Wear-resistant tire tread formula

A tread and formula technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of poor wear resistance and heat resistance of the tread, and achieve improved wear resistance and excellent heat resistance , Improve the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

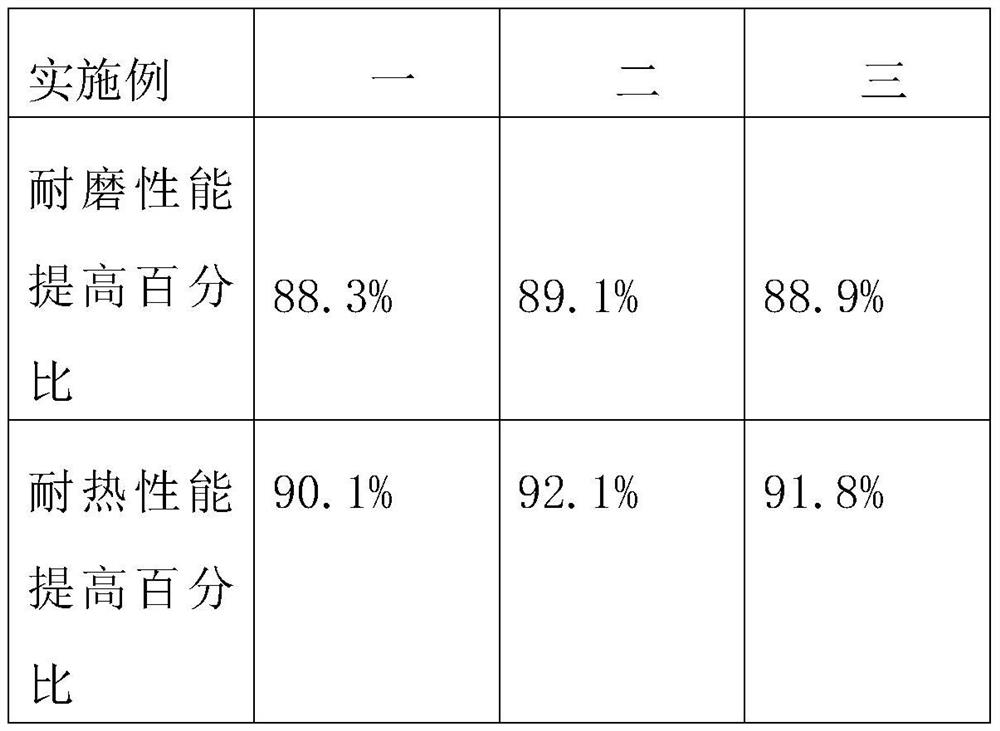

Examples

Embodiment 1

[0030] The invention proposes a wear-resistant tread formula, including the following raw materials in parts by weight: 40 parts of rubber, 1 part of anti-aging agent, 10 parts of carbon black, 5 parts of sulfur, 10 parts of nano-zinc oxide, 1 part of stearic acid, 1 part of magnesium hydroxide, 1 part of aluminum hydroxide, 3 parts of n-phenylmaleimide, 5 parts of calcium stearate, 1 part of phenyl silicone oil;

[0031] Its preparation method comprises the following steps:

[0032] S1: Mix rubber, sulfur, nano zinc oxide, stearic acid, magnesium hydroxide, aluminum hydroxide, n-phenylmaleimide, calcium stearate, and phenyl silicone oil for 1 min. The mixing temperature is 80°C, then add anti-aging agent and carbon black and mix at a mixing temperature of 90°C to make a film;

[0033] S2: The film outlet water is cooled by the cooling water tank. The cooling steps are: first blow the fan to cool, and then carry out natural cooling and air conditioning cooling;

[0034] S3: ...

Embodiment 2

[0036] The invention proposes a wear-resistant tread formula, including the following raw materials in parts by weight: 50 parts of rubber, 34 parts of anti-aging agent, 12 parts of carbon black, 7 parts of sulfur, 12 parts of nano-zinc oxide, 3 parts of stearic acid, 3 parts of magnesium hydroxide, 3 parts of aluminum hydroxide, 5 parts of n-phenylmaleimide, 7 parts of calcium stearate, 3 parts of phenyl silicone oil;

[0037] Its preparation method comprises the following steps:

[0038] S1: Mix rubber, sulfur, nano zinc oxide, stearic acid, magnesium hydroxide, aluminum hydroxide, n-phenylmaleimide, calcium stearate, and phenyl silicone oil for 1.5 minutes , the mixing temperature is 90°C, then adding anti-aging agent and carbon black and mixing, the mixing temperature is 100°C, and the film is obtained;

[0039]S2: The film outlet water is cooled by the cooling water tank. The cooling steps are: first blow the fan to cool, and then carry out natural cooling and air condit...

Embodiment 3

[0042] The present invention proposes a wear-resistant tread formula, including the following raw materials in parts by weight: 60 parts of rubber, 5 parts of anti-aging agent, 15 parts of carbon black, 10 parts of sulfur, and 15 parts of nano-zinc oxide , 5 parts of stearic acid, 5 parts of magnesium hydroxide, 5 parts of aluminum hydroxide, 8 parts of n-phenylmaleimide, 10 parts of calcium stearate, 5 parts of phenyl silicone oil;

[0043] Its preparation method comprises the following steps:

[0044] S1: Mix rubber, sulfur, nano zinc oxide, stearic acid, magnesium hydroxide, aluminum hydroxide, n-phenylmaleimide, calcium stearate, and phenyl silicone oil for 2 minutes. The mixing temperature is 100°C, then adding anti-aging agent and carbon black and mixing, the mixing temperature is 110°C, and the film is obtained;

[0045] S2: The film outlet water is cooled by the cooling water tank. The cooling steps are: first blow the fan to cool, and then carry out natural cooling a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com