A kind of modified nylon powder and its preparation method and application

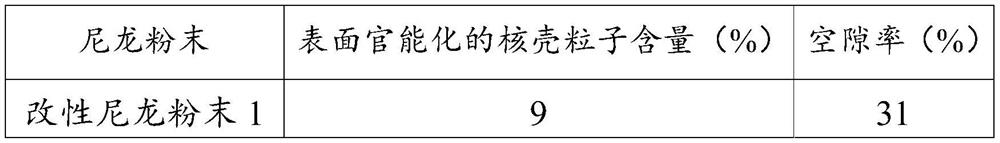

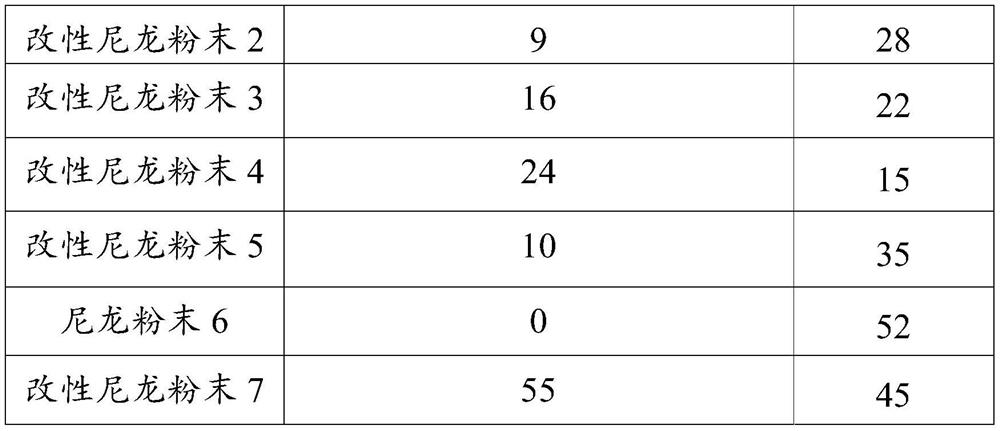

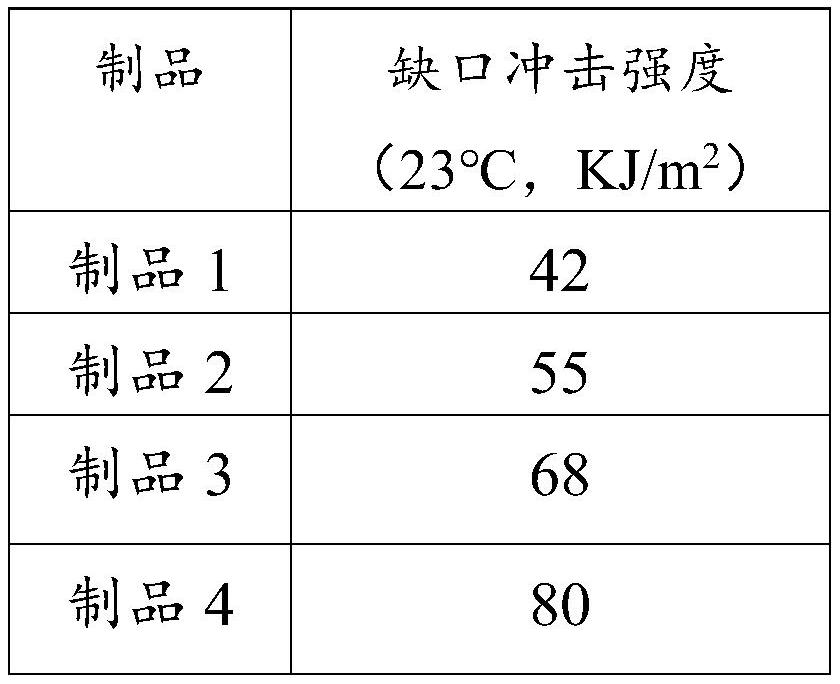

A technology of modifying nylon and powder, applied in the field of 3D printing, can solve the problems of three-dimensional parts defects, insufficient, mechanical properties can not meet the application requirements, etc., to achieve the effect of reducing the porosity and broadening the application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Add 6kg of core-shell particles CSR-1 and 18kg of deionized water into the autoclave, raise the temperature to 150°C, stir at constant temperature for 10 hours, and separate the solid and liquid by high-pressure flash evaporation. After drying, surface carboxylated core-shell particles are obtained;

[0058] (2) Add 3kg of surface carboxylated core-shell particles to 30kg of hexamethylenediamine ethanol solution with a concentration of 10wt%, raise the temperature to 150°C, and perform the amination reaction for 4h, then cool down to 70°C, and centrifuge, After drying, surface-functionalized core-shell particles were obtained with an amine grafting rate of 4%;

[0059] (3) Weigh 1.5 kg of surface-functionalized core-shell particles and mix them with 0.17 kg of compound antioxidant (the mass ratio of 1098 and 168 is 1:2), add them to 3.7 kg of ethanol, and obtain surface functionalized particles after ultrasonic dispersion for 5 hours. liquefied core-shell particle ...

Embodiment 2

[0063] (1) Add 6kg of core-shell particles CSR-2 and 18kg of deionized water into the autoclave, raise the temperature to 200°C, stir at constant temperature for 4 hours, and separate the solid and liquid by high-pressure flash evaporation. After drying, surface carboxylated core-shell particles are obtained;

[0064] (2) Add 1.5 kg of surface carboxylated core-shell particles to 6 kg of an ethanol solution of pentamethylenediamine with a concentration of 18 wt%, raise the temperature to 185°C, perform the amination reaction for 2 hours, then cool down to 70°C, and centrifuge , drying to obtain surface-functionalized core-shell particles, the grafting rate of amine groups is 10%;

[0065] (3) Weigh 1.5 kg of surface-functionalized core-shell particles and mix them with 0.17 kg of compound antioxidant (the mass ratio of 1098 and 168 is 1:2), add them to 2.8 kg of ethanol, and obtain surface functionalized particles after ultrasonic dispersion for 5 hours. liquefied core-shell ...

Embodiment 3

[0069] (1) Add 6kg of core-shell particles CSR-1 and 18kg of deionized water into the autoclave, raise the temperature to 250°C, stir at constant temperature for 4 hours, and separate the solid and liquid by high-pressure flash evaporation. After drying, surface carboxylated core-shell particles are obtained;

[0070] (2) Add 4kg of surface carboxylated core-shell particles to 10kg of ethanol solution of p-xylylenediamine with a concentration of 25wt%, raise the temperature to 220°C, perform the amination reaction for 2h, cool down to 70°C, pass centrifugation and drying to obtain surface-functionalized core-shell particles with an amine group grafting rate of 15%;

[0071] (3) Weigh 2.87kg of surface-functionalized core-shell particles and mix them with 0.05kg of compound antioxidant (the mass ratio of 1098 and 168 is 1:2), add them to 6.5kg of ethanol, and obtain surface functionalized particles after ultrasonic dispersion for 5 hours liquefied core-shell particle dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com