Method for preparing hotpot condiment grease rich in medium and long carbon chain triglyceride by enzyme method

A technology for triglyceride and enzymatic preparation, applied in the direction of fermentation, etc., can solve the problem of not meeting the expected properties of hot pot base oil, and achieve the effects of shortening synthesis time, reducing cancer risk, and weakening protein metabolism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

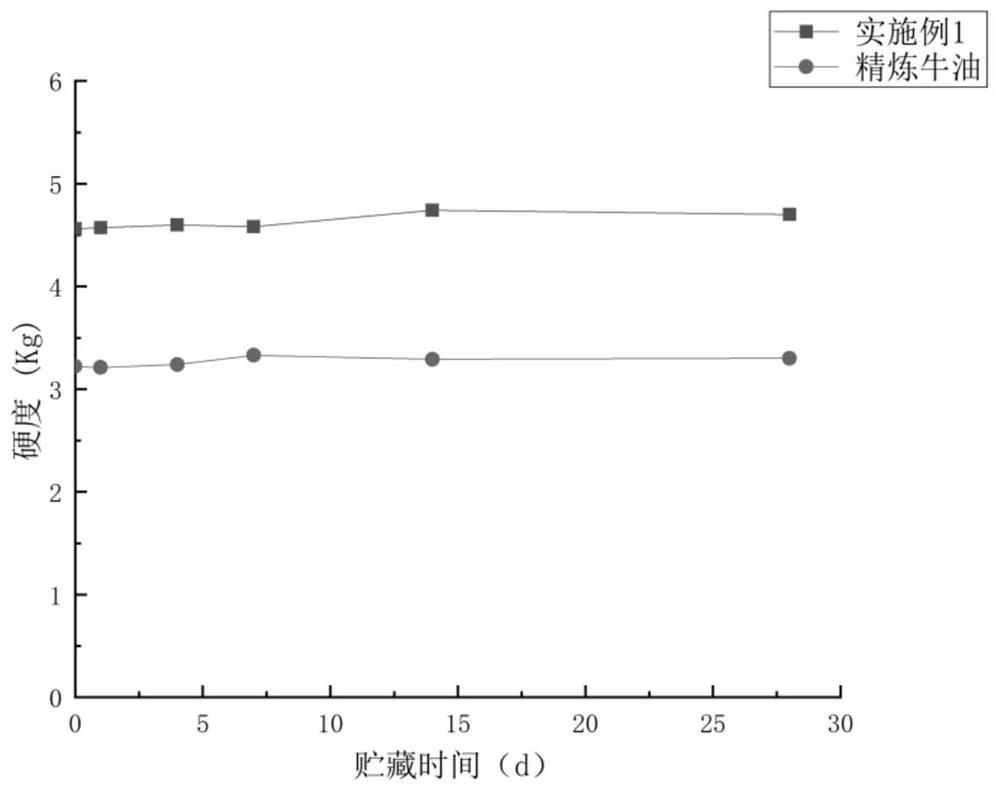

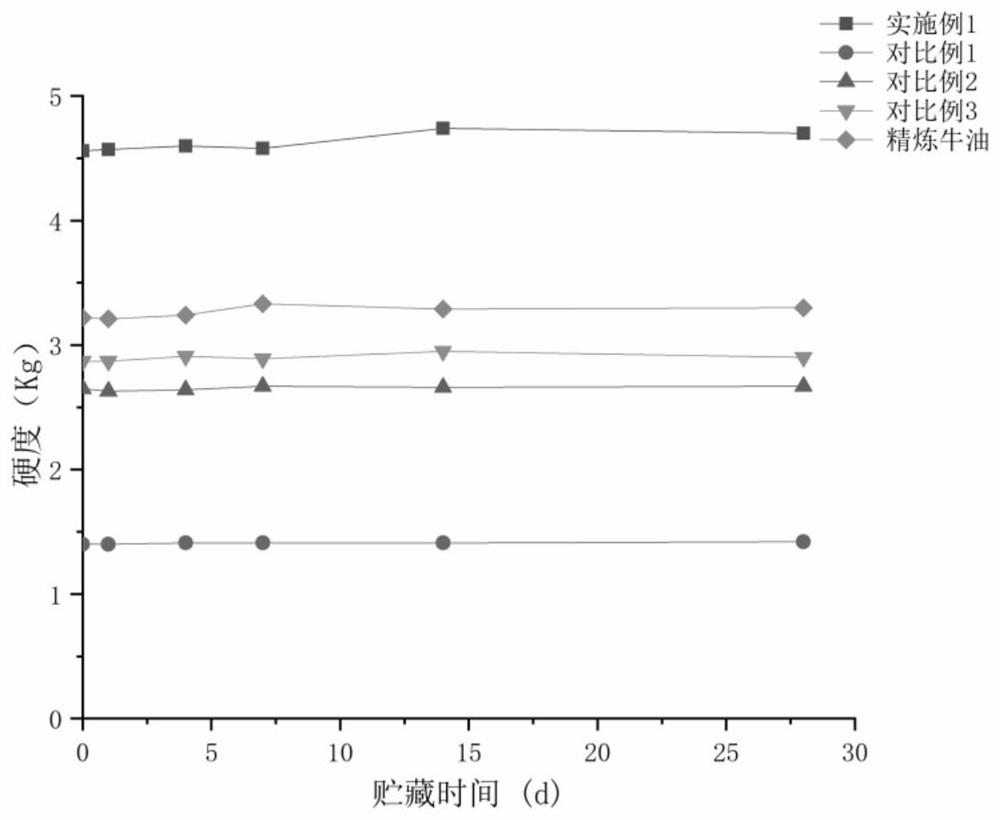

Embodiment 1

[0034] Vegetable oil raw material type and ratio formula are as follows:

[0035]

[0036] The immobilized enzyme NS40086 (purchased from Novozymes (China) Biotechnology Co., Ltd., with an enzyme activity of 275 IUN / g) was pre-swelled in the reaction substrate at 65° C. for 15 hours.

[0037] Batch enzyme reactions are carried out in batch stirred tank reactors.

[0038] Under the solvent system, the volume mass ratio of n-hexane to the substrate is 3:1, the mass ratio of coconut oil: soybean oil: palm stearin is 3:2:5, and the immobilized enzyme NS40086 accounting for 5% of the mass ratio of the substrate is added , Stir the reaction at 70°C under normal pressure for 4h.

[0039] After the reaction, the reaction product was removed by rotary evaporation to remove n-hexane, and the immobilized enzyme was removed by centrifugal sedimentation. The sample was removed by KOH-hydroalcoholic solution to remove free fatty acid. The analysis results of the obtained product are sho...

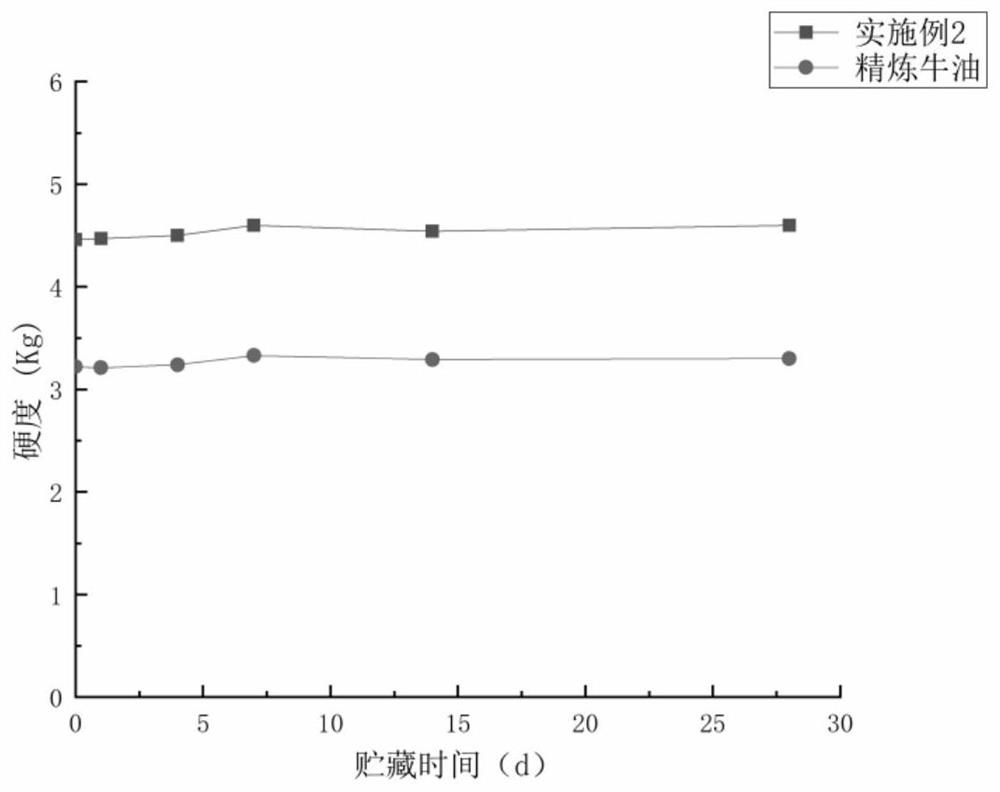

Embodiment 2

[0072] Vegetable oil raw material type and ratio formula are as follows:

[0073]

[0074] The immobilized enzyme NS40086 (purchased from Novozymes (China) Biotechnology Co., Ltd., with an enzyme activity of 275 IUN / g) was pre-swelled in the reaction substrate at 65° C. for 15 hours.

[0075] Batch enzyme reactions are carried out in batch stirred tank reactors.

[0076] Under the solvent system, the volume mass ratio of n-hexane to the substrate is 3:1, the mass ratio of coconut oil: soybean oil: palm stearin is 6:5:9, and the immobilized enzyme NS40086 accounting for 5% of the mass ratio of the substrate is added , Stir the reaction at 70°C under normal pressure for 4h.

[0077] After the reaction, the reaction product was removed by rotary evaporation to remove n-hexane, and the immobilized enzyme was removed by centrifugal sedimentation. The sample was removed by KOH-hydroalcoholic solution to remove free fatty acid. The analysis results of the obtained product are sho...

Embodiment 3

[0116] Vegetable oil raw material type and ratio formula are as follows:

[0117]

[0118] The immobilized enzyme Lipozyme TL IM (purchased from Novozymes (China) Biotechnology Co., Ltd., with an enzyme activity of 250 IUN / g) was pre-swelled in the reaction substrate at 65°C for 15h.

[0119] Batch enzyme reactions are carried out in batch stirred tank reactors.

[0120] Under the solvent system, the volume mass ratio of n-hexane to the substrate is 3:1, the mass ratio of coconut oil: soybean oil: palm stearin is 6:5:9, and the immobilized enzyme Lipozyme accounting for 5% of the mass ratio of the substrate is added TL IM, stirred at 65°C for 3h under normal pressure.

[0121] After the reaction, the reaction product was removed by rotary evaporation to remove n-hexane, and the immobilized enzyme was removed by centrifugal sedimentation. The sample was removed by KOH-hydroalcoholic solution to remove free fatty acid. The analysis results of the obtained product are shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com