Condensation method oil gas recovery method and device

A recovery method and technology of a recovery device, which are applied in the recovery of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of increasing the operating power of the unit, reducing the service life of the adsorbent, and increasing the energy consumption of condensation, so as to improve the condensation effect and reduce the number of devices. The effect of energy consumption and equipment investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

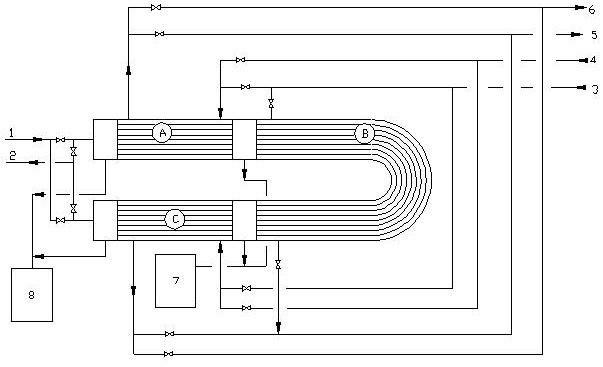

Embodiment 1

[0042] In this embodiment, gasoline loading oil gas 500m 3 / h, the oil and gas loaded on the vehicle are treated by the device of the present invention, the pre-condenser and the deep cooler adopt a single-tube shell and tube heat exchanger, and the oil and gas are pre-cooled to 5°C to remove moisture and high-condensing-point organic matter, and then deep-cooled to - 75°C, the oil and gas recovery rate can be 95%, and the switching operation of two cryocoolers can reduce the energy consumption of the device by 23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com