Novel infiltration treatment process for die-casting plate

A treatment process and plate technology, which is applied in the field of new impregnation treatment process for die-casting plates, can solve problems such as micropores and poor effects, and achieve the effects of improving compactness, promoting penetration, and preventing backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

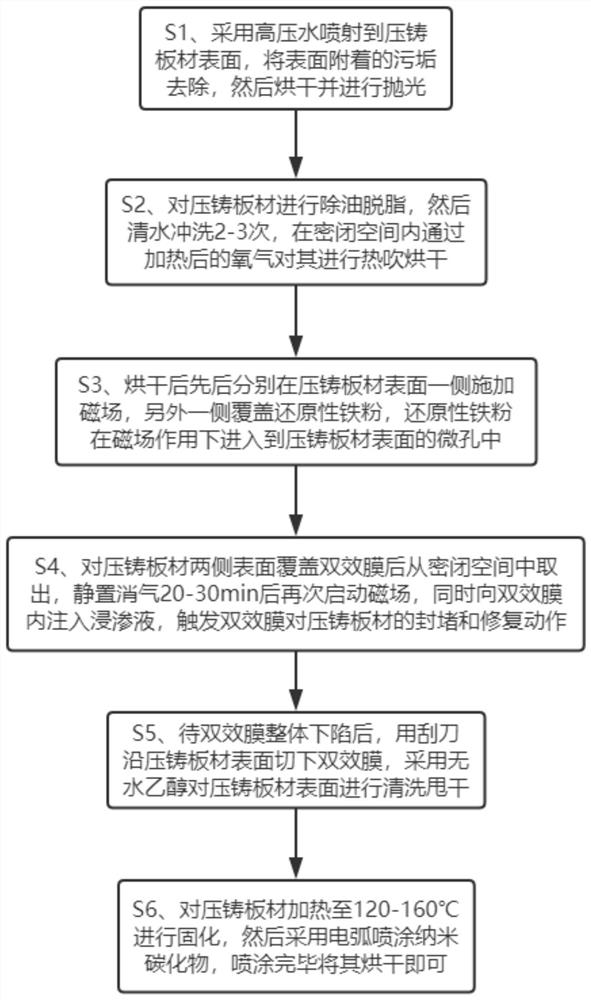

[0046] see figure 1 , a novel impregnation treatment process for die-casting plates, comprising the following steps:

[0047] S1. Use high-pressure water to spray onto the surface of the die-casting plate to remove the dirt attached to the surface, then dry and polish;

[0048] S2. Degrease and degrease the die-casting plate, rinse it twice with clean water, and dry it with heated oxygen in a closed space;

[0049] S3. After drying, a magnetic field is applied to one side of the surface of the die-casting sheet, and the other side is covered with reduced iron powder, and the reduced iron powder enters the micropores on the surface of the die-casting sheet under the action of the magnetic field;

[0050] S4. Cover the surface of both sides of the die-casting plate with a double-effect film and take it out of the closed space. After standing still for 20 minutes, start the magnetic field again, and at the same time inject impregnating liquid into the double-effect film to trigg...

Embodiment 2

[0063] A novel impregnation treatment process for die-casting plates, comprising the following steps:

[0064] S1. Use high-pressure water to spray onto the surface of the die-casting plate to remove the dirt attached to the surface, then dry and polish;

[0065] S2. Degrease and degrease the die-casting plate, rinse it with clean water for 3 times, and dry it with heated oxygen in a closed space;

[0066] S3. After drying, a magnetic field is applied to one side of the surface of the die-casting sheet, and the other side is covered with reduced iron powder, and the reduced iron powder enters the micropores on the surface of the die-casting sheet under the action of the magnetic field;

[0067] S4. Cover the surface of both sides of the die-casting plate with a double-effect film and take it out of the confined space. After standing still for 25 minutes, start the magnetic field again, and at the same time inject impregnating liquid into the double-effect film to trigger the d...

Embodiment 3

[0073] A novel impregnation treatment process for die-casting plates, comprising the following steps:

[0074] S1. Use high-pressure water to spray onto the surface of the die-casting plate to remove the dirt attached to the surface, then dry and polish;

[0075] S2. Degrease and degrease the die-casting plate, rinse it with clean water for 3 times, and dry it with heated oxygen in a closed space;

[0076] S3. After drying, a magnetic field is applied to one side of the surface of the die-casting sheet, and the other side is covered with reduced iron powder, and the reduced iron powder enters the micropores on the surface of the die-casting sheet under the action of the magnetic field;

[0077] S4. Cover the surface of both sides of the die-casting plate with a double-effect film and take it out of the confined space, let it stand for degassing for 30 minutes and then start the magnetic field again. repair action;

[0078] S5. After the double-effect film sinks as a whole, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com