Physiologically sustained-release amino acid-balanced feed for tilapia mossambica

An amino acid and tilapia technology, applied in the field of feed, can solve the problems of unsmooth feeding, poor protein efficiency, low economic benefits, etc., and achieve the effects of shortening cooling time, improving production efficiency and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as figure 1 Shown, a kind of tilapia feed of physiological slow-release amino acid balance, the tilapia feed of this physiological slow-release amino acid balance is made up of the composition of following parts by weight: petroleum protein liquid 35~42 parts, soybean oil 3.6~10.4 parts, 33~58 parts of starch, 1.3~3.2 parts of multivitamins, 1~2.5 parts of compound mineral salts, 0.1~0.5 parts of resveratrol, 3.5~4.5 parts of carboxymethyl cellulose, 1.2-2.4 parts of glycine and 0.3 parts of arginine ~2.3 servings.

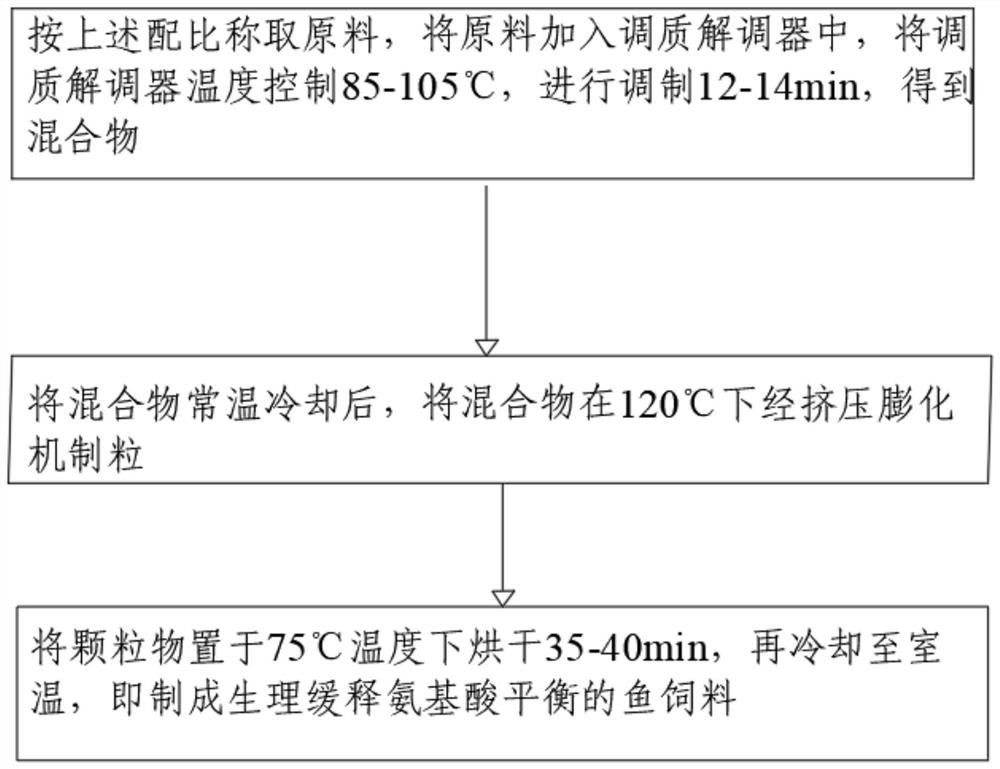

[0045] A preparation process of a physiological slow-release amino acid balance tilapia feed, the preparation process steps are as follows:

[0046] Step 1. Weigh the raw materials according to the above ratio, add the raw materials into the tempering demodulator, control the temperature of the tempering demodulator to 85-105°C, and perform modulation for 12-14 minutes to obtain a mixture;

[0047] Step 2, after cooling the mixture to normal temperat...

Embodiment 2

[0051] Embodiment 2 is a further improvement to Embodiment 1.

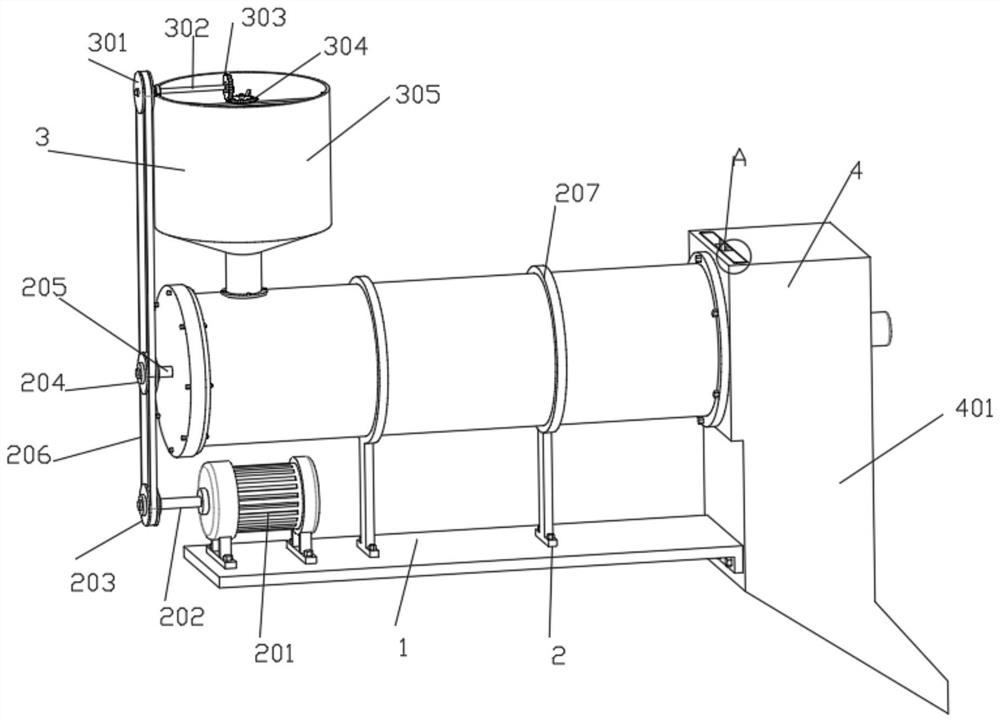

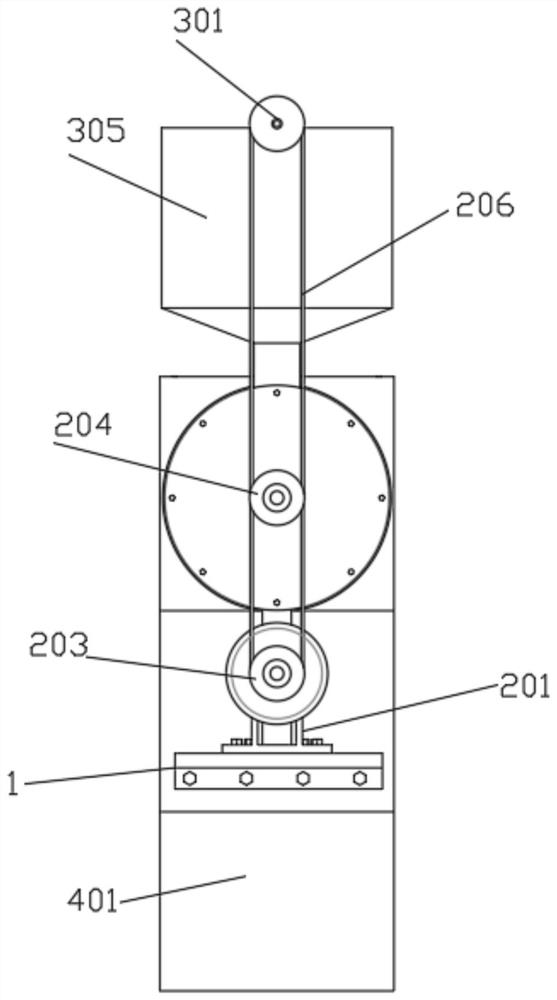

[0052] Such as figure 2 , 3 , 4, 5, 6, 7, 10, and 11 show a device for a physiological slow-release amino acid balanced tilapia feed, including a base 1, the top of which is connected with an extruded structure 2 for feed extruded granulation, The puffing structure 2 comprises a first driving motor 201, a first rotating shaft 202, a first pulley 203, a second pulley 204, a second rotating shaft 205, a first belt 206, an expanding cylinder 207, a granulating plate 208 and an auger 209, the first The drive motor 201 is fixedly mounted on the top of the base 1, the output end of the first drive motor 201 is fixedly connected with the first rotating shaft 202, the outer end of the first rotating shaft 202 is fixedly connected with the first pulley 203, and the first pulley 203 is movably connected with the first pulley 203. A belt 206, the first belt 206 is movably connected with a second pulley 204, the second rot...

Embodiment 3

[0056] Embodiment 3 is a further improvement to Embodiment 1.

[0057] Such as Figure 4 , 8 , 9, the left end of the discharge box 401 is connected with an installation structure 5 for the installation of the granulation plate 208, and the installation structure 5 includes a limit block 501, a triangular groove 502, a triangular insert 503, a limit chute 504, an L-shaped Bar 505, spring 506, transverse groove 507, jack 508 and straight groove 509, jack 508 is offered at the left end of discharge box 401, and the sidewall of jack 508 offers limit chute 504, and the side of limit chute 504 The upper end of the wall is provided with a triangular groove 502, and the outer wall of the granulation plate 208 is fitted and slidably connected with the side wall of the socket 508, and the outer wall of the granulation plate 208 is fixedly connected with a limit block 501 used in conjunction with the limit chute 504, forming The upper side wall of the particle board 208 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com