Production process, product and equipment of additive-free red oil thick broad-bean sauce

A technology of production equipment and production process, applied in the production process and equipment field of zero-added red oil bean paste, can solve the problems of inability to stir the bean paste, and achieve the effects of high degree of automation, outstanding appearance and delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

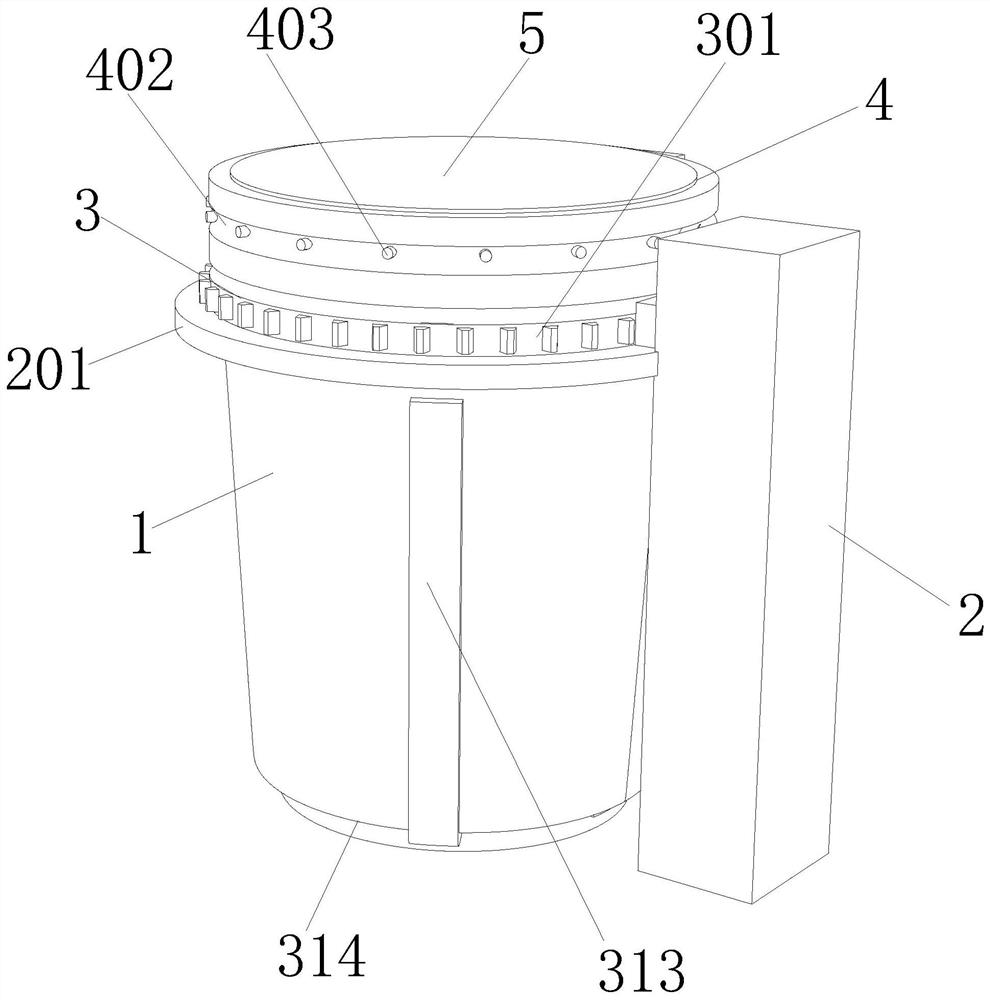

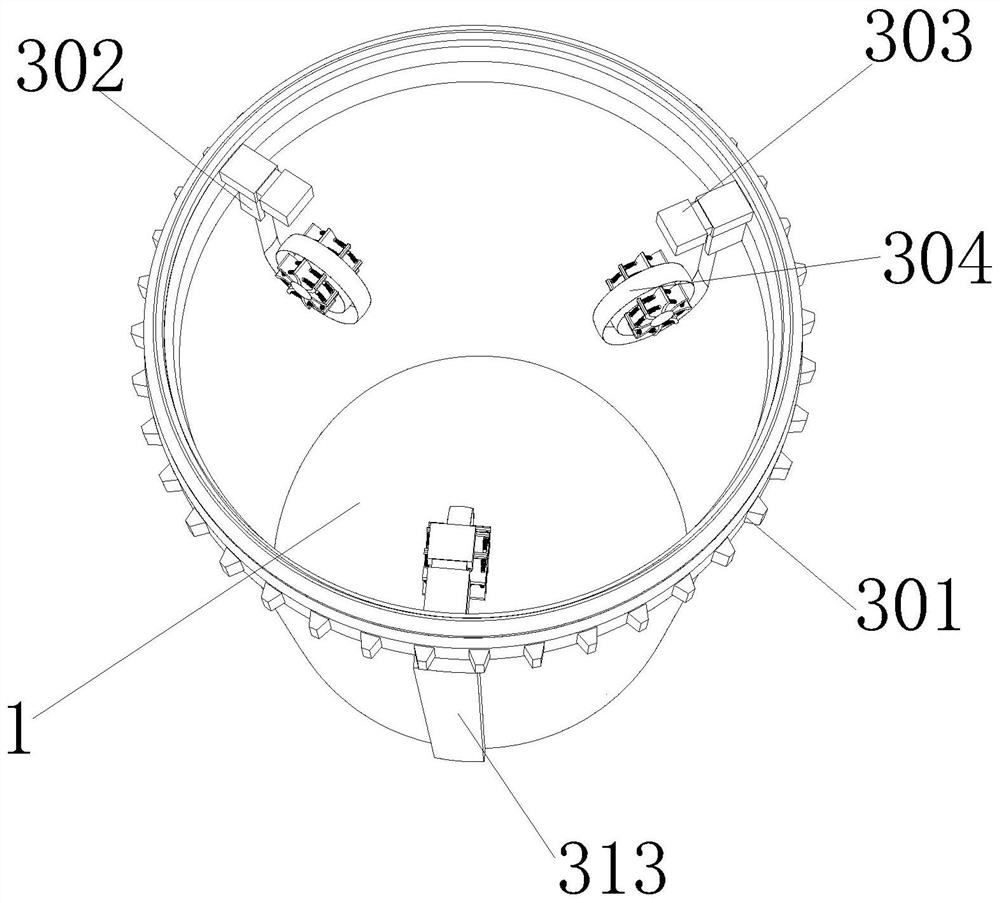

Image

Examples

Embodiment 1

[0055] A kind of production technology of zero-added red oil bean paste, comprises the following steps:

[0056] 1) Material selection: use thin-skinned red peppers and broad beans as raw materials, screen out the defective products such as insect eyes and deterioration in the broad beans, peel them into broad bean valves, and select the defective products such as corruption and deterioration in the red peppers, and after the sorting is passed , broad bean watercress and red pepper are prepared for use according to the mass ratio of 4:5;

[0057] 2) Fermentation pretreatment of broad beans: scald broad bean flaps with water at 80-100°C for 40 seconds, then soak them in warm water at about 30°C for about 5 minutes. It is advisable not to drip water, and it is weighed based on the weight of broad bean splits before soaking koji essence, and 10% flour based on the weight of the broad bean split before soaking, after the koji essence and the flour are stirred and mixed evenly, t...

Embodiment 2

[0067] A kind of production technology of zero-added red oil bean paste, comprises the following steps:

[0068] 1) Material selection: use thin-skinned red peppers and broad beans as raw materials, screen out the defective products such as insect eyes and deterioration in the broad beans, peel them into broad bean valves, and select the defective products such as corruption and deterioration in the red peppers, and after the sorting is passed , broad bean watercress and red pepper are prepared for use according to the mass ratio of 1:1;

[0069] 2) Fermentation pretreatment of broad beans: scald broad bean flaps with water at 80-100°C for 35 seconds, then soak them in warm water at about 30°C for about 5 minutes. It is advisable not to drip water, and it is weighed based on the weight of broad bean splits before soaking koji essence, and 12% flour by weight before soaking the broad bean splits, after stirring the koji essence and the flour evenly, and then evenly mixing the...

Embodiment 3

[0077] A kind of production technology of zero-added red oil bean paste, comprises the following steps:

[0078] 1) Material selection: use thin-skinned red peppers and broad beans as raw materials, screen out the defective products such as insect eyes and deterioration in the broad beans, peel them into broad bean valves, and select the defective products such as corruption and deterioration in the red peppers, and after the sorting is passed , broad bean watercress and red pepper are prepared for use according to the mass ratio of 1:2;

[0079] 2) Fermentation pretreatment of broad beans: scald broad bean flaps with water at 80-100°C for 45 seconds, then soak them in warm water at about 30°C for about 5 minutes. It is advisable not to drip water, and it is weighed based on the weight of broad bean splits before soaking koji essence, and 8% flour by weight before soaking the broad bean splits, after stirring the koji essence and the flour evenly, and then evenly mixing them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com