Bicyclic guanidine salt eutectic solvent catalyst as well as preparation method and application thereof

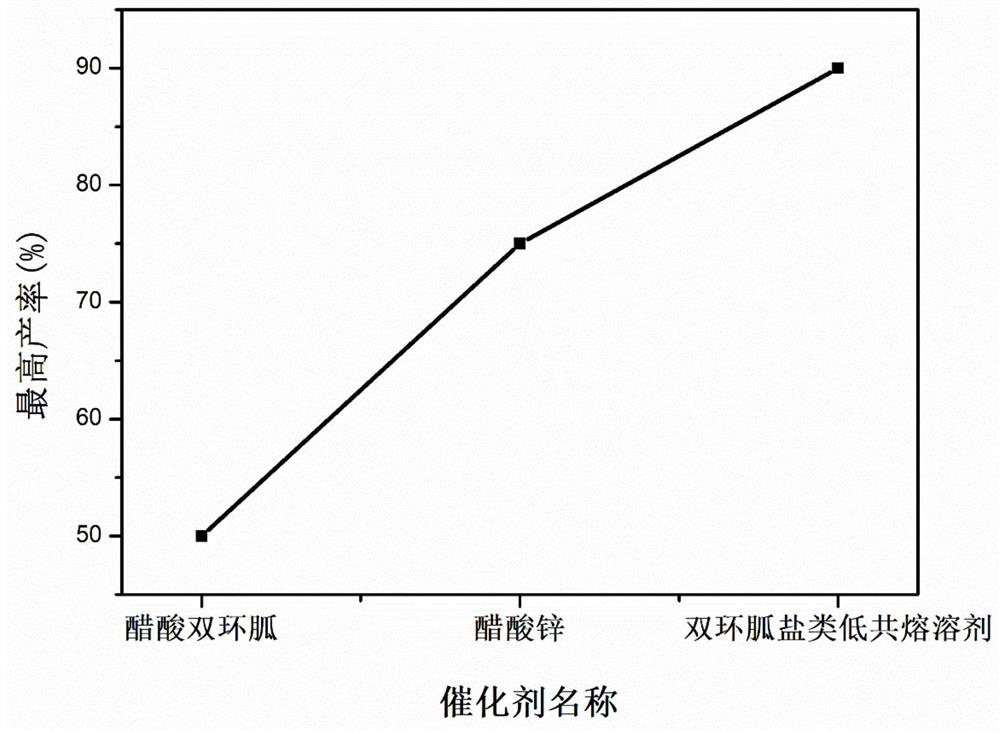

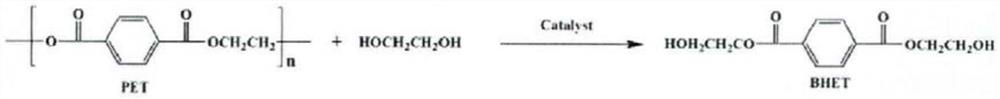

A low eutectic solvent, bicyclic guanidine technology, applied in the field of polymer plastic degradation, green/clean catalysis technology, can solve the problems of low reaction rate, harsh reaction conditions, difficulty in refining products, etc., to achieve stable catalyst, achieve yield, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 20ml of deionized water into the Schleck reactor, and then add 2g of 1,5,7-triazidebicyclo(4.4.0)dec-5-ene. Heat and stir under the protection of high-purity nitrogen. After the system temperature reaches 30°C, add a 4% aqueous hydrochloric acid solution to the kettle dropwise from a constant pressure dropping funnel to control the 1,5,7-triazidebicyclo(4.4.0) The molar ratio of dec-5-ene to hydrochloric acid is 1:2 and stirred. The obtained product was rotary evaporated to remove the contained water, and the solid product was moved into a vacuum drying oven to dry for 48 hours to obtain 2.51 g of a white solid product, namely bicyclic guanidine chloride, with a yield of 98.4%. Then bicycloguanidine chloride and zinc acetate were mixed and stirred at a molar ratio of 1:1, the reaction temperature was 80° C., and the reaction time was 4 hours; the bicycloguanidine chloride / zinc acetate deep eutectic solvent was obtained.

Embodiment 2

[0030] Add 20ml of deionized water into the Schleck reactor, and then add 2g of 1,5,7-triazidebicyclo(4.4.0)dec-5-ene. Heat and stir under the protection of high-purity nitrogen. After the system temperature reaches 30°C, add 4% acetic acid aqueous solution to the kettle dropwise from a constant pressure dropping funnel to control 1,5,7-triazidebicyclo(4.4.0) The molar ratio of dec-5-ene to acetic acid is 1:1 and stirred. The obtained product was rotary evaporated to remove the contained moisture, and the solid product was moved into a vacuum drying oven to dry for 48 hours to obtain 2.49 g of a white solid product, ie, bicyclic guanidine acetate, with a yield of 96.2%. Then bicyclic guanidine acetate and zinc acetate were mixed and stirred at a molar ratio of 1:1, the reaction temperature was 80° C., and the reaction time was 4 hours; a bicyclic guanidine acetate / zinc acetate deep eutectic solvent was obtained.

Embodiment 3

[0032] Add 20ml of deionized water into the Schleck reactor, and then add 2g of 1,5,7-triazidebicyclo(4.4.0)dec-5-ene. Heat and stir under the protection of high-purity nitrogen. After the system temperature reaches 80°C, drop a 4% phosphoric acid aqueous solution into the kettle from a constant pressure dropping funnel to control the 1,5,7-triazidebicyclo(4.4.0) The molar ratio of dec-5-ene to phosphoric acid is 3:1 and stirred. The obtained product was rotary evaporated to remove the contained moisture, and the solid product was moved into a vacuum drying oven to dry for 48 hours to obtain 2.52 g of a white solid product, namely bicyclic guanidine phosphate, with a yield of 95.4%. Then bicyclic guanidine phosphate and zinc acetate were mixed and stirred at a molar ratio of 1:1, the reaction temperature was 80° C., and the reaction time was 4 hours; the bicyclic guanidine phosphate / zinc acetate deep eutectic solvent was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com