Low-temperature-resistant low-cobalt positive electrode material and preparation method thereof

A positive electrode material, low temperature resistant technology, applied in positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems affecting the normal use of electric vehicles, poor discharge performance, poor performance, etc., to achieve low preparation cost, improve low temperature performance, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The second aspect of the present invention is to provide a method for preparing the low-temperature resistant and low-cobalt cathode material described in the first aspect of the present invention, the method comprising the following steps:

[0038] Step (1) mixing a low-cobalt precursor, a lithium-containing compound and a modifying additive containing an E element.

[0039]In step 1 of the present invention, the low-cobalt precursor is selected from one or more of oxides, hydroxides, and carbonates containing nickel, cobalt, and manganese; The cobalt precursor can combine the advantages of nickel to increase the specific capacity, manganese to improve the stability and safety performance of the material structure, and cobalt to improve the cycle performance of the material, so that the prepared positive electrode material has both high specific capacity and excellent structural stability. Excellent performance such as high safety performance and good cycle performance...

Embodiment approach

[0041] According to a preferred embodiment of the present invention, the low-cobalt precursor is a hydroxide of nickel-cobalt-manganese, more preferably Ni x co y mn z (OH) 2 , wherein, x+y+z=1, 0.5≤x<1, 0<y<0.2, 0<z<1.

[0042] In the present invention, the lithium-containing compound and the modified additive containing E are also preferably compounds that do not produce other by-products after the reaction and increase the post-treatment process, especially those that do not have strong oxidizing properties, do not produce sulfides, fluorides and impurities Anionic lithium-containing compounds and E-containing modifying additives.

[0043] The lithium-containing compound is selected from one or more of lithium-containing inorganic salts, hydroxides, organic salts and oxides; preferably lithium-containing carbonates, hydroxides, organic salts and oxides One or more; more preferably one or more selected from lithium-containing carbonates, acetates, hydroxides and oxides, ...

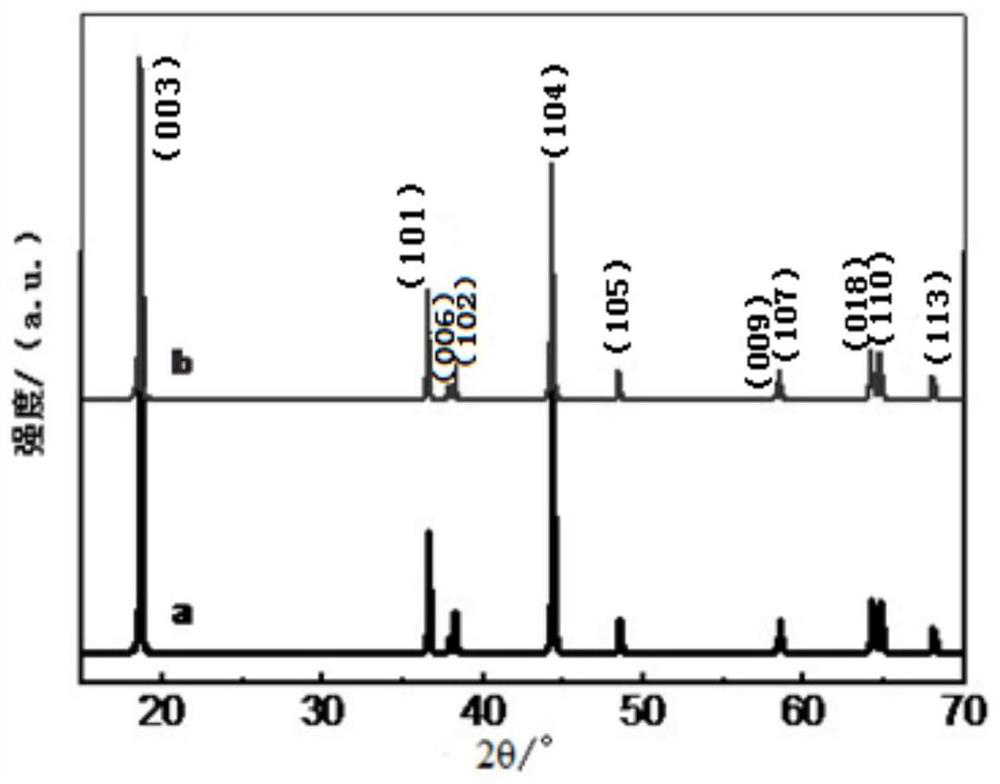

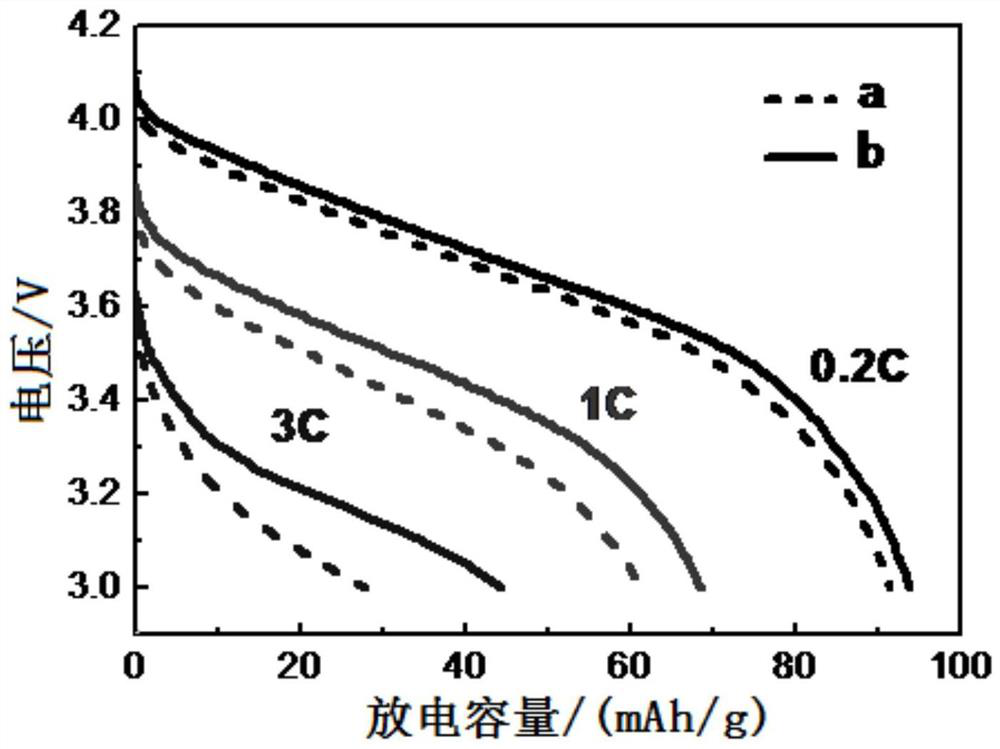

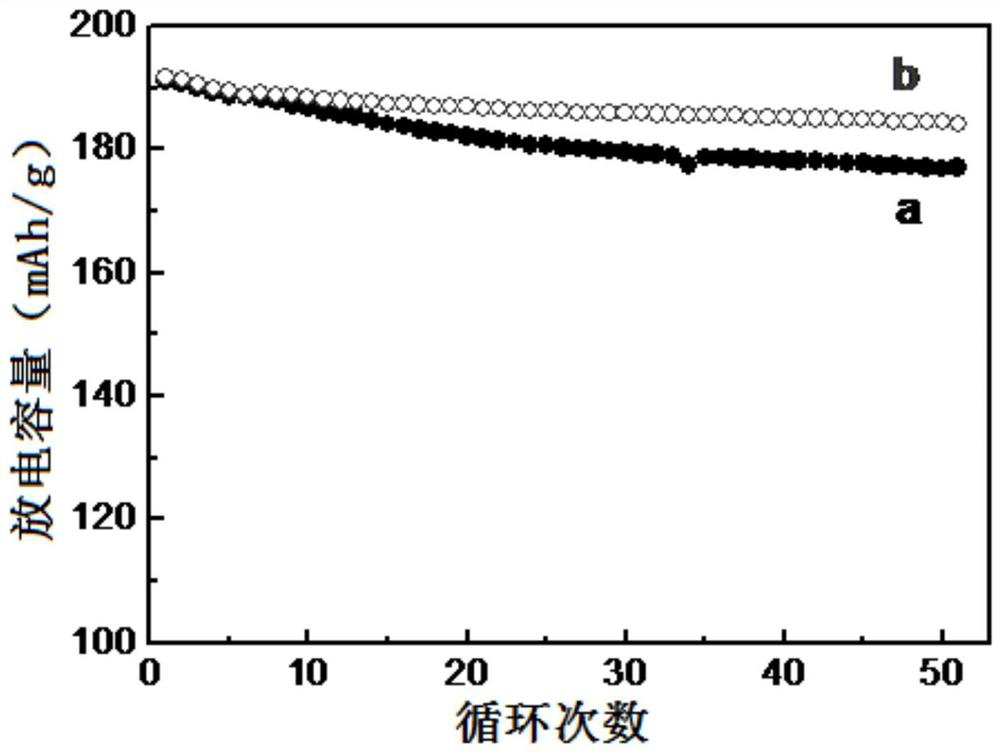

Embodiment 1

[0074] Weigh 34.6g Li respectively 2 CO 3 , 80g Ni 0.55 co 0.15 mn0.30 (OH) 2 and 0.045g WO 3 , mixed with a high-speed mixer for 30 minutes, then placed in a muffle furnace and sintered at 950 ° C for 12 hours, cooled to room temperature naturally, and finally crushed with a pulverizer and passed through a 300-mesh sieve to obtain a doped low-temperature resistant low-cobalt nickel-cobalt-manganese Yuan cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com