Sponge fiber, preparation method and application

A fiber and sponge technology, applied in the field of fibers, can solve the problems of insufficiently dense structure, low degree of orientation, and single structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The present embodiment has prepared a kind of sponge fiber, and concrete process is:

[0077] S1. configure the mixed aqueous solution of phytic acid and sodium sulfate to obtain mixed aqueous solution I, wherein the concentration of phytic acid is 7.5wt%, and the concentration of sodium sulfate is 5wt%;

[0078] S2. Weigh 80g of lithium hydroxide and 150g of urea, add 770mL of ultrapure water, stir and dissolve to obtain the mixed aqueous solution II;

[0079] S3. Place 500g of the mixed aqueous solution II (solvent) and 29.1g of cotton linters (natural cellulose) at -25°C for cooling for 2h;

[0080] S4. Mix and stir the mixed aqueous solution II and cotton linters after cooling in step S3 (rotating speed 1500rad / min, time 5min) to obtain a transparent cellulose solution;

[0081] S5. centrifuging the cellulose solution obtained in step S4 to obtain a supernatant A, wherein the centrifugation speed is 8000 rad / min, the time is 30 min, and the temperature is 0° C.;

...

Embodiment 2

[0089] This embodiment has prepared a kind of sponge fiber, and the difference of concrete process and embodiment 1 is:

[0090] (1) In step S6, the addition ratio of crosslinking agent epichlorohydrin is 1.5mL crosslinking agent / 200g supernatant A;

[0091] (2) In step S8, the propulsion speed of the cooled supernatant B is 220 μL / min; the propulsion speed of the mixed aqueous solution II is 500 μL / min; the propulsion speed of the mixed aqueous solution I is 500 μL / min.

[0092] (3) In step S10, the drying method is freeze drying, and the drying time is 3 hours.

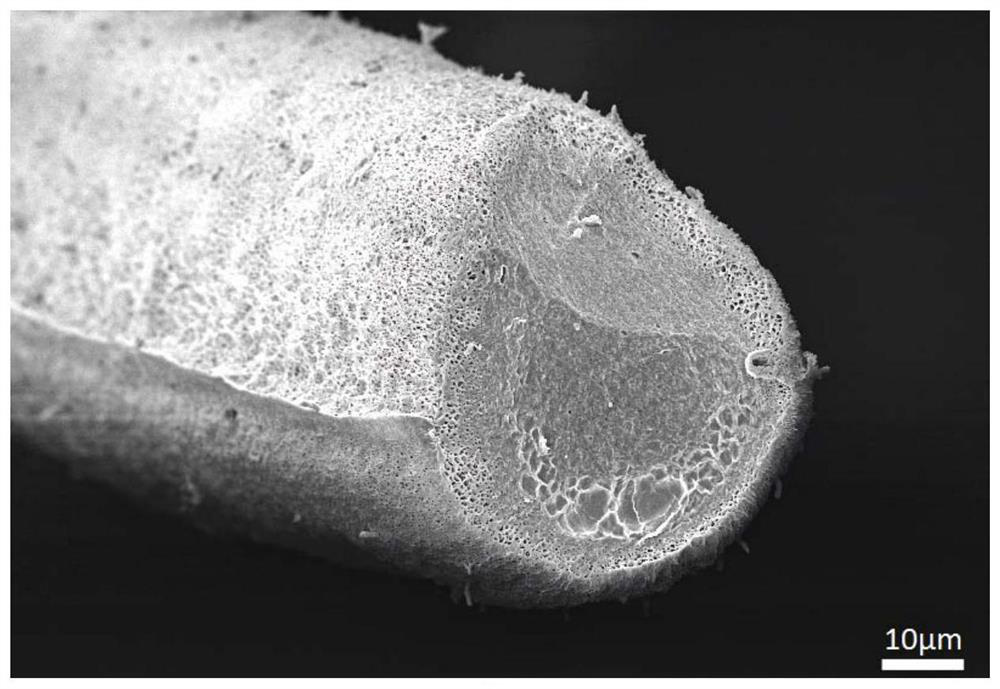

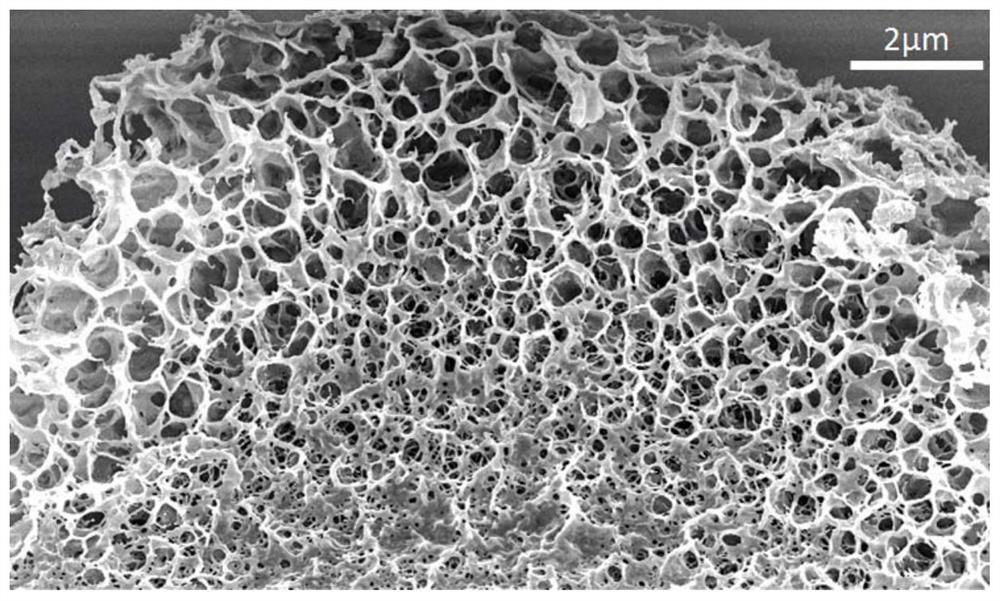

[0093] The SEM figure of the sponge fiber obtained in the present embodiment is as follows Figure 4 shown.

Embodiment 3

[0095] This embodiment has prepared a kind of sponge fiber, and the difference of concrete process and embodiment 2 is:

[0096] (1) In step S3, the quality of cotton linters is 31.9g;

[0097] (2) In step S6, the addition ratio of crosslinking agent epichlorohydrin is 3mL crosslinking agent / 200g supernatant A;

[0098] (3) In step S6, the stirring time is 2h;

[0099] (4) In step S8, the propulsion speed of the cooled supernatant B is 150 μL / min; the propulsion speed of the mixed aqueous solution II is 300 μL / min; the propulsion speed of the mixed aqueous solution I is 400 μL / min;

[0100] (5) In step S10, freeze-dry for 6 hours.

[0101] The SEM figure of the sponge fiber obtained in the present embodiment is as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com