Recovery system and recovery method for gas-phase benzene in caprolactam

A caprolactam and recovery system technology, applied in the field of benzene recovery, can solve the problems of increasing benzene consumption and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

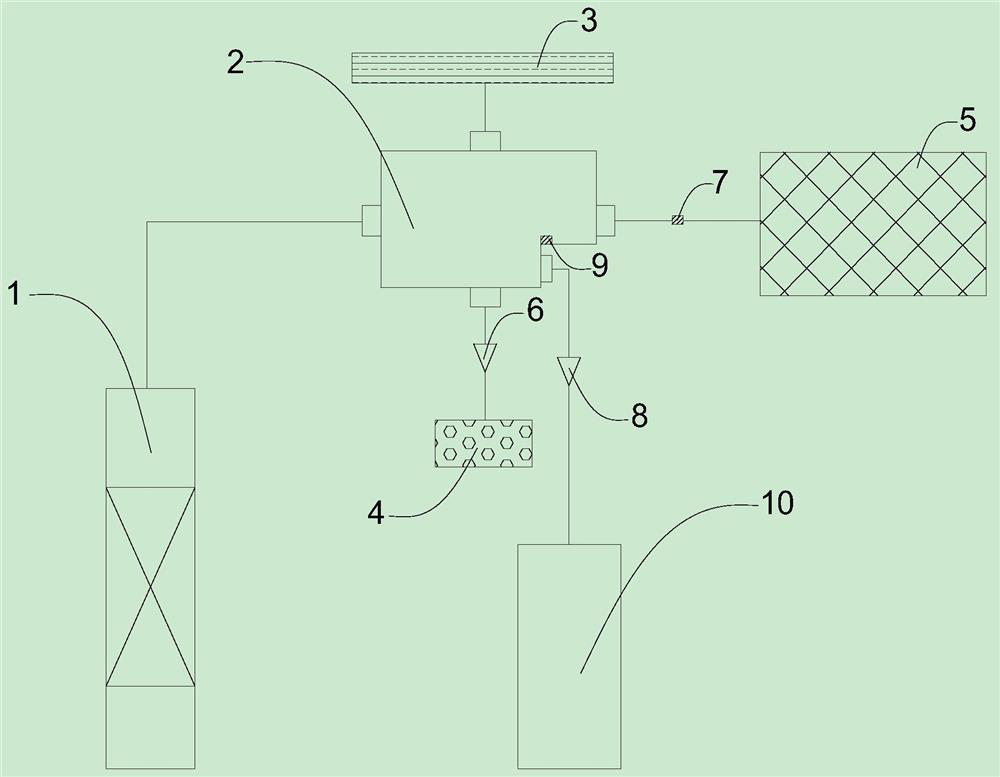

[0029] Please refer to figure 1 , figure 1 Shown is the cross-sectional structure diagram of the system in the embodiment of the present invention.

[0030] This embodiment provides a recovery system for benzene in caprolactam, which includes an extraction device and a vaporization condensation separator 2, and the extraction device and the vaporization condensation separator 2 are in fluid communication. The recovery system of benzene in caprolactam also includes a benzene pump tank 10, which is in fluid communication with the vaporization condensation separator 2, and a first valve 6 is arranged between the gasification condensation separator 2 and the benzene pump tank 10. In this embodiment, the gaseous benzene in the caprolactam benzene solution after extraction is condensed and liquefied by setting the vaporization condensation separator 2 and the extraction device. In this embodiment, the extraction device is a water extraction tower 1, wherein the water extraction tow...

Embodiment 2

[0035] Please refer to figure 1 , figure 1 Shown is the cross-sectional structure diagram of the system in the embodiment of the present invention. This embodiment provides a recovery method based on the gas-phase benzene recovery system in caprolactam, comprising the following steps: passing the mixed solution of caprolactam and benzene into the water extraction tower 1, keeping the internal temperature of the water extraction tower 1 at 40°C, and The air pressure is 0 MPa, and extracted with water to obtain an aqueous solution of benzene and caprolactam. The gas released from the top of the water extraction tower 1 enters the vaporization condensation separator 2 and passes into the liquid nitrogen in the liquid nitrogen tank 4 for heat exchange and condensation, and the discharged non-condensable gas In the tail gas removal treatment device 5, when the reading of the temperature controller 7 is 7°C, the opening of the second valve 6 remains unchanged to maintain the stable...

Embodiment 3

[0037] Please refer to figure 1 , figure 1 Shown is the cross-sectional structure diagram of the system in the embodiment of the present invention. This embodiment provides a recovery method based on the gas-phase benzene recovery system in caprolactam, comprising the following steps: passing the mixed solution of caprolactam and benzene into the water extraction tower 1, keeping the internal temperature of the water extraction tower 1 at 45°C, and The air pressure is 0.01MPa, extracted with water to obtain an aqueous solution of benzene and caprolactam, the gas released from the top of the water extraction tower 1 enters the vaporization condensation separator 2 and passes into the liquid nitrogen in the liquid nitrogen tank 4 for heat exchange and condensation, and the discharged non-condensable In the gas de-tail gas treatment device 5, when the reading of the temperature controller 7 is 10°C, the opening of the second valve 6 remains unchanged to maintain the stable deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com