A kind of wooden round soup spoon arc cutting and grinding equipment

A round soup and arc cutting technology, which is applied to the field of arc cutting and grinding equipment for wooden round soup spoons, can solve the problems of low safety factor, easy damage to the eyes, and inability to collect wood chips in a centralized manner, so as to avoid close-range operations, reduce occupancy, The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

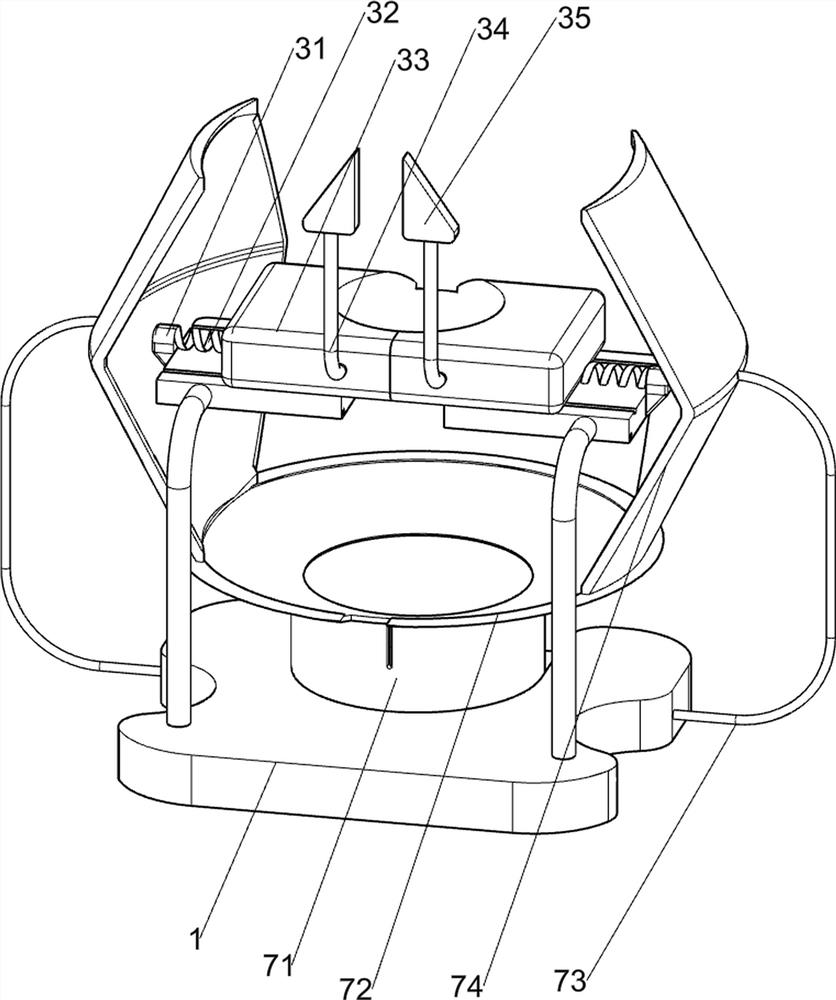

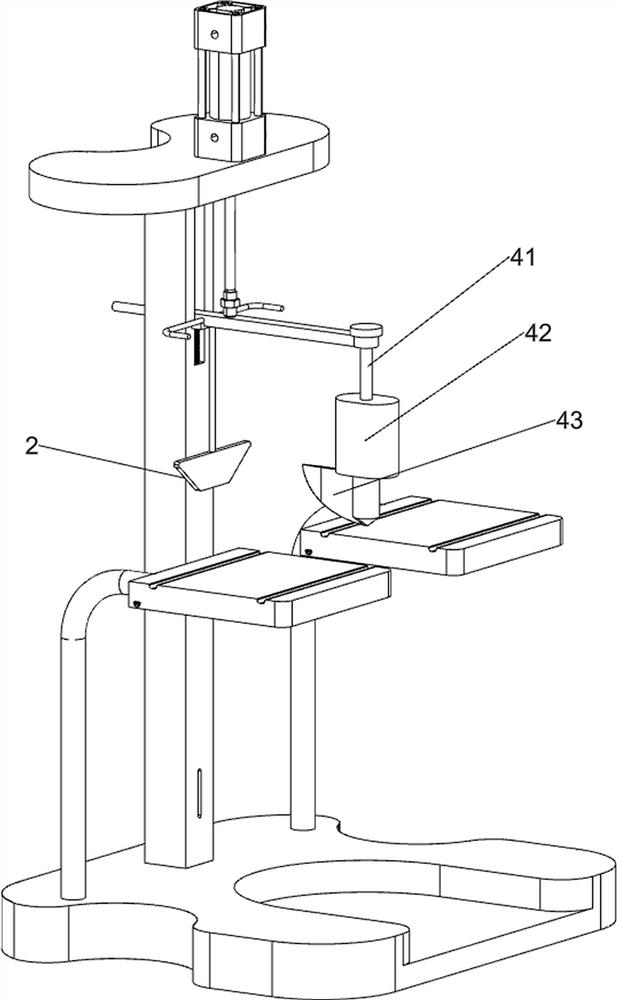

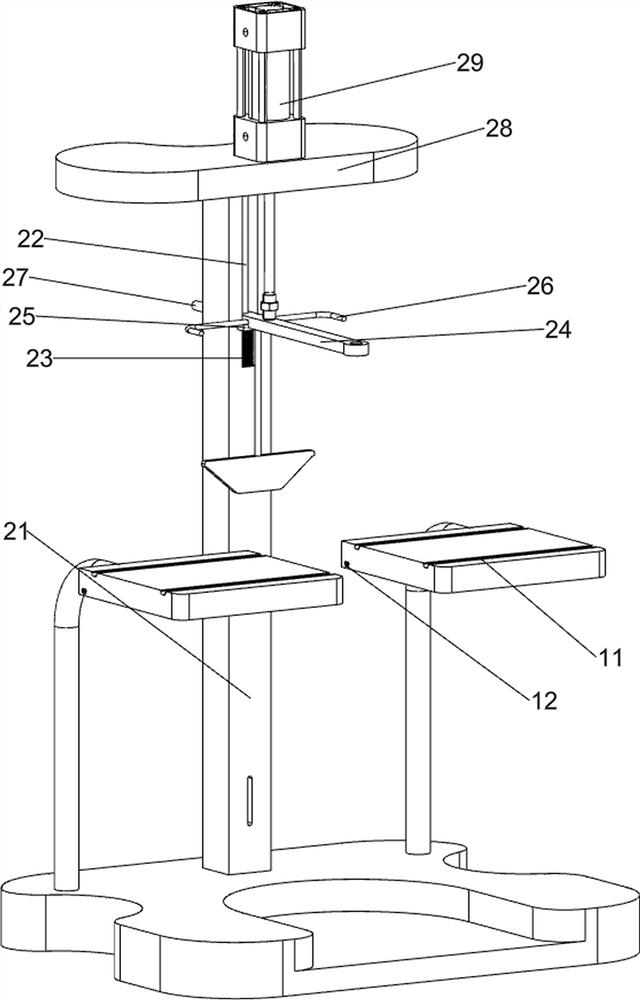

[0064] A wooden round soup spoon arc cutting and grinding equipment, such as Figure 1-4 As shown, it includes a base 1, a sliding rail 11, a through hole 12, a driving mechanism 2, a fixing mechanism 3 and a grinding mechanism 4. The upper part of the rear side of the base 1 is symmetrically provided with a sliding rail 11, and the inner and rear sides of the sliding rail 11 are open Hole 12, a driving mechanism 2 is provided on the rear side of the base 1, a fixing mechanism 3 is provided between the top of the slide rail 11, the fixing mechanism 3 is matched with the driving mechanism 2, and the driving mechanism 2 is provided with a grinding mechanism 4, and the grinding mechanism 4 Including a third connecting rod 41, a grinder 42 and a grinding knife 43, the drive mechanism 2 is provided with a third connecting rod 41, the bottom of the third connecting rod 41 is provided with a grinder 42, and the lower side of the grinder 42 is provided with a grinding knife 43.

[00...

Embodiment 2

[0069] On the basis of Example 1, as image 3 , Figure 5 and Image 6 As shown, it also includes a carrier mechanism 5. The carrier mechanism 5 includes a third connecting block 51, a third spring 52, a connecting plate 53, a carrier frame 54, a brush 55, a fourth connecting rod 56, and a sliding rod 57. , the fifth connecting rod 58 and the second inclined block 59, the bottom of the slide rail 11 is provided with a third connecting block 51, the interior of the through hole 12 is slidably connected with a sliding rod 57, and the lower side of the sliding rod 57 is provided with a connecting plate 53 A third spring 52 is connected between the outer side of the connecting plate 53 and the third connecting block 51 on the same side, the top front side of the connecting plate 53 is provided with a carrier frame 54, and the bottom front side of the slide rail 11 is a fourth connecting rod 56 , the bottom of the fourth connecting rod 56 is provided with a brush 55, the brush 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com