A Helium Microcirculation Refrigerated Dewar System for Superconducting Magnets

A technology of superconducting magnets and Dewars, applied in superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problems of icing on the low-temperature end wall of the container, lack of helium recovery conditions, and affecting heat conduction efficiency. The effect of reducing the chance of freezing, ensuring the efficiency of heat conduction, and being friendly to the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

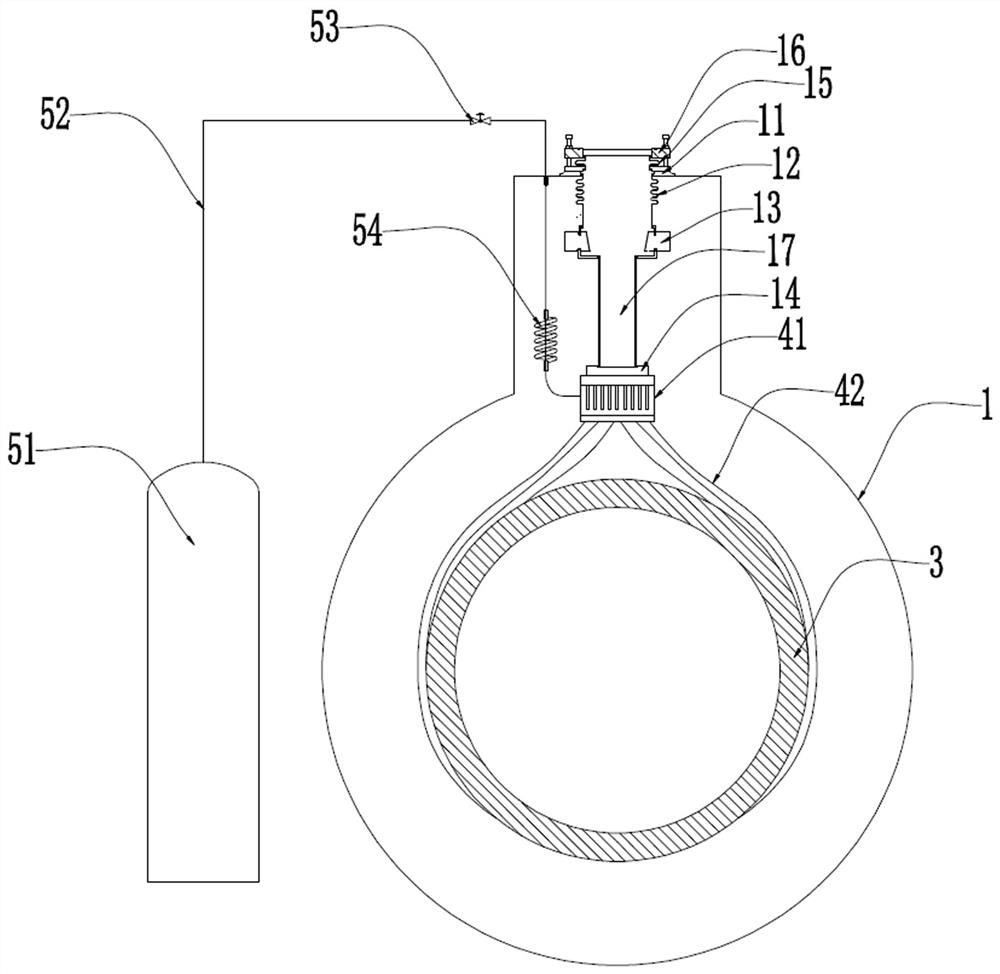

[0032] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

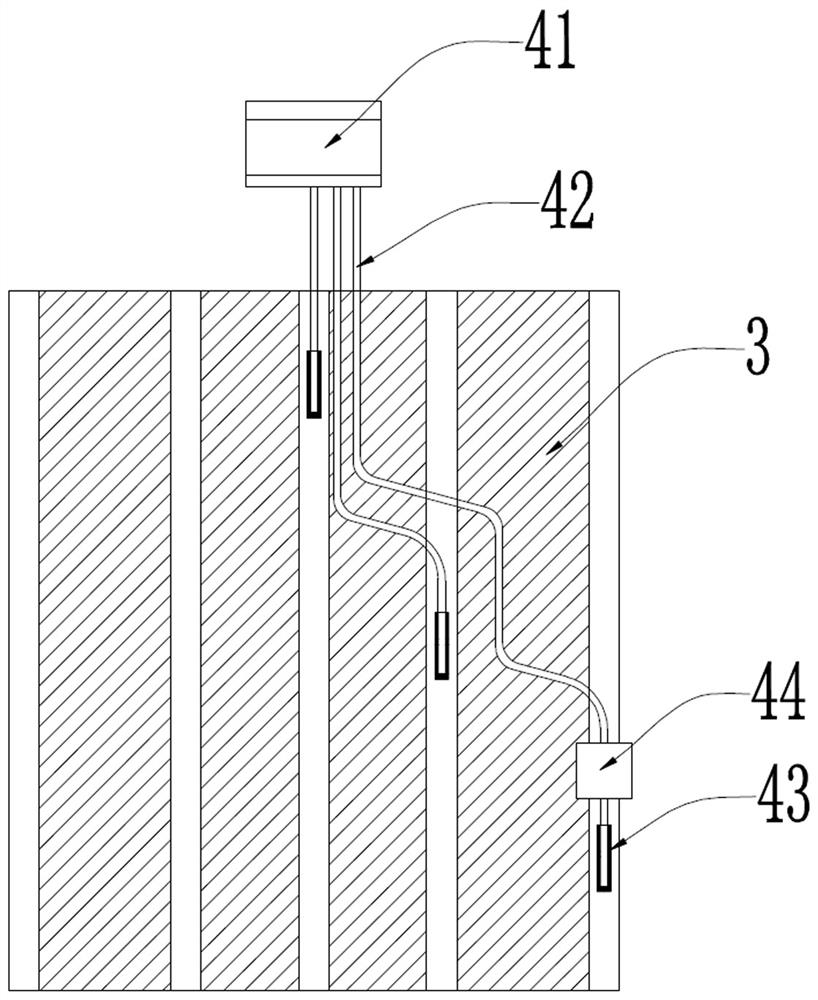

[0033] Please refer to Figure 1-Figure 3 , an embodiment of a helium microcirculation refrigeration Dewar system for a superconducting magnet provided by the present invention, comprising:

[0034] Dewar 1, Dewar 1 is used to form a sealed chamber containing superconducting coil 3; the outer surface of Dewar 1 has a concave heat conduction cavity 17, and the cold head of the refrigerator can extend into the heat conduction cavity 17;

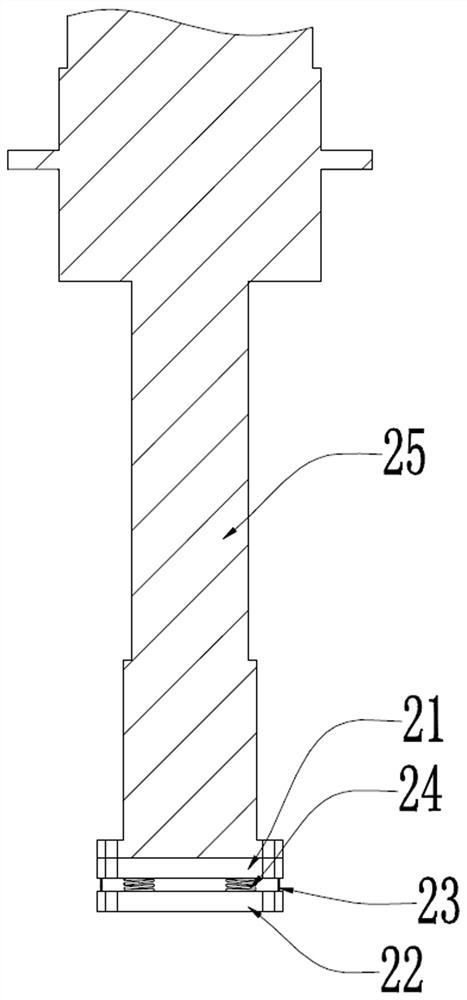

[0035] Coupling head, the coupling head extends into the heat conduction cavity 17, and the end face of one end of the coupling head is connected with the inner bottom wall of the heat conduction cavity 17, and the coupling head is used to connect the cold head of the refrigerator with the inner bottom wall of the heat conduction cavity 17, thereby connecting the refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com