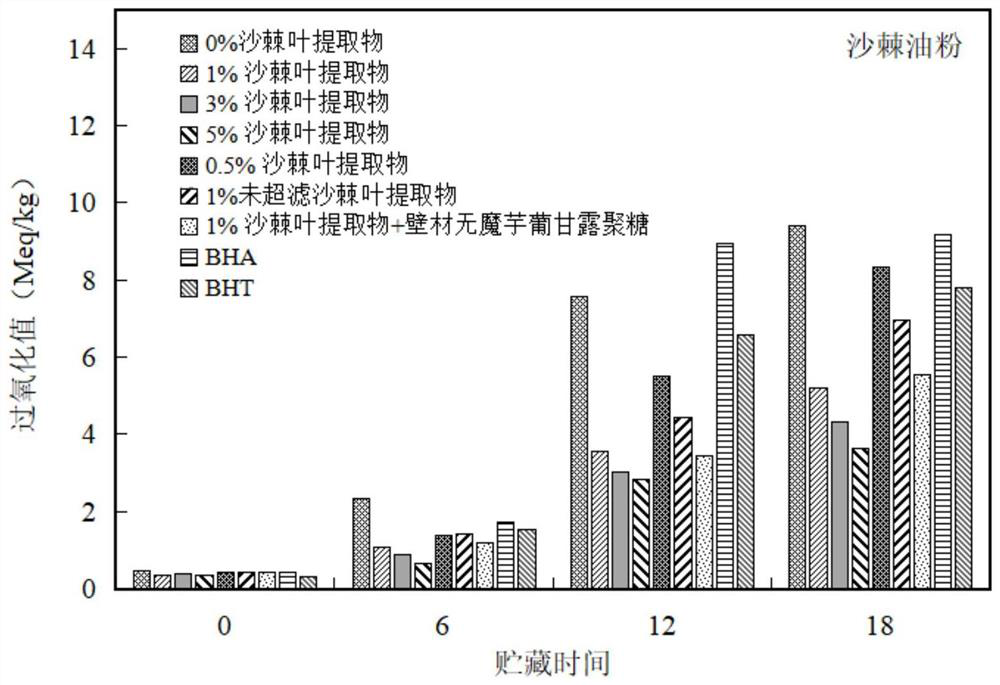

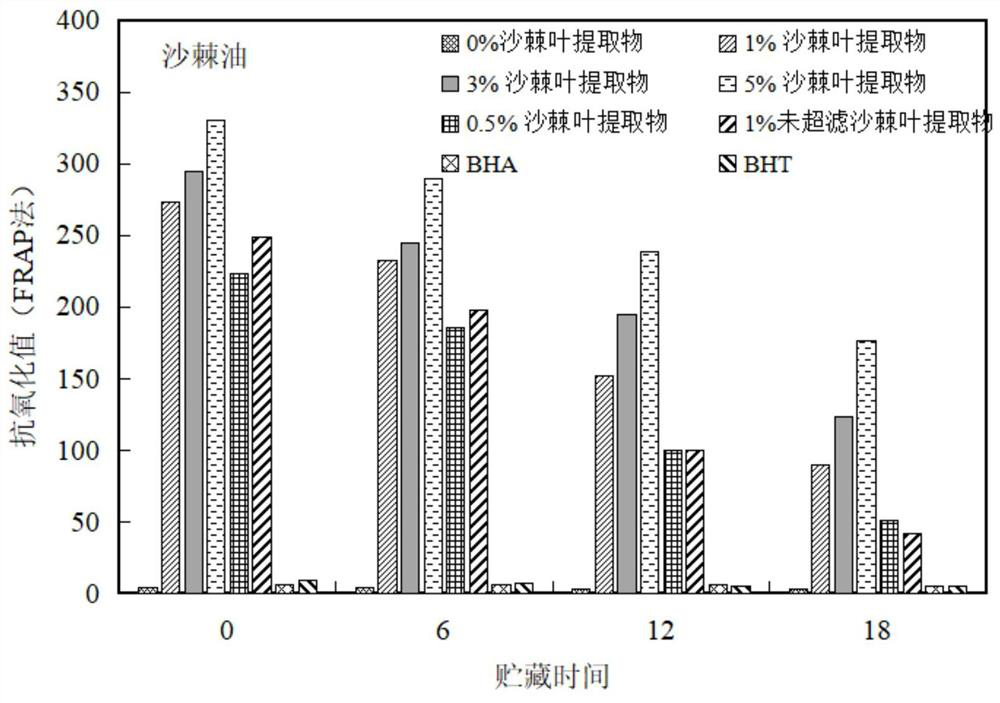

[0042] (2) Preparation of seabuckthorn oil

[0043] The seabuckthorn leaf extract and seabuckthorn seed oil are mixed according to a mass ratio of 1:100, and stirred evenly to obtain seabuckthorn oil with high stability and high antioxidant capacity.

Embodiment 2

[0045] (1) Preparation of Seabuckthorn Leaf Extract

[0046] Mix the crushed dry seabuckthorn leaves with water according to the solid-liquid ratio of 1g:7mL, reflux extraction at 70°C for 0.5h, extract once in total, combine the extracts, and filter the extracts with an ultrafiltration membrane with a molecular weight cut-off of 30,000 Ultrafiltration, rotary evaporation and concentration to obtain a concentrated solution, maltodextrin and cyclodextrin (amount ratio of 4g:1g) were added to the concentrated solution according to a solid-liquid ratio of 1g:4mL, and spray-dried to obtain sea buckthorn leaf extract.

[0047] (2) Preparation of seabuckthorn oil

[0048] The seabuckthorn leaf extract and seabuckthorn fruit oil are mixed according to the mass ratio of 3:100, and stirred evenly to obtain seabuckthorn oil with high stability and high antioxidant capacity.

Embodiment 3

[0050] (1) Preparation of Seabuckthorn Leaf Extract

[0051] The dried seabuckthorn leaves were crushed and mixed with ethanol according to the solid-liquid ratio of 1g:9mL, refluxed and extracted at 50°C for 2h, and extracted 3 times in total, the extracts were combined, and the extracts were subjected to ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 50,000. Filtrate, concentrate by rotary evaporation to obtain a concentrated solution, maltodextrin and cyclodextrin (amount ratio of 2g:1g) were added to the concentrated solution according to a solid-liquid ratio of 1g:6mL, and spray-dried to obtain seabuckthorn leaf extract.

[0052] (2) Preparation of seabuckthorn oil

[0053] The seabuckthorn leaf extract and seabuckthorn seed oil are mixed according to a mass ratio of 5:100, and stirred evenly to obtain seabuckthorn oil with high stability and high antioxidant capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com