Interfacial ionic liquid supported catalyst for synthesizing cyclic carbonate from carbon dioxide

A supported catalyst, cyclic carbonate technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of harsh recovery conditions and expensive catalysts, etc. Achieve the effect of low cost of raw materials, large industrial application value and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The interface ionic liquid loading type (ZnBr) prepared in this embodiment 2 / IL@HNTs) catalyst. The preparation method of this type of supported catalyst, concrete steps are:

[0038] Step 1, weigh zinc bromide, 1-butyl-3-methylimidazolium bromide and halloysite with a mass ratio of 1:2:0.8 in a single-mouthed round-bottomed flask for subsequent use;

[0039] Step 2. Place the round bottom flask under a nitrogen atmosphere, heat it to 100°C with an oil bath, and stir it mechanically for 12 hours;

[0040] Step 3, after the reaction is over, centrifuge and wash the product 3 times with absolute ethanol;

[0041] Step 4. Put the sample in a vacuum drying oven at 60°C overnight. After drying, grind the sample and store it sealed for future use.

Embodiment 2

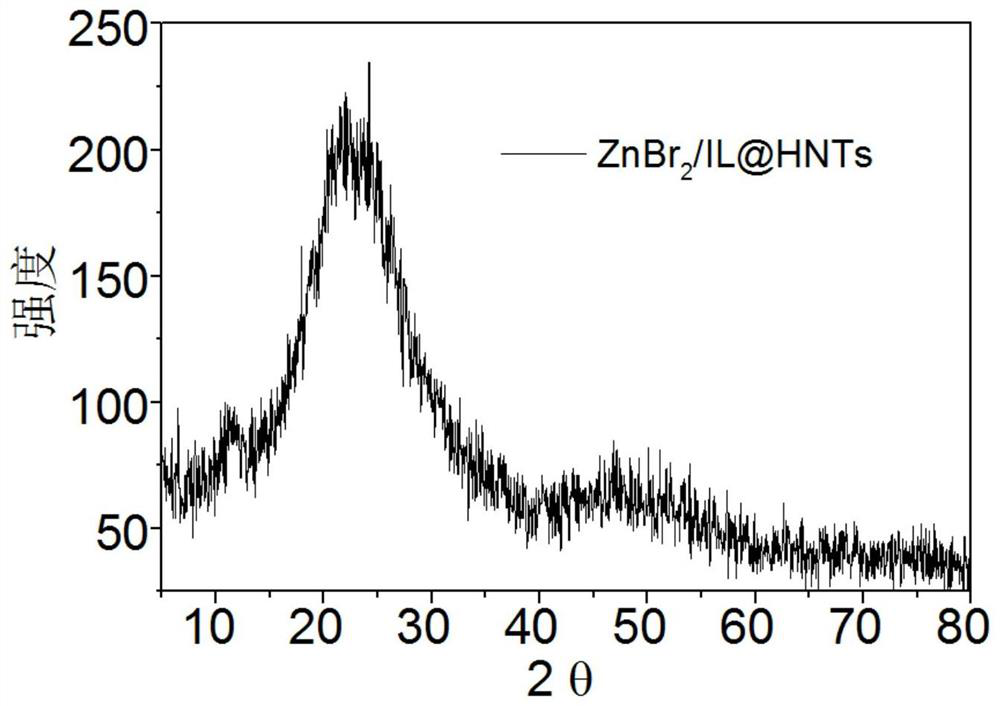

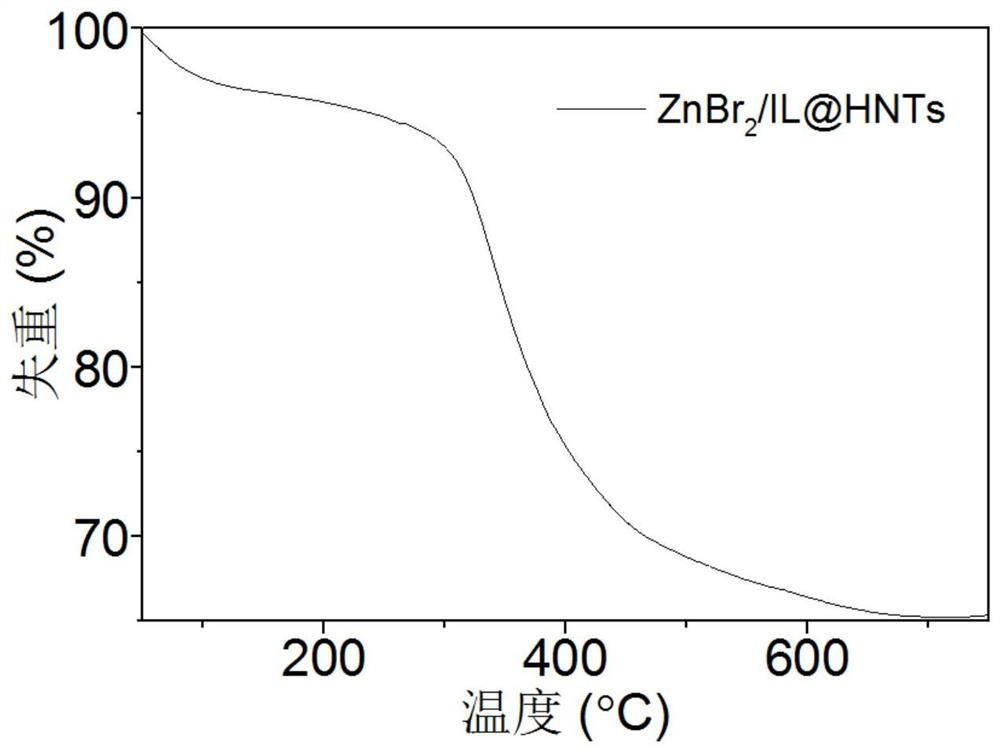

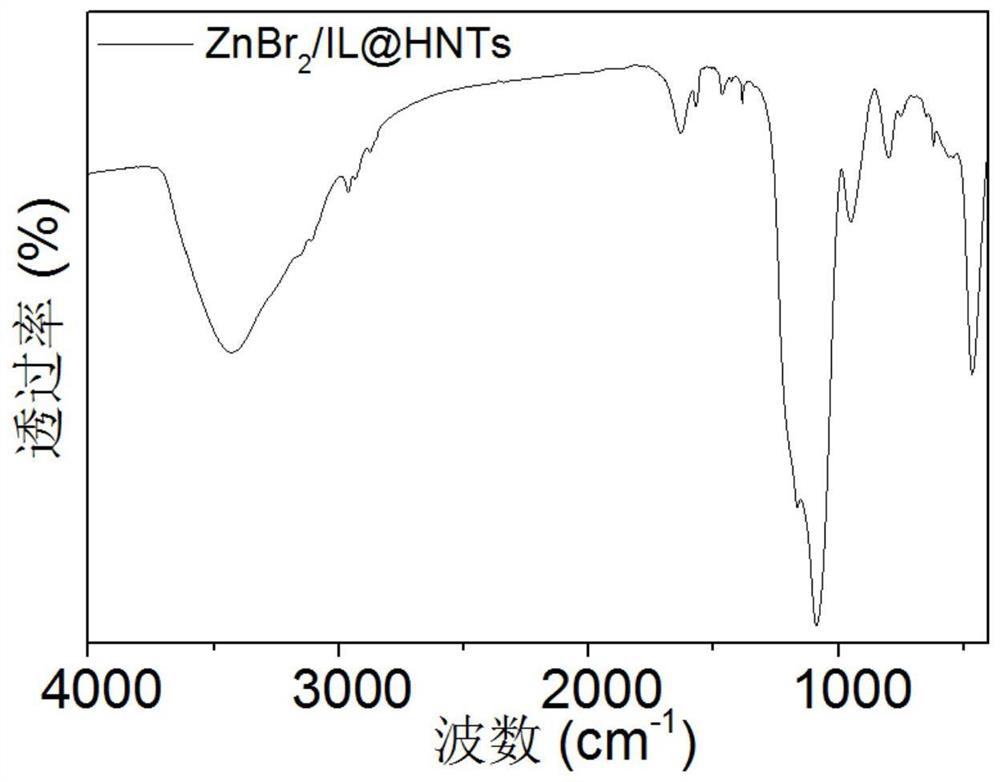

[0043] Structural characterization of ZnBr2 / IL@HNTs catalyst, XRD, TG, Fourier transform infrared and N 2 Adsorption and desorption are as figure 1 , figure 2 , image 3 and Figure 4 shown.

Embodiment 3

[0045] An application for synthesizing a cyclic carbonate by using an interfacial ionic liquid supported catalyst, the specific steps are:

[0046] Step 1, clean up the autoclave, get the ZnBr prepared in example 1 2 / IL@HNTs catalyst 0.1g was put into a 100mL autoclave, and then 8.217g of propylene oxide was added to it, and the catalyst accounted for 1.21wt.% of propylene oxide;

[0047] Step 2. While keeping the reactor airtight, slowly introduce 3.0MPa CO into it 2 Gas, react at 120°C for 2h;

[0048] Step 3. After the reaction is completed, extract and separate with dichloromethane, take a small amount of product and conduct qualitative and quantitative analysis by gas chromatography. The formation rate of the product propylene carbonate is measured to be 98.98%, and the selectivity is >99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com