Smelting technology of alloyed high-manganese steel

A high-manganese steel and alloying technology is applied in the metallurgical field of high-manganese steel, which can solve the problems of high cost of alloying high-manganese steel, unstable product quality, and difficulty in ensuring the yield of three alloys, and improve the metallographic structure. , The effect of improving service life and improving mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

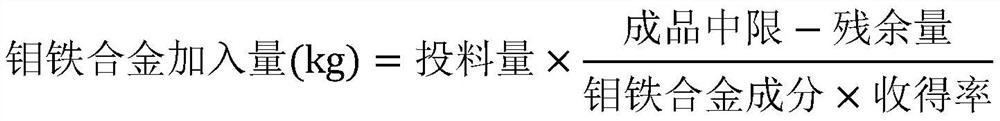

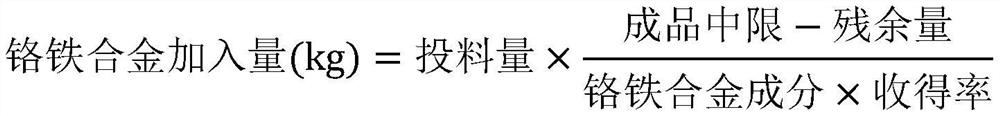

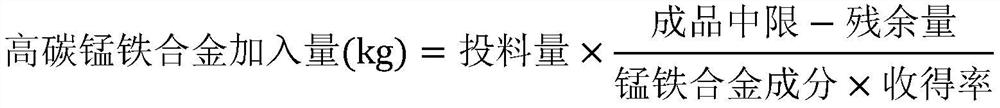

[0022] The embodiment of the present invention provides a smelting process of alloyed high manganese steel, the alloyed high manganese steel is composed of the following chemical components in weight ratio: C: 0.95-1.35%; Mn: 11.0-14.0%; Si: 0.30- 0.80%; Mo: 0.20~1.20%; Cr: 0.20~1.00%; V: 0.05~0.35%; P: ≤0.045%; S: ≤0.030%; Specifically include the following steps:

[0023] Step 1: Put ordinary steel scrap raw materials and ferromolybdenum alloy into the electric arc furnace to form a furnace charge, and spread the ferromolybdenum alloy evenly around the electrodes of the electric arc furnace.

[0024] Check the furnace body, furnace cover, water cooling system, air supply system, electrical equipment and mechanical transmission device before feeding, and check whether the residual steel residue i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com