Special flour for pure rice steamed vermicelli roll and preparation method of special flour

A technology of special powder and intestine powder, which is applied in the field of pure rice intestine powder special powder and its preparation, to achieve the effect of convenient use, reduction of production process, and expansion of the audience

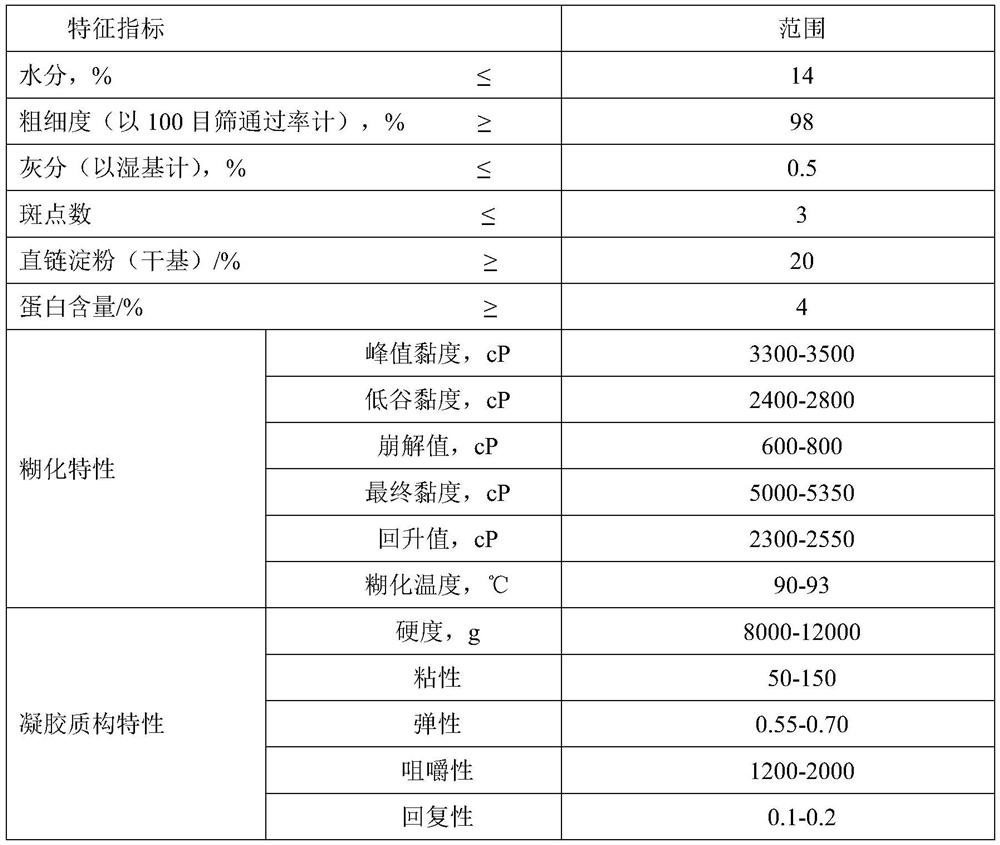

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

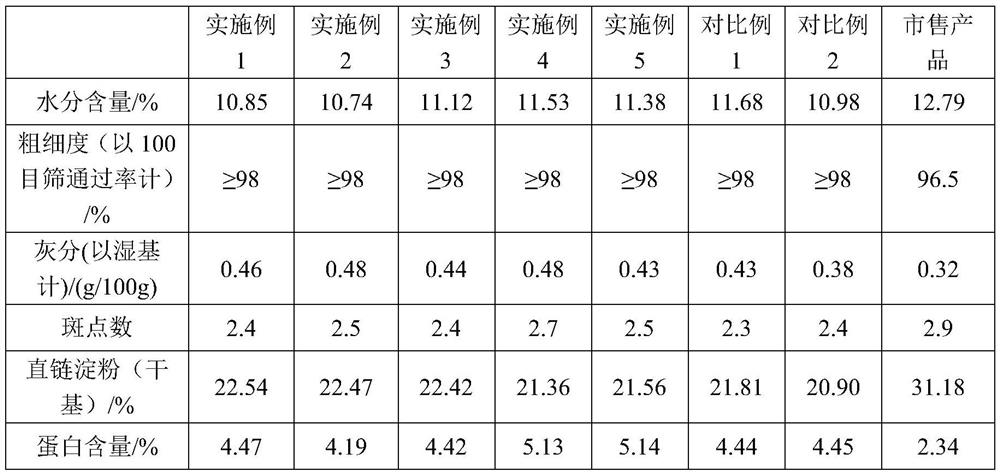

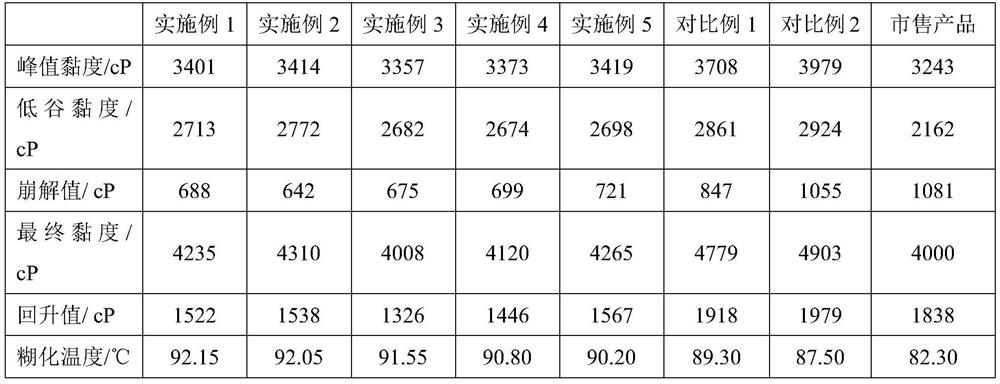

Examples

Embodiment 1

[0027] (1) Soaking rice and refining: Weigh 450g of early indica rice and 50g of late indica rice, add 1500mL of deionized water, soak at room temperature for 2h, and pass through colloidal grinding for 3min to obtain rice milk;

[0028] (2) Enzymolysis and toughening: adjust the pH of the rice milk obtained in step (1) to 5, put the rice milk at 50°C for 30 minutes, add 2.5g protein glutaminase, and keep it warm for 16 hours to carry out enzymatic hydrolysis-toughening Synchronous processing;

[0029] (3) Dehydration and drying: the rice milk obtained in step (2) is vacuum filtered and dehydrated, and the filter cake is dried overnight in an oven at 45° C. After drying, it is pulverized and passed through an 80-mesh sieve to obtain pure rice intestine powder special powder.

Embodiment 2

[0031] (1) Soaking rice and refining: Weigh 475g of early indica rice and 25g of glutinous rice, add 2000mL of deionized water, soak at room temperature for 2h, and pass through colloidal grinding for 3min to obtain rice milk;

[0032] (2) Enzymolysis and toughening: Adjust the pH of the rice milk obtained in step (1) to 6, place the rice milk at 65°C for 30 minutes, add 1.5g of protein glutaminase, and keep it warm for 20 hours to carry out enzymatic hydrolysis-toughening Synchronous processing;

[0033] (3) Dehydration and drying: the rice milk obtained in step (2) was centrifugally dehydrated, and the precipitate was dried overnight in an oven at 50° C., and after drying, it was crushed through an 80-mesh sieve to obtain pure rice intestine powder special powder.

Embodiment 3

[0035] (1) Soaking rice and refining: Weigh 450g of early indica rice and 50g of japonica rice, add 2500mL of deionized water, soak at room temperature for 2h, pass colloidal grinding and refining for 3min, and obtain rice milk;

[0036] (2) Enzymolysis and toughening: adjust the pH of the rice milk obtained in step (1) to 8, place the rice milk at 60°C for 30 minutes, add 2.5g protein glutaminase, and keep it warm for 18 hours to carry out enzymatic hydrolysis-toughening Synchronous processing;

[0037] (3) Dehydration and drying: the rice milk obtained in step (2) was centrifugally dehydrated, and the precipitate was dried overnight in an oven at 55° C. After drying, it was crushed through a 100-mesh sieve to obtain pure rice intestine powder special powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com