Powder grinding aid adding device

A technology of adding devices and grinding aids, which is applied in the direction of conveyor control devices, packaging, loading/unloading, etc., and can solve the problems of different performance, different, easy to stick, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

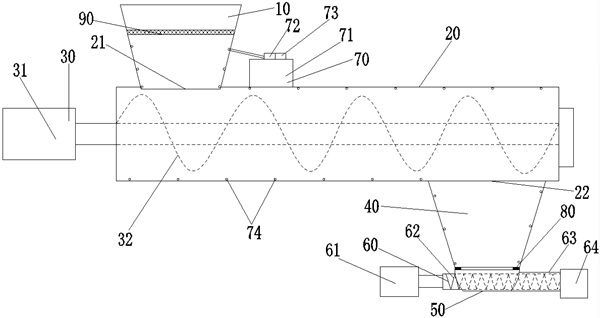

[0017] Such as figure 1 As shown, the powder grinding aid adding device includes a hopper 10, a hopper 20, a screw conveying mechanism 30, a buffer hopper 40, a buffer hopper 50, a twin-screw discharge device 60, an air cannon device 70 and a control system, wherein A first feed port 21 and a first discharge port 22 are provided on the feed bin 20, and the hopper 10 is connected to the feed bin 20 through the first feed port 21; the screw conveying mechanism 30 includes a first drive motor 31 and a screw blade 32 , the helical blade 32 is driven by the first driving motor 31 to rotate in the silo 20, so as to forcefully push the powder grinding aid added into the hopper 20 through the hopper 10 to the first outlet 22, and the first outlet The feed port 22 is set at the lower part of the hopper 20, so that the powder grinding aid in the hopper 20 can smoothly fall into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com