Mask-free preparation method of copper electrode of heterojunction solar cell

A technology of heterojunction cells and solar cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of many consumables, complex processes, complex processes, etc., to achieve good uniformity, reduce interface contact resistance, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

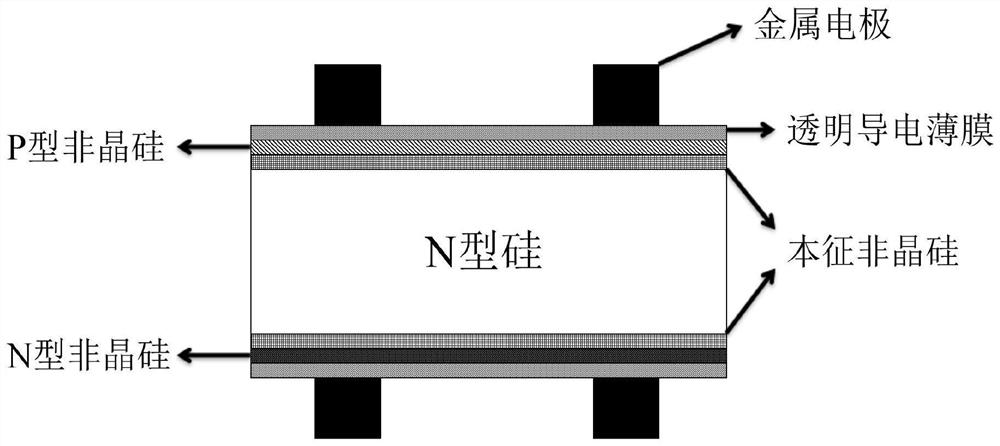

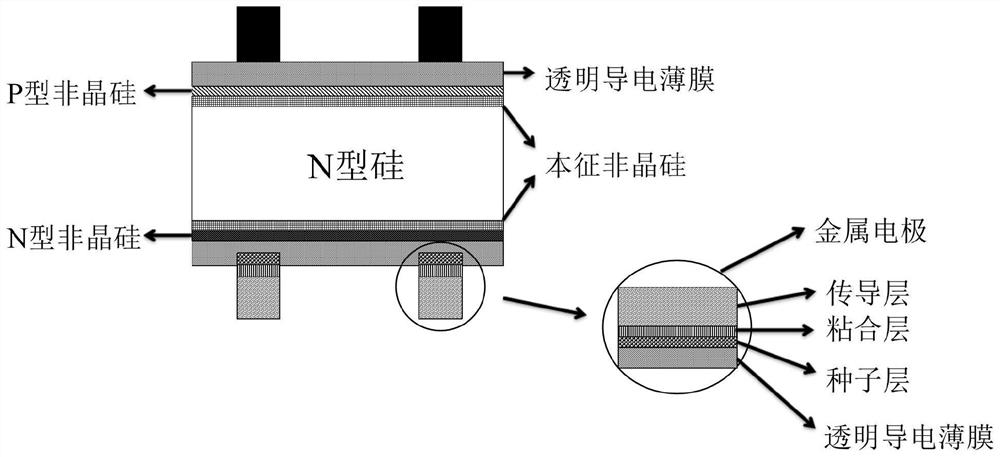

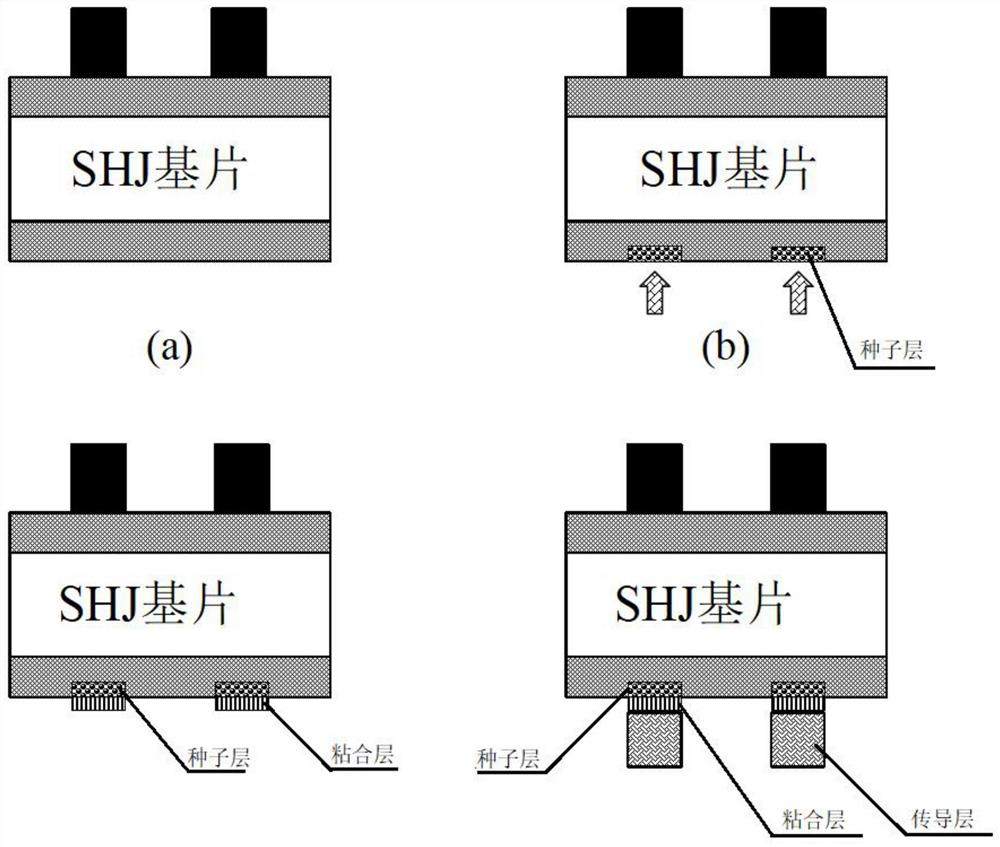

[0022] Such as figure 1 As shown, the present invention is a maskless preparation method of a copper electrode of a heterojunction solar cell. The copper electrode of a heterojunction solar cell includes a transparent conductive film and an N-type doped layer deposited on a substrate of a heterojunction solar cell. The metal electrode of side electroplating, described metal electrode comprises metal seed layer, metal adhesion layer and metal conduction layer, and described preparation method comprises the following steps:

[0023] Prepare the heterojunction battery substrate, and deposit transparent conductive films on both sides of the heterojunction battery substrate, and prepare metal grid lines on the P side of the battery substrate;

[0024] The N side of the heterojunction battery substrate is immersed in the solution as the negative electrode, and the P side metal g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com