A kind of flame retardant, flame retardant PLA composite material and preparation method thereof

A composite material and flame retardant technology, which is applied in the field of flame retardant PLA composite material and its preparation, and flame retardant, can solve the problems of non-environmental protection, poor mechanical properties, and large amount of flame retardant, and achieve excellent flame retardant. performance, improve compatibility, improve the effect of flame retardant performance

Active Publication Date: 2022-05-31

ZHEJIANG UNIV OF TECH

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to overcome the problems that the traditional flame retardant for PLA modification is not environmentally friendly, the addition amount is large, and its mechanical properties will be deteriorated, the present invention provides a flame retardant with good compatibility, environmental friendliness and excellent mechanical properties.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

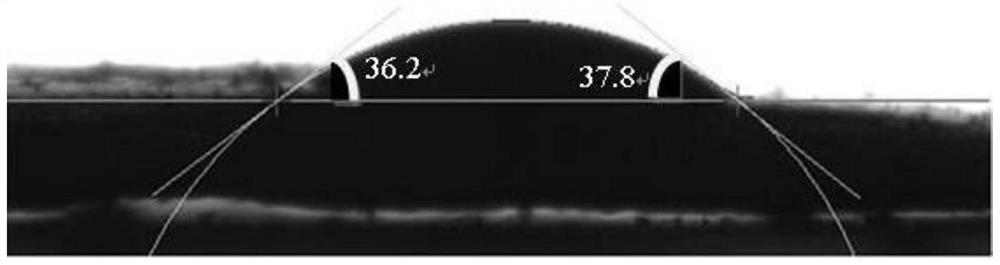

[0051] The flame retardant 0.5g (1.0wt% addition) prepared in implementation 3 and the dried pure PLA 49.5g were mixed uniformly

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

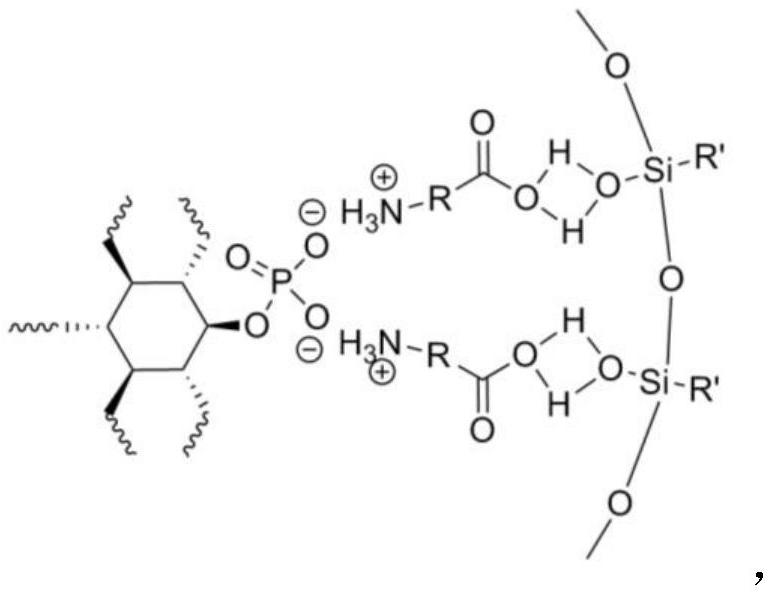

The present invention relates to the technical field of flame retardant design, in particular to a flame retardant, a flame retardant PLA composite material and a preparation method thereof. The flame retardant has the following general structural formula: wherein, NH 2 ‑R‑COOH is the basic amino acid of biomass, Si(OH) 3 ‑R' is the hydrolyzed silane coupling agent. The preparation method of the flame retardant comprises the following steps: (1) adding the phytic acid aqueous solution dropwise to the biomass basic amino acid aqueous solution, adjusting the pH to 6-8, adding the first organic solvent to obtain a precipitate, drying, Product A is obtained; (2) the silane coupling agent is hydrolyzed in the second organic solvent to obtain the hydrolyzed silane coupling agent, and the hydrolyzed silane coupling agent is added to the product A, and the reaction is heated under stirring, and the Filter, wash and dry to obtain the flame retardant. The invention can effectively improve the compatibility between the flame retardant and the PLA material by modifying the surface of the all-bio-based flame retardant with a coupling agent, and can effectively take into account both excellent mechanical properties and excellent flame retardancy, especially at low dosages. performance.

Description

A kind of flame retardant, flame retardant PLA composite material and preparation method thereof technical field The present invention relates to flame retardant design technical field, relate in particular to a kind of flame retardant, flame retardant PLA composite material and preparation thereof. preparation method. Background technique Polylactic acid (PLA) is a biodegradable polymer that can be obtained from renewable resources such as sugar, corn starch, etc. Renewable resin produced in . PLA, as a commercialized bio-based polymer material, has good biocompatibility high performance, mechanical properties, biodegradability and low toxicity, it has full application potential in the electronics, automotive and construction industries. However PLA is highly flammable and has a potential fire threat, which greatly limits the practical application of PLA in industries with high flame retardancy requirements. Therefore, the flame retardant modification of polylac...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08K9/06C08K5/521C08L67/04

CPCC08K9/06C08K5/521C08L2201/02C08L67/04Y02W90/10

Inventor 陈思王旭徐健吴飞洋俞陈诚马猛施燕琴何荟文

Owner ZHEJIANG UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com