A kind of self-doped nitrogen-supported palladium porous composite structure oxygen reduction catalyst and its preparation method and application

A composite structure and catalyst technology, applied in structural parts, rayon manufacturing, electrochemical generators, etc., can solve the problems of increased process difficulty, low adsorption capacity, low specific surface area, etc., to reduce production costs, improve activity, and reduce production costs. The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

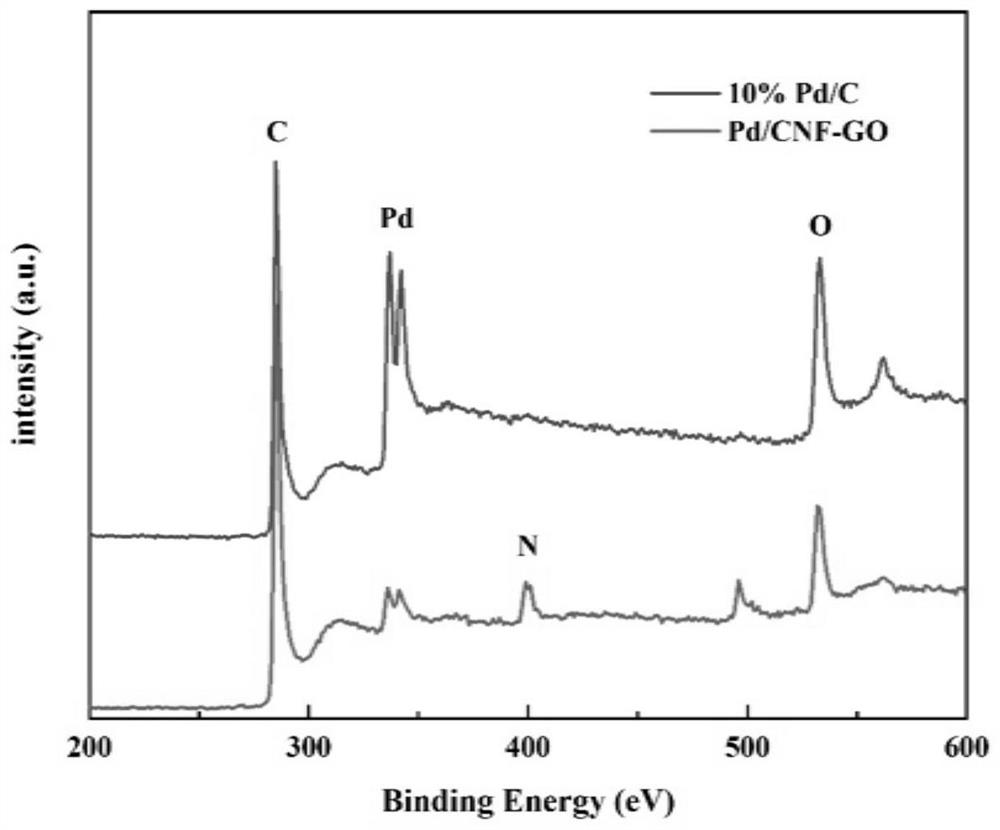

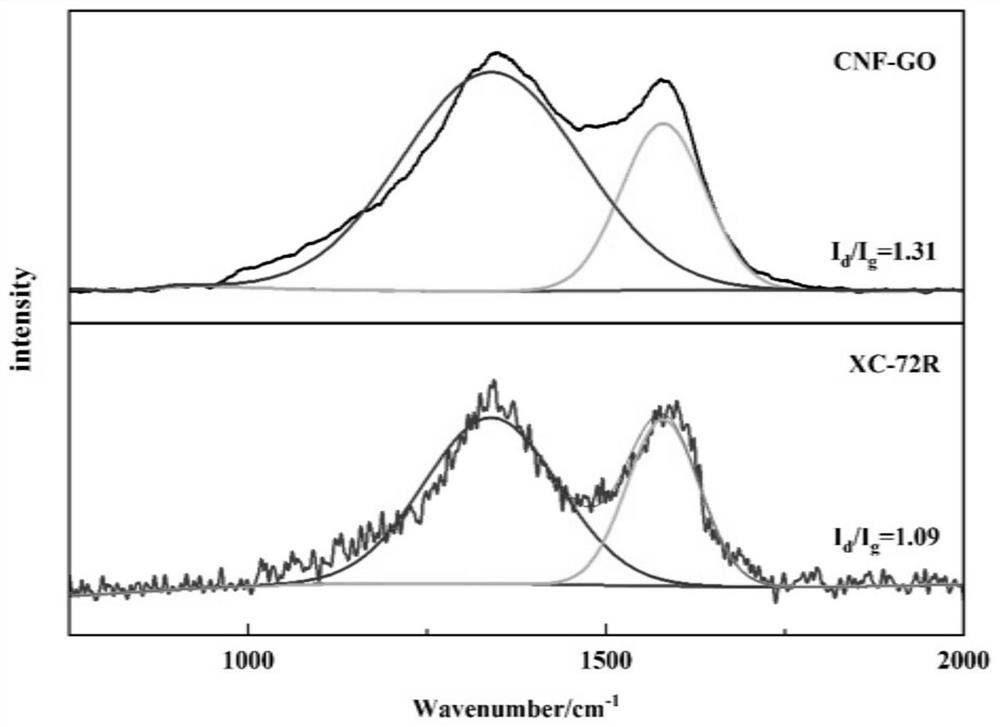

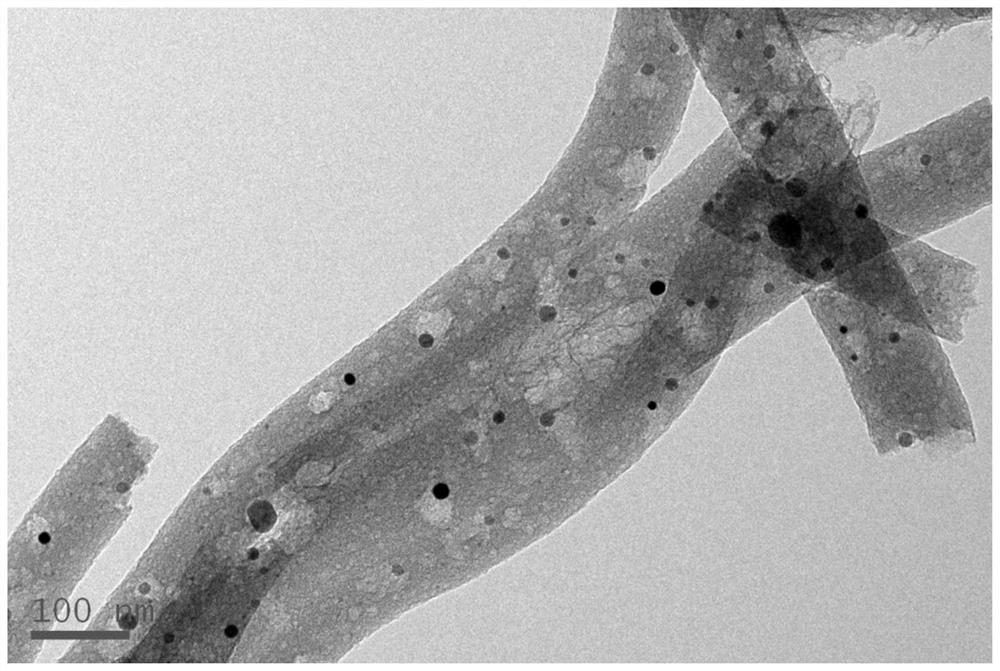

[0041] Weigh 200mg NaPdCl 4 , 100 mg of GO, 1 g of PVP and 1 g of PAN were dissolved in 10 g of DMF solvent, uniformly stirred to completely dissolve, and the electrospinning precursor solution was obtained. Load the precursor solution into a 10ml syringe, select a needle with an inner diameter of 0.5±0.02mm, load the syringe into the electrospinning machine, set the distance between the drum and the needle to 16cm, the drum speed to 500rpm / min, and the syringe advance speed to 0.3ml / h , Voltage 20kV. After the spinning is completed, the raw yarn obtained by spinning is put into a tube furnace, pre-oxidized in an air atmosphere of 280 °C for 2 hours, carbonized in a nitrogen atmosphere of 800 °C for 2 hours, and then heated at 200 °C N 2 / H 2 (flow rate ratio 3:1) was reduced in the atmosphere for 2 h to obtain a Pd / CNF-GO catalyst. Take 4 mg of the prepared Pd / CNF-GO catalyst and disperse it in 0.5 ml of nafion aqueous solution (0.05%). After sonicating for 30 min, take 10...

Embodiment 2

[0050] Weigh 200mg K 2 PdCl 6 , 100 mg of GO, 1 g of PVP and 1 g of PAN were dissolved in 10 g of DMF solvent, uniformly stirred to completely dissolve, and the electrospinning precursor solution was obtained. Load the precursor solution into a 10ml syringe, select a needle with an inner diameter of 0.4±0.02mm, load the syringe into the electrospinning machine, set the distance between the drum and the needle to 12cm, the drum rotation speed to 500rpm / min, and the injection speed of the syringe to 0.2ml / h , Voltage 16kV. After the spinning is completed, the raw yarn obtained by spinning is put into a tube furnace, pre-oxidized in an air atmosphere at 260 °C for 2 hours, carbonized in a nitrogen atmosphere at 800 °C for 2 hours, and then heated at 200 °C N 2 / H 2 (flow rate ratio 3:1) was reduced in the atmosphere for 2 h to obtain a Pd / CNF-GO catalyst. Take 4 mg of the prepared Pd / CNF-GO catalyst and disperse it in 0.5 ml of nafion aqueous solution (0.05%). After sonicatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com