Method for preparing ceramsite from oily sludge

A technology of sludge and ceramsite, which is applied in the field of resource treatment of oily sludge, can solve the problems of high cost, lack of reasonable recovery, difficulty in resource utilization of oily sludge, etc. Low, the effect of improving the degree of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

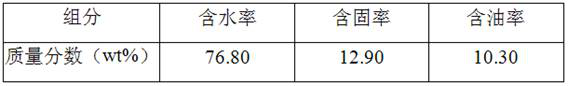

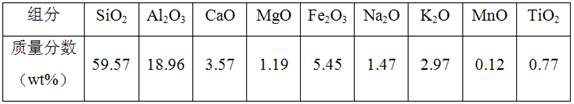

Embodiment 1

[0038] (1) The raw material oily sludge enters the cyclone to remove solids larger than 100 μm in the material; it is mechanically dehydrated by the screw stacker, and the moisture content of the output is tested to be 68.32wt%;

[0039] (2) After heating the discharged material to 170°C with steam, fully mix it with solvent oil at 250~380°C, the ratio of the added amount to the mass of the material is 7:1, and stir at 200r / min for 70min under heat preservation conditions to fully react;

[0040] (3) Let the product of step (2) stand still, and perform solid-liquid separation after the system is layered;

[0041] (4) After the separated liquid phase is separated from oil and water, the petroleum components can be recovered, the solid phase is dried, and 30% hydrogen peroxide solution is added. The mass ratio of hydrogen peroxide solution to solid phase is 1.7:1 After standing for 30 minutes, the solids were separated, granulated, and made into 5mm spherical particles, placed i...

Embodiment 2

[0043] (1) The raw material oily sludge enters the filter to remove solids larger than 100 μm in the material; mechanical dehydration is carried out through the screw stacker, and the moisture content of the discharged material is tested to be 64.02wt%;

[0044] (2) After heating the discharged material to 190°C with steam, fully mix it with solvent oil at 280~400°C, the ratio of the added amount to the material mass is 8:1, and stir at 250r / min for 60min under heat preservation conditions to fully react;

[0045] (3) Let the product of step (2) stand still, and perform solid-liquid separation after the system is layered;

[0046] (4) After the separated liquid phase is separated from oil and water, the petroleum components can be recovered, the solid phase is dried, and 30% hydrogen peroxide solution is added. The mass ratio of hydrogen peroxide solution to solid phase is 1.5:1 After standing for 30 minutes, the solids were separated and granulated to make 8mm spherical parti...

Embodiment 3

[0048] (1) The raw material oily sludge enters the centrifuge to remove solids larger than 100 μm in the material; it is mechanically dehydrated by the screw stacker, and the moisture content of the output is tested to be 58.94wt%;

[0049] (2) After heating the discharged material to 180°C with steam, fully mix it with solvent oil at 150~300°C, the ratio of the added amount to the mass of the material is 8:1, and stir at 230r / min for 80min under heat preservation conditions to fully react;

[0050] (3) Let the product of step (2) stand still, and perform solid-liquid separation after the system is layered;

[0051] (4) After the separated liquid phase is separated from oil and water, the petroleum components can be recovered, the solid phase is dried, and 30% hydrogen peroxide solution is added. The mass ratio of hydrogen peroxide solution to solid phase is 2:1 After standing for 30 minutes, the solid was separated and granulated to make 4mm spherical particles, placed in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com