Vapor chamber

A technology of vapor chamber and capillary structure, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, heat exchange equipment, etc., and can solve the problem of heat dissipation efficiency failure of the vapor chamber, accumulation in a narrow area or difficulty in passing through a narrow area and reflowing To the position where the vapor chamber is in thermal contact with the heat source, etc., to achieve the effect of improving the heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

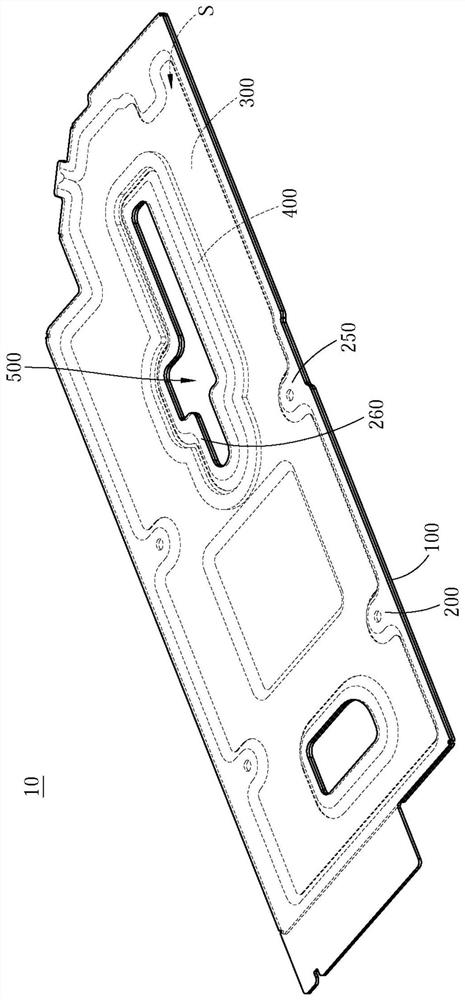

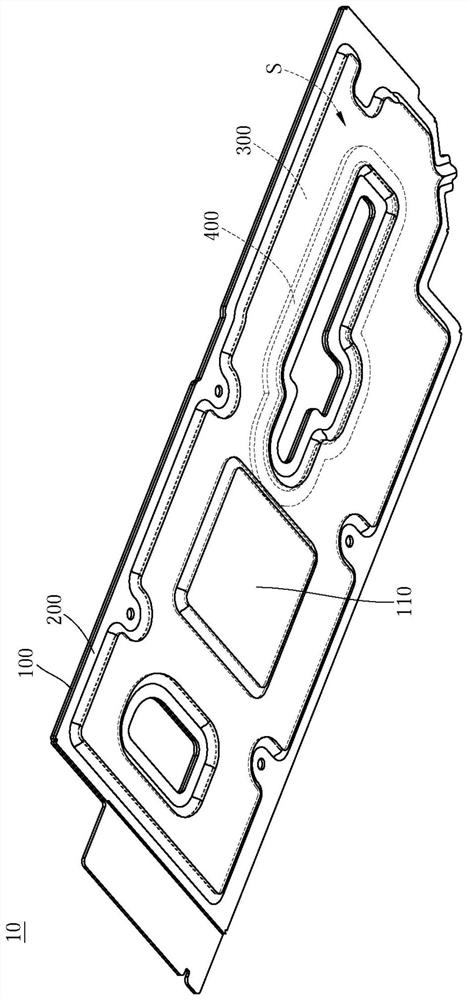

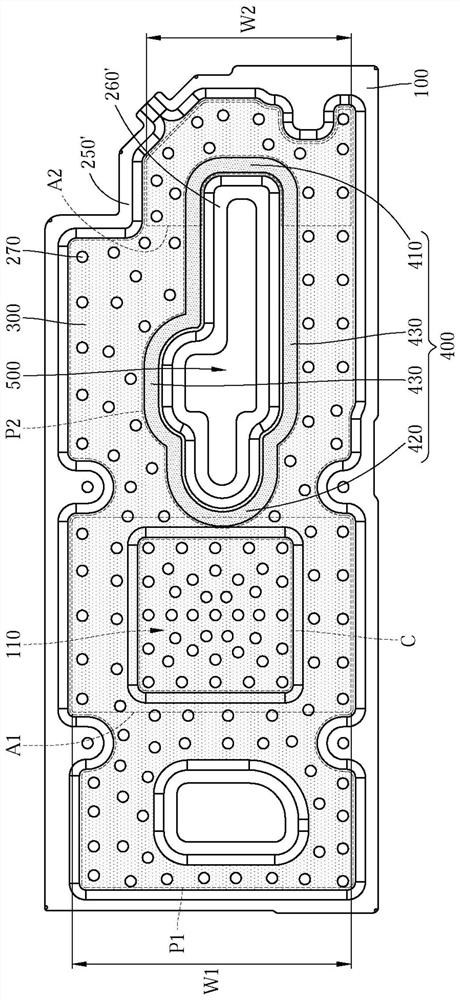

[0049] see Figure 1 to Figure 4 . figure 1 It is a perspective view of the temperature chamber according to the first embodiment of the present invention. figure 2 for figure 1 A perspective view of the vapor chamber of . image 3 for figure 1 Plan view of the vapor chamber with the second cover removed. Figure 4 for figure 1 sectional view.

[0050] The vapor chamber 10 of this embodiment is used for accommodating a cooling fluid (not shown in the figure). The vapor chamber 10 includes a first cover 100 , a second cover 200 , a first capillary structure 300 and a second capillary structure 400 .

[0051] The material of the first cover 100 and the second cover 200 is, for example, oxygen-free copper, silicon-containing alloy copper or phosphorus-containing alloy copper plate, and the second cover 200 and the first cover 100 are joined together to form a liquid-tight The space S, the liquid-tight space S is used to accommodate cooling fluid (not shown in the figure)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com