Battery diaphragm, preparation method thereof and battery

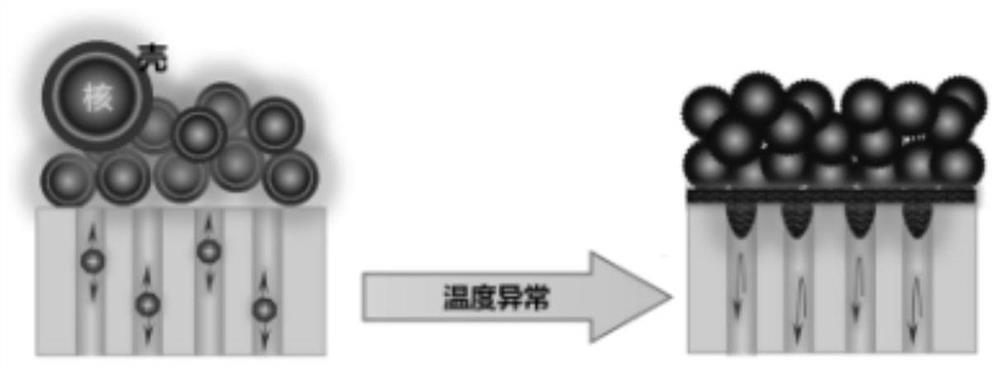

A technology of battery separator and base film, which is applied in secondary batteries, battery pack components, and secondary battery repair/maintenance, etc., can solve the problems of smaller surface area of the diaphragm, internal short circuit, thermal runaway, etc., to suppress thermal runaway. , the effect of increasing the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

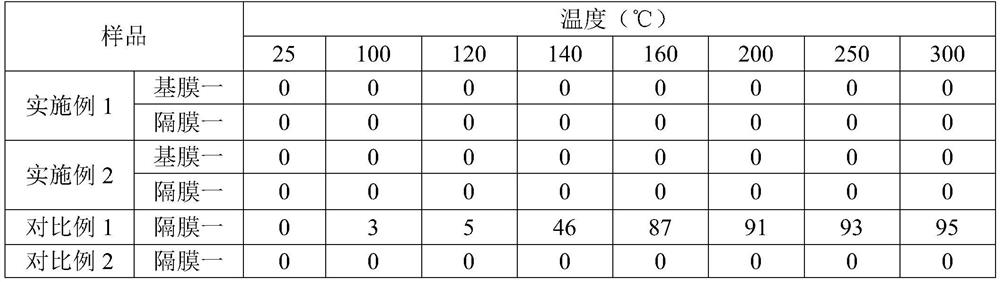

Embodiment 1

[0069] 1. Preparation of battery separator

[0070] Step 1: Preparation of polymer base film

[0071] 1) Take 15g of polym-phenylene isophthalamide, dissolve it in 85g of dimethylformamide solvent, then add 35wt% polyvinyl alcohol and 7wt% alumina as additives to prepare a solution, and let it stand for 24 hours to prepare Liquid film;

[0072] 2) Put the liquid film in a mixed solution of methylpyrrolidone and ethanol (volume ratio=8:1) to react for 24 hours to obtain a gel state film;

[0073] 3) At a stretch ratio of 135%, the gel state film is stretched and oriented by bidirectional simultaneous stretching;

[0074] 4) placing the oriented gel film in a mixed solution of hydrogen peroxide and water (volume ratio=3:7) for 72 hours to obtain a solid film;

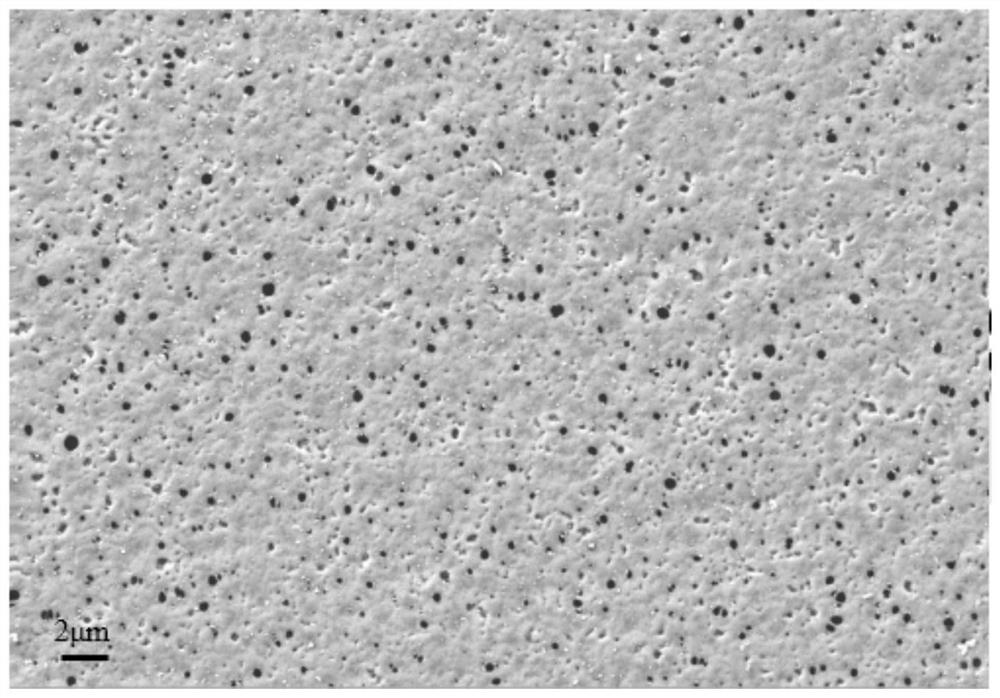

[0075] 5) After rolling the solid film at 120°C, place it in a blast oven at 250°C and heat it for 10 hours to obtain a 16 μm thick polym-phenylene isophthalamide base film. The average pore diameter of the base film i...

Embodiment 2

[0109] 1. Preparation of battery separator

[0110] Step 1: Preparation of polymer base film

[0111] 1) Take 17.5g of polyamic acid, dissolve it in 100g of dimethylformamide solvent, add 50wt% polyethylene glycol (PEG600) and 3wt% graphene as additives, prepare a solution, and let it stand for 24h to form a liquid film ;

[0112] 2) Put the liquid film in a mixed solution of isopropanol, dimethylformamide and toluene (volume ratio=5:4:1) to react for 24 hours to obtain a gel film;

[0113] 3) By bidirectional asynchronous stretching, the transverse stretching ratio is 120%, and the longitudinal stretching ratio is 150%, and the gel state film is stretched and oriented;

[0114] 4) placing the oriented gel state film in a mixed solution of n-octane and toluene (volume ratio = 1:1) for 24 hours to obtain a solid film;

[0115] 5) React the solid film at 80°C, 120°C, 150°C, 180°C, 200°C, 220°C, 250°C, 280°C, 300°C for 10h, 2h, 2h, 2h, 1h, 1h, 0.5h, After 0.5 h and 2 h, a pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com