Method for preparing cobalt phosphide/carbon composite material by using baker's yeast through impregnation process

A carbon composite material, baker's yeast technology, applied in chemical instruments and methods, catalyst activation/preparation, oxidized water/sewage treatment, etc. Solve toxic or harmful, reduce the effect of metal ion leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 2 g of freeze-dried yeast (which has been activated and immobilized) into the mortar, and then add 0.882 mL of Co(NO 3 ) 2 The solution was loaded with cobalt ions, and after careful grinding, the sample was dried in an oven at 60 °C to obtain a solid powder. Transfer the obtained solid powder to a tube furnace, raise the temperature from room temperature to 800, 900 or 1000 °C at a rate of 5 °C / min under the protection of argon, keep it for 4 h, then cool down to room temperature under the protection of argon, The obtained materials are taken out and ground into powder to obtain composite materials, which are respectively named according to the calcination temperature S-800, S-900 and S-1000 .

[0023] In order to verify that the technology proposed in the present invention can successfully prepare cobalt phosphide / carbon composite materials at 800-1000 ° C, the X-ray crystal diffraction analysis of the sample is as follows: figure 1 shown.

Embodiment 2

[0025] Add 2 g of freeze-dried yeast (which has been activated and immobilized) into the mortar, and then add 0.882 mL of Co(NO 3 ) 2 The solution was loaded with metal ions, and after careful grinding, the sample was dried in an oven at 60 °C to obtain a solid powder. The obtained solid powder was transferred to a tube furnace, and the temperature was raised from room temperature to 1000 °C at a rate of 5 °C / min under the protection of argon, kept for 4 h, and then cooled down to room temperature under the protection of argon, and the obtained material was After taking it out, it is ground into powder to obtain a composite material named as S-1000 .

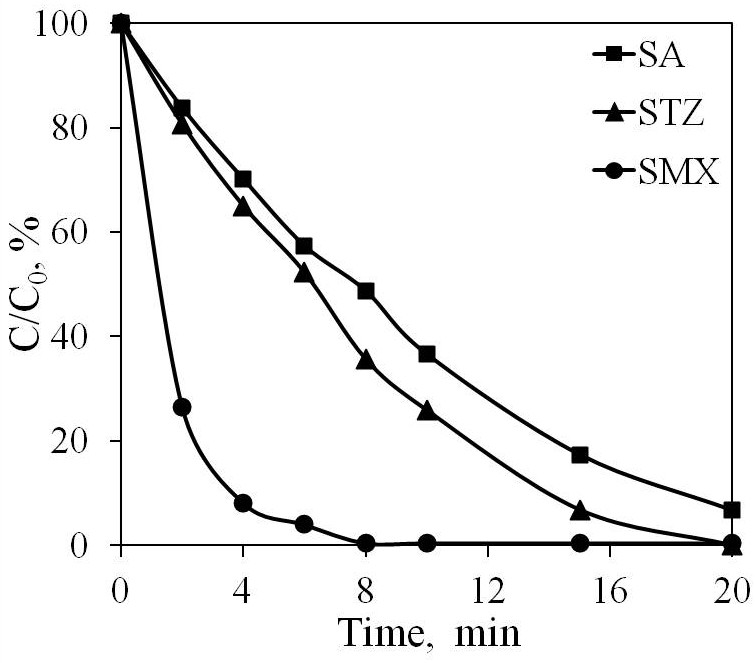

[0026] In order to verify that the cobalt phosphide / carbon composite material prepared by the technology proposed in the present invention can be used for the catalytic degradation of sulfonamide organic pollutants, the experiment and comparison are as follows: prepare 100 mL of sulfanilamide (sulfanilamide, SA ), sulfamethox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com