Nano rare earth oxide modified functional coating and preparation method thereof

A nano-rare earth and oxide technology, applied in epoxy resin coatings, chemical instruments and methods, manganese compounds, etc., can solve the problems of poor coating dispersion, single function, and a large number of micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0029] The nano-rare earth oxide modified functional coating of the present invention comprises the following components in parts by weight: 1-3 parts of nano-rare earth lanthanum strontium manganese oxide, 10-20 parts of ethanol aqueous solution, 0.5-3 parts of silane coupling agent, 50-70 parts of epoxy resin, 30-50 parts of diluent, 0.3-3 parts of modified potassium magnesium titanate, 50-90 parts of bio-based curing agent and 0.05-0.1 part of auxiliary agent.

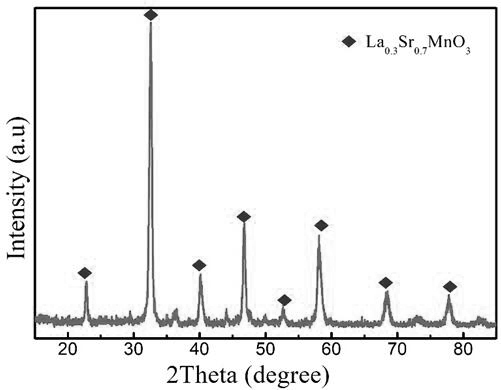

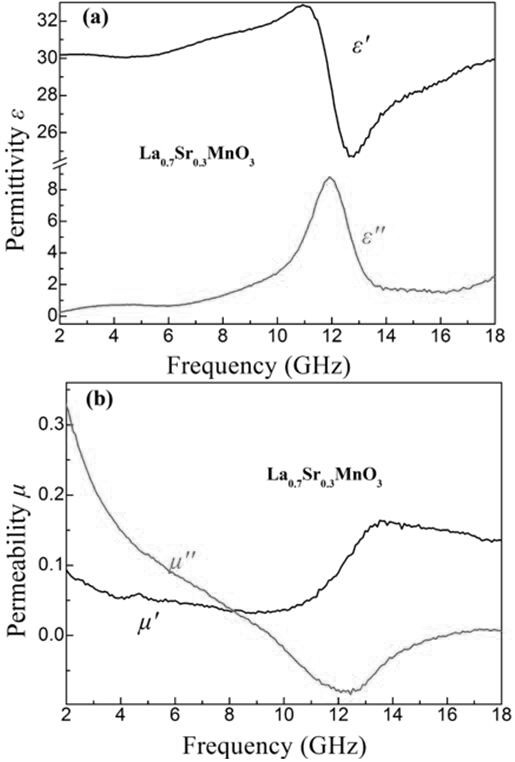

[0030] The molecular formula of nanometer rare earth lanthanum strontium manganese oxide is La 1-x Sr x MnO 3 , where 0.1≤x≤0.7, the lanthanum nitrate La(NO 3 ) 3 , strontium acetate Sr(C 2 h 3 o 2 ) 2 , the mass ratio of the mixed solvent, glacial acetic acid and ethanolamine is (10-30): (2-15): (60-80): (10-20): (10-20), including the following specific preparation st...

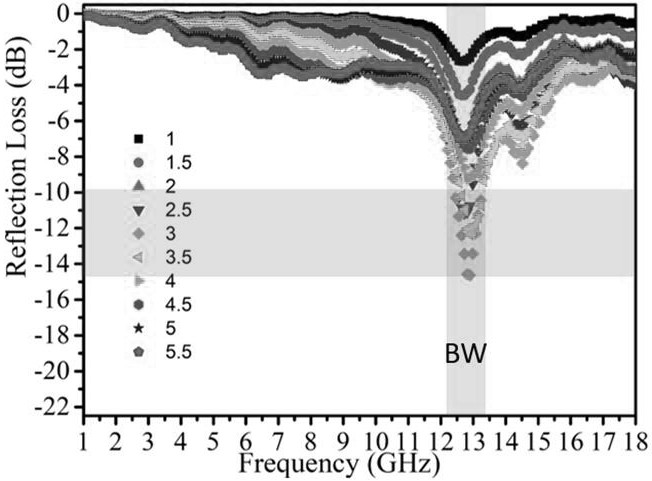

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com