Hollow polymeric carbon nitride catalyst and application thereof in synthesis of acetaldehyde by photocatalytic reduction of CO2

A polymerized, carbon nitride technology, applied in the field of photocatalysis, can solve the problems of mercury pollution, equipment corrosion, and large consumption of raw materials in the ethanol oxidation method, and achieve the effects of stable catalytic activity and high selectivity to acetaldehyde.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a hollow polymeric carbon nitride catalyst, comprising the following steps: adding a certain amount of dicyandiamide and N,N-diethylacetamide into water, mixing, heating and stirring to obtain dicyandiamide and N,N- Diethylacetamide mixed aqueous solution, transfer the mixed aqueous solution of dicyandiamide and N,N-diethylacetamide to a hydrothermal reaction container, place it in an oven for hydrothermal reaction, and after cooling to room temperature naturally, the obtained The product was washed three times with ethanol and distilled water, and then dried in an oven to obtain a supramolecular intermediate, which was transferred to a porcelain crucible and calcined at a high temperature in a muffle furnace to obtain a hollow polymeric carbon nitride catalyst .

[0025] In the present invention, N,N-diethylacetamide is a reducing agent modified dicyandiamide. In the present invention, there is no special limitation on the sources of N,N-diethyl...

Embodiment 1

[0030] A preparation method of a hollow polymerization type carbon nitride catalyst, comprising the steps of:

[0031] Add dicyandiamide and N,N-diethylacetamide into water to form a mixed aqueous solution, the mass concentration of dicyandiamide in the mixed aqueous solution is 1g / L, and the volume fraction of N,N-diethylacetamide is 0.05%. After heating and stirring for 0.1h, transfer it to a hydrothermal reaction kettle, place it in an oven and heat it to 100°C, and react for 5h. Self-assembly formation mechanism, after naturally cooling to room temperature, the resulting product was washed three times with ethanol and distilled water, placed in an oven, and dried at a temperature of 50°C for 6 hours to obtain a supramolecular intermediate, the supramolecular intermediate Transfer to a porcelain crucible and place in a muffle furnace at 400°C for high temperature calcination for 2 hours to obtain a polymeric carbon nitride catalyst PCN-N 1 .

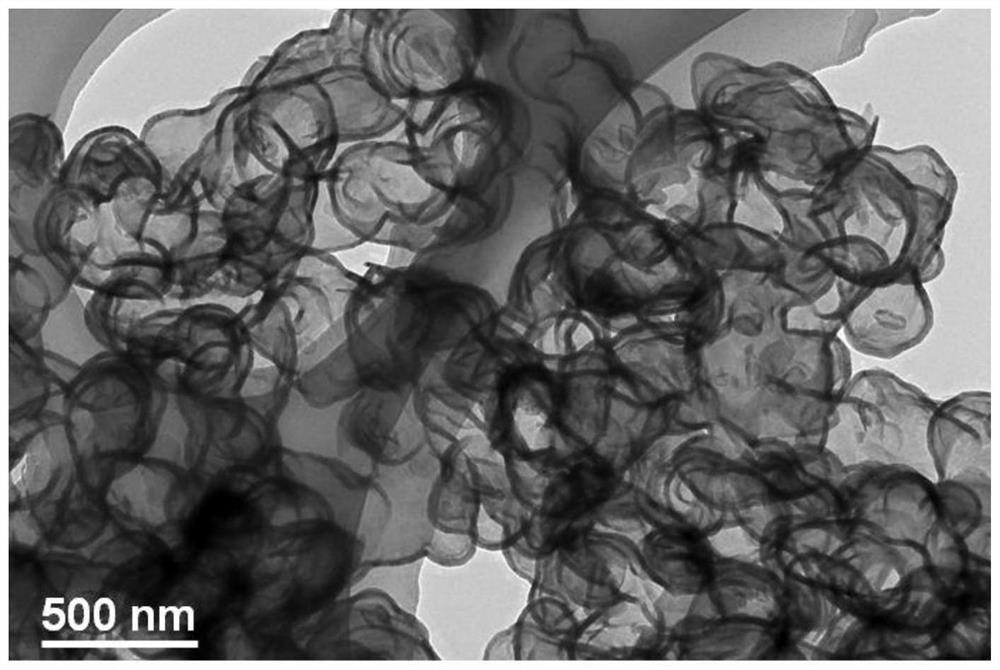

[0032] figure 1 It is the t...

Embodiment 2

[0034] Referring to Example 1, the difference is that the volume fraction of N,N-diethylacetamide in the mixed aqueous solution is 0.1%, placed in an oven and heated to 180°C, reacted for 10h, and transferred the supramolecular intermediate to a porcelain crucible Calcined at a high temperature in a muffle furnace at 550°C to obtain a polymeric carbon nitride catalyst PCN-N 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com