UV skin-feeling wood coating as well as preparation method and application thereof

A wood coating and skin-feeling technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of high one-time investment cost, high operating cost and insufficient flatness of excimer lamp curing technology, and improve the delicate hand feeling. , Improve the curing speed, the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

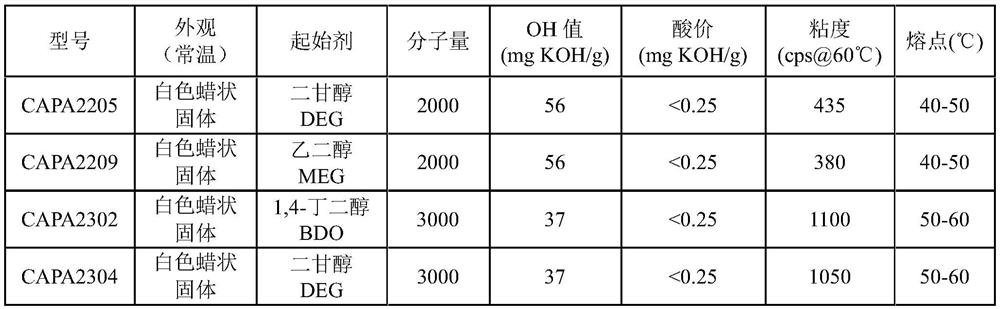

[0066] In a 1000mL four-necked flask, 750 grams of polycaprolactone diol (Perstorp CAPA2302, molecular weight 3000), 70.5 grams (0.5mol) of ethyl isocyanate acrylate, 0.12 grams of dibutyltin dilaurate as a catalyst, and parahydroxyl Take 0.8 g of anisole, slowly heat up to 80°C-85°C for 0.5-4 hours, heat-retain, stir and react for 3-5 hours, and discharge the material to obtain a bifunctional polycaprolactone urethane acrylate with the structure shown in the following formula.

[0067]

[0068] R is: 1,4-butylene (-CH 2 CH 2 CH 2 CH 2 -), that is, the glycol initiator in the polycaprolactone diol is 1,4-butanediol;

[0069] a+b=(3000-90) / 114=25.5263.

Embodiment 2

[0071] In the 6L autoclave, drop into 1340 grams of 2,2-dimethylol propionic acid (C 5 h 10 o 4 , molecular weight 134), 40 grams of sodium formate, warming up to 155 ° C, began to drop ethylene oxide ( Molecular weight 44) 2200 grams for reaction, temperature control 155 ℃ ~ 165 ℃, pressure 0.10 ~ 0.40MPa, dropwise for 3 to 4 hours, after the drop is completed, 155 ℃ ~ 165 ℃ for 2 to 3 hours, and then cooled to below 80 ℃ , discharging to get the crude product; the crude product was added 40 grams of activated clay and stirred for 30 minutes, and filtered to obtain clear and transparent trihydroxy polyether ester (C 15 h 30 o 9 , molecular weight 354) 3469.2 grams, reaction formula, structure as shown in the following formula, wherein: n=2, a+b+c=5.

[0072]

[0073] In the 3000mL four-necked flask, drop into trihydroxy polyether ester (C 15 h 30 o 9 , molecular weight 354) 177 grams, IPDI 333 grams (1.5mol), catalyst dibutyltin dilaurate 0.2 grams, be warming up ...

Embodiment 3

[0082] In a 2000mL four-necked flask, 1000 grams of polyether modified polysiloxane (Zhejiang Xin'an Chemical Industry Group Co., Ltd., a special organic silicon product for UV resin modification, model: 7520, molecular weight 2000), and 141 grams of isocyanate ethyl acrylate ( 1mol), catalyst dibutyltin dilaurate 0.12 grams, polymerization inhibitor p-hydroxyanisole 0.9 grams, 0.5 ~ 4 hours slowly warming up to 80 ℃ ~ 85 ℃ stirring reaction for 3 ~ 5 hours, discharging, obtained 2 functional Polysiloxane type urethane acrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com