A kind of in-situ preparation method of ni/nio composite material and its application

A composite material, in-situ preparation technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of low catalytic activity and stability of catalysts, weak interaction between carriers and metals, It is difficult to separate from the impregnating liquid, etc., to achieve the effect of ultra-high catalytic activity and selectivity, tight binding, and not easy to deactivate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

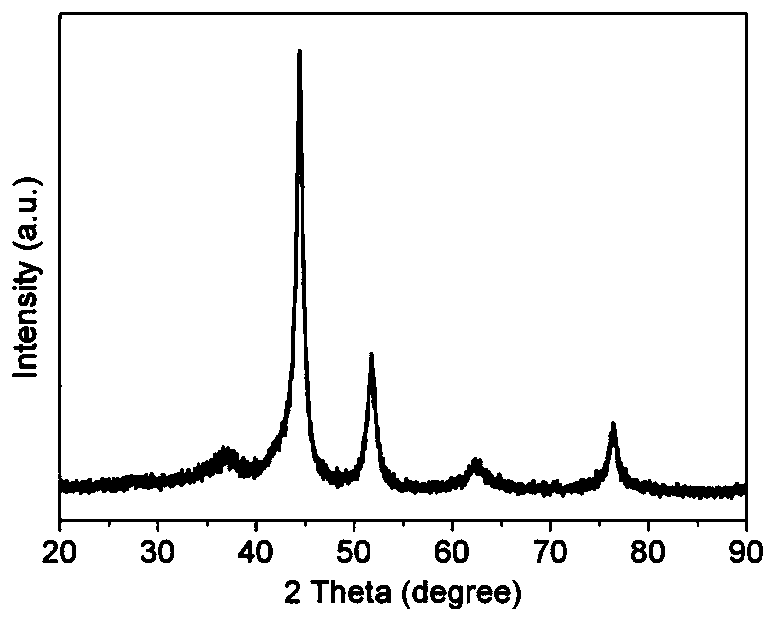

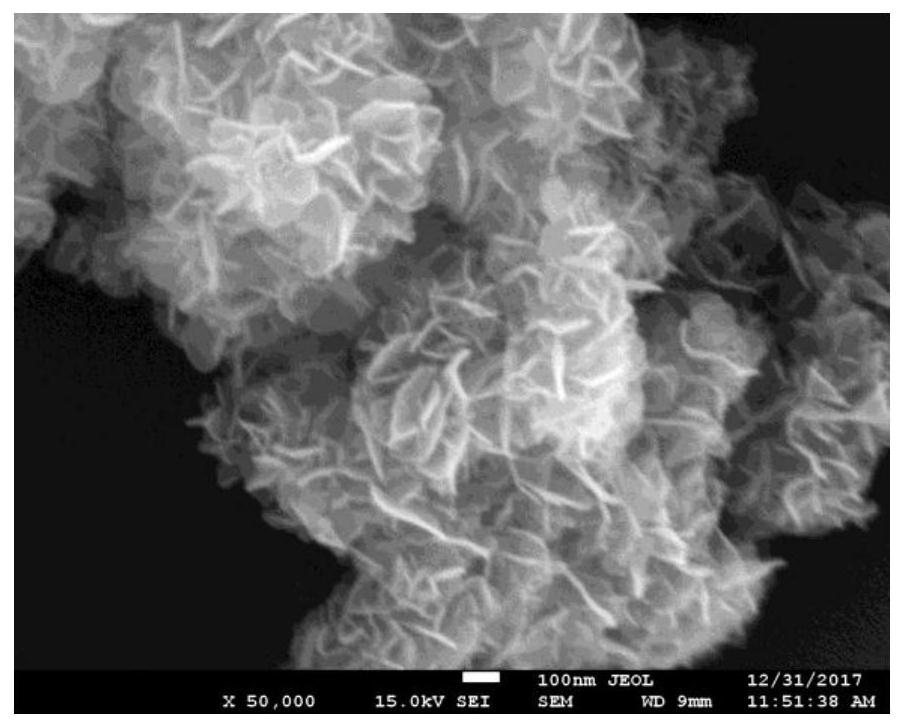

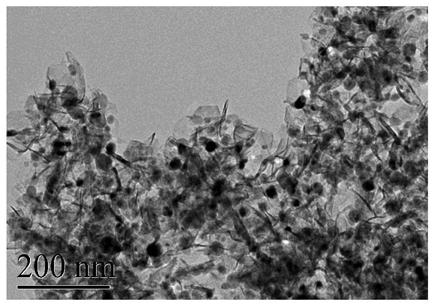

[0034] This embodiment proposes a method for preparing a Ni / NiO composite material, including the following steps:

[0035] (1) The nickel source is fully dissolved in an inorganic solvent to form a solution A;

[0036] (2) Add a strong reducing agent to the solution A to form a mixed solution;

[0037] (3) subjecting the mixed solution obtained in step (2) to a hydrothermal reaction to obtain a solid-liquid mixture, which is separated, washed, and dried to obtain the solid-liquid mixture;

[0038] (4) performing a high-temperature thermal decomposition reaction on the precursor I in step (3) to obtain the precursor II;

[0039] (5) Reducing the precursor II in step (4) under a reducing gas atmosphere to obtain a Ni / NiO composite material.

[0040] In this embodiment, the molar concentration ratio of the nickel source and the strong reducing agent is 0.1˜2.5:3. Preferably, the molar concentration ratio of the nickel source and the strong reducing agent is 1:3.

[0041] In ...

Embodiment 1

[0054] Embodiment 1 proposes a kind of in-situ preparation method of Ni / NiO composite material, comprises the following steps:

[0055] (1) Weigh 0.582g of nickel nitrate hexahydrate and add it to 40mL of deionized water, and stir at a constant speed until the nickel nitrate hexahydrate is fully dissolved to form solution A;

[0056] (2) Take again 0.226g of sodium borohydride and add it to the solution A in step (1), and stir evenly for 5min to form a mixed solution;

[0057] (3) Transfer the mixed solution to a 50mL autoclave with polytetrafluoroethylene as the inner liner, and the filling amount of the inner liner is 80%, then put the autoclave into the oven, and naturally heat up to 120°C Afterwards, heat preservation for 1 hour, and after natural cooling to room temperature, the autoclave was taken out to obtain a solid-liquid mixture;

[0058] (4) The solid-liquid mixture was washed three times successively with water and absolute ethanol, and after each washing, use a ...

Embodiment 2

[0063] Embodiment 2 proposes a kind of in-situ preparation method of Ni / NiO composite material, comprises the steps:

[0064] (1) Weigh 0.582g of nickel nitrate hexahydrate and add it to 40mL of deionized water, and stir at a constant speed until the nickel nitrate hexahydrate is fully dissolved to form solution A;

[0065] (2) Take again 0.226g of sodium borohydride and add it to the solution A in step (1), and stir evenly for 5min to form a mixed solution;

[0066] (3) Transfer the mixed solution to a 50mL autoclave with polytetrafluoroethylene as the inner liner, and the filling amount of the inner liner is 80%, then put the autoclave into the oven, and naturally heat up to 180°C After keeping it warm for 2 hours, after cooling down to room temperature naturally, the autoclave was taken out to obtain a solid-liquid mixture;

[0067] (4) The solid-liquid mixture was washed three times successively with water and absolute ethanol, and after each washing, use a centrifuge at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com