Method for rapidly screening corrosion inhibitor under high-salinity water condition

A technology with high salinity and screening method, applied in the direction of electrochemical variables of materials, etc., can solve the problems such as no screening and evaluation method of corrosion inhibitor, limited application range, inability to meet the complexity of actual working conditions, etc., and achieve rapid screening and delay. Corrosion, excellent protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: Compatibility evaluation is carried out to the corrosion inhibitor to be adopted:

[0055] The screening process provided in this embodiment can efficiently and quickly screen out corrosion inhibitors that meet the on-site anti-corrosion requirements.

[0056] The specific screening steps are as follows:

[0057] Step 1: Collect the corrosion condition parameters of pipelines in the oilfield production and transportation system: chloride ion content 123000mg / L, CO 2 Partial pressure 0.25MPa, H 2 S partial pressure is 0.0132MPa, gathering temperature is 50℃, flow velocity is 1.0m / s, the phase distribution in the gathering pipeline is gas phase, gas-liquid interface and liquid phase distribution, and the oil-water ratio is 3:2;

[0058] Step 2: According to the parameters of oil field corrosion conditions, the 10 kinds of corrosion inhibitors collected in accordance with the corrosion conditions are sequentially numbered as No. 1-10;

[0059] Step 3: Eval...

Embodiment 2

[0063] Example 2: Using electrochemical corrosion to detect point defect concentration

[0064] Step 4: Use the electrochemical corrosion detection method to evaluate the corrosion inhibitor with good compatibility in step (3), and screen out the corrosion inhibitor resistant to pitting corrosion. The experimental steps are as follows:

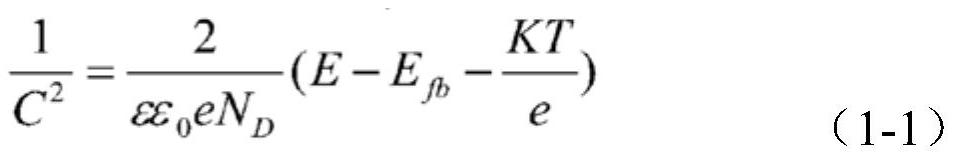

[0065] a. Test and calculation of point defect concentration: connect the cleaned, polished and passivated pipeline steel sample (50×25×2mm) to the electrode, and immerse it in the medium solution of the simulated gathering and transportation system for 30 minutes to obtain a stable open circuit potential; The chemical workstation measures the change of passive film impedance with the potential, the scanning range is -0.1~0.6V, the potential increment is 0.01V, and the frequency is 1000Hz; calculate the point defect concentration of the passive film: draw the Mott-Schottky curve, according to the formula (1-1), calculate the point defect conce...

Embodiment 3

[0068] Embodiment 3: pitting probability test

[0069] b. Pitting probability test: Divide the pipeline steel sample in step a into 25 areas. Tested on a large-scale scanning Kelvin probe system test platform, the distance between the probe and the sample surface is controlled at 100 μm. The frequency of the probe parameters is 80Hz, and the amplitude is 30μm. Select the surface scanning mode to scan any area according to the principle of "from bottom to top, from left to right". Taking the midpoint of the area as the center, the length and width of the scanning area are 2mm and 1mm respectively, and the scanning step is selected as 200μm. After the test, a three-dimensional map of the potential distribution is obtained. If the difference between the lowest potential of the area and the highest potential of the area is greater than 200mV, it is determined that the area will be When pitting occurs, record the number of regions where pitting occurs on the test steel sheet as m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com