Silicon carbide nano heat-insulating and wave-absorbing composite material and preparation method thereof

A silicon carbide nanowire and nano thermal insulation technology, which is applied in the fields of carbon compounds, chemical instruments and methods, carbon preparation/purification, etc. , failure to achieve the expected goals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

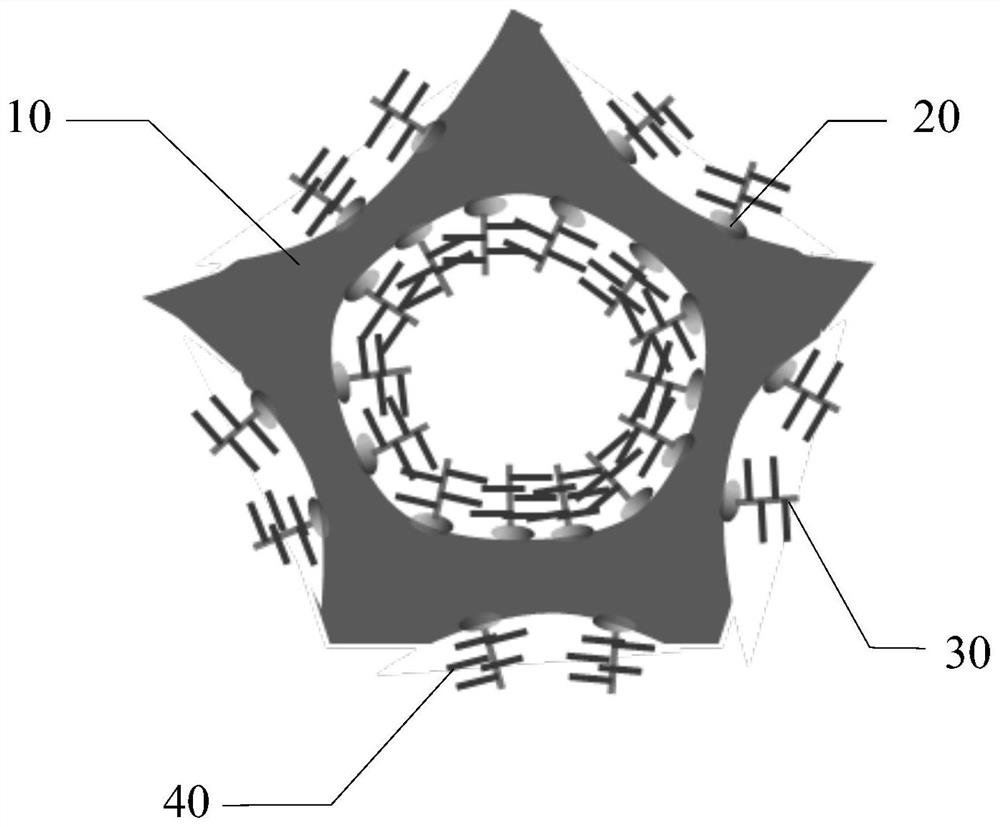

[0024] refer to figure 1 , is a schematic diagram of the structure of a silicon carbide nano heat-insulating and wave-absorbing composite material, 10 is the carbon foam substrate template, 20 is the SiC coating reinforced interface, 30 is the initial SiC nanowire, 40 is the secondary SiC nanowire, the volume The density is 20.0kg / m 3 , the thermal conductivity at room temperature is 0.032W / (m K), the minimum reflection loss is -38.0dB, the carbon foam base template is a three-dimensional open-pore structure, the compression modulus is 250.0kPa, and the absorption capacity is 7.8kJ / m 3 , the porosity is 96.0%, the cell size is 30.0μm; the silicon carbide coating reinforced interface is discontinuously distributed on the surface of the carbon foam substrate skeleton, the thickness is 1.5μm, the compressive strength is 1.2Mpa, and the compression modulus is 12.0MPa ; The SiC nanowire network structure grows in a dendritic bifurcation at the SiC coating reinforcement interface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com