Flexible lithium battery piece of composite solid electrolyte and preparation method of flexible lithium battery piece

A solid-state electrolyte and lithium battery technology, applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve problems such as polluting the environment, complicated processes, and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

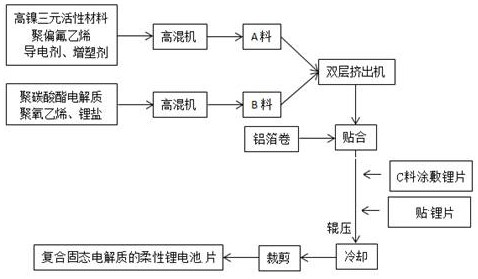

Method used

Image

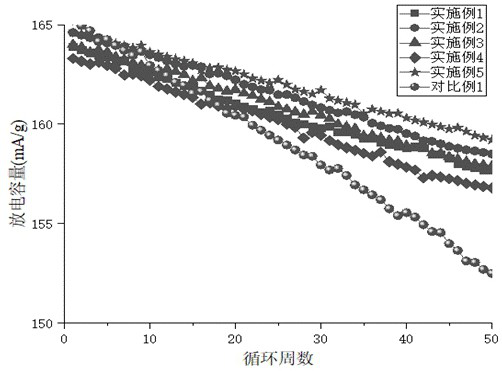

Examples

Embodiment 1

[0044] (1) In parts by weight, add 76 parts by weight of 622-type nickel-cobalt lithium manganate ternary active material, 13 parts by weight of polyvinylidene fluoride, 2.6 parts by weight of acetylene black and 2.2 parts by weight of dimethyl sulfoxide into a high-speed mixer , dispersed evenly to obtain material A;

[0045] (2) In parts by weight, 100 parts by weight of polyethylene carbonate, 17 parts by weight of polyethylene oxide, and 70 parts by weight of lithium bistrifluoromethanesulfonimide were added to the high mixer, and dispersed evenly to obtain material B;

[0046] (3) In parts by weight, mix 5 parts by weight of polyethylene glycol-polyglyceryl methacrylate block copolymer gel and 1.6 parts by weight of lithium bistrifluoromethanesulfonimide, and disperse evenly to obtain C material;

[0047] (4) Add material A obtained in step (1) and material B obtained in step (2) respectively into the material A extruder and material B extruder of the double-layer co-ext...

Embodiment 2

[0049] (1) In parts by weight, add 78 parts by weight of 622-type nickel-cobalt lithium manganate ternary active material, 15 parts by weight of polyvinylidene fluoride, 2.5 parts by weight of acetylene black, and 2.2 parts by weight of dimethyl sulfoxide into the high-speed mixer In the middle, the dispersion is uniform, and the material A is obtained;

[0050] (2) In parts by weight, add 100 parts by weight of polypropylene carbonate, 15 parts by weight of polyethylene oxide, and 60 parts by weight of lithium bistrifluoromethanesulfonimide into a high-mixer, disperse evenly, and obtain material B;

[0051] (3) In parts by weight, mix 3 parts by weight of polyethylene glycol-polyglyceryl methacrylate block copolymer gel and 1.0 parts by weight of lithium bistrifluoromethanesulfonimide, and disperse evenly to obtain C material;

[0052] (4) Add material A obtained in step (1) and material B obtained in step (2) respectively into the material A extruder and material B extruder...

Embodiment 3

[0054] (1) In parts by weight, add 80 parts by weight of 622-type nickel-cobalt lithium manganate ternary active material, 15 parts by weight of polyvinylidene fluoride, 3.0 parts by weight of acetylene black, and 2.0 parts by weight of dimethyl sulfoxide into the high-speed mixer In the middle, the dispersion is uniform, and the material A is obtained;

[0055] (2) In parts by weight, 100 parts by weight of polyvinyl carbonate, 15 parts by weight of polyethylene oxide, and 60 parts by weight of lithium bistrifluoromethanesulfonimide were added to the high mixer, and dispersed evenly to obtain material B;

[0056] (3) In parts by weight, mix 5 parts by weight of polyethylene glycol-polyglyceryl methacrylate block copolymer gel and 2.0 parts by weight of lithium bistrifluoromethanesulfonimide, and disperse evenly to obtain C material;

[0057] (4) Add material A obtained in step (1) and material B obtained in step (2) respectively into the material A extruder and material B ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com