Flexible pressure visualization device and preparation method thereof

A pressure and flexible technology, applied in the field of pressure visualization devices and their preparation, can solve the problems of distortion, inability to realize pressure monitoring, complex data collection and processing process, etc., and achieve the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

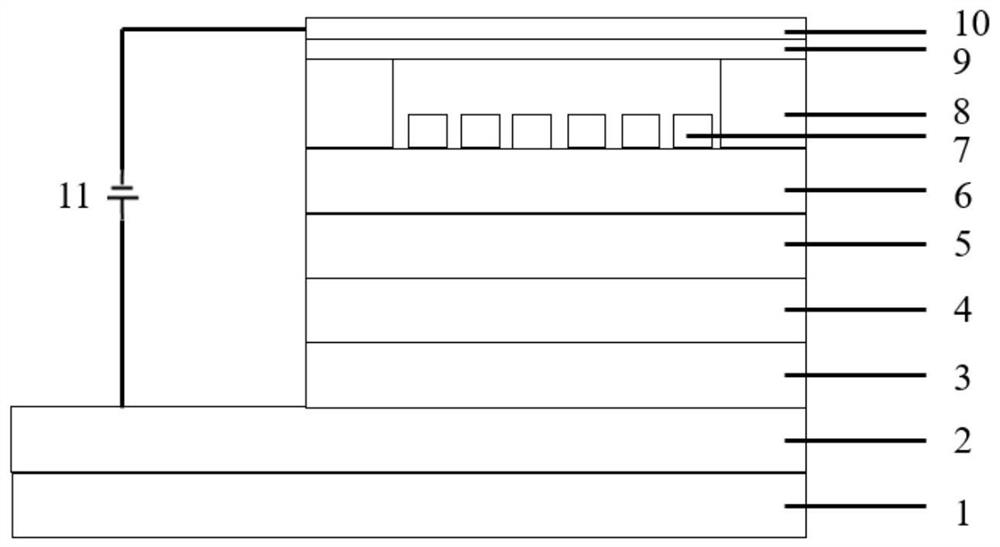

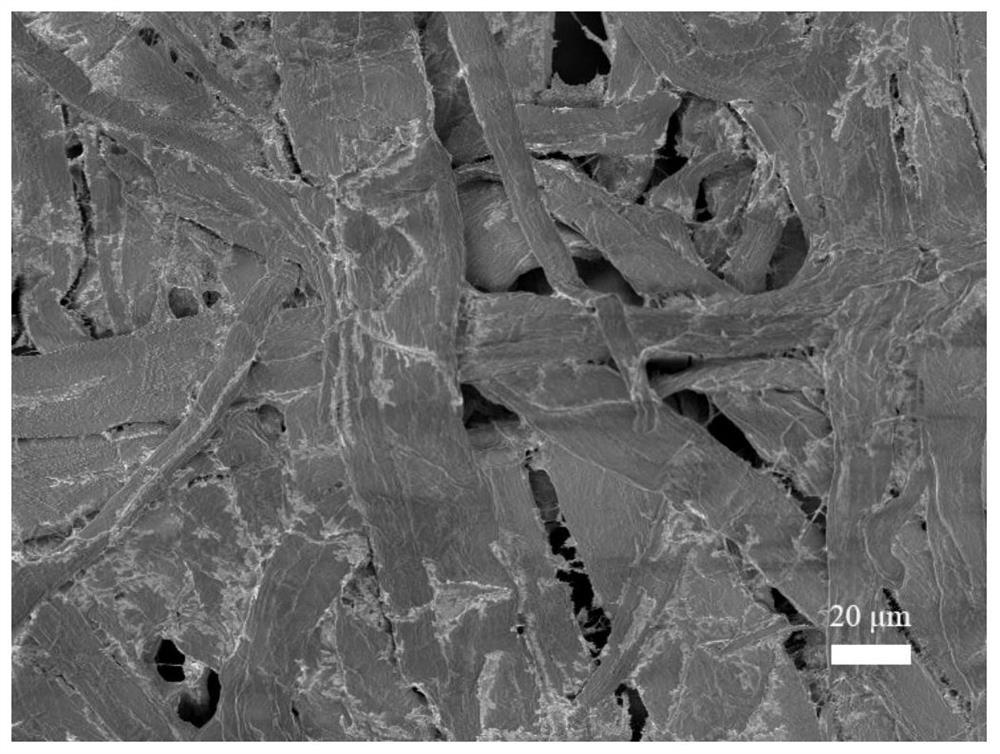

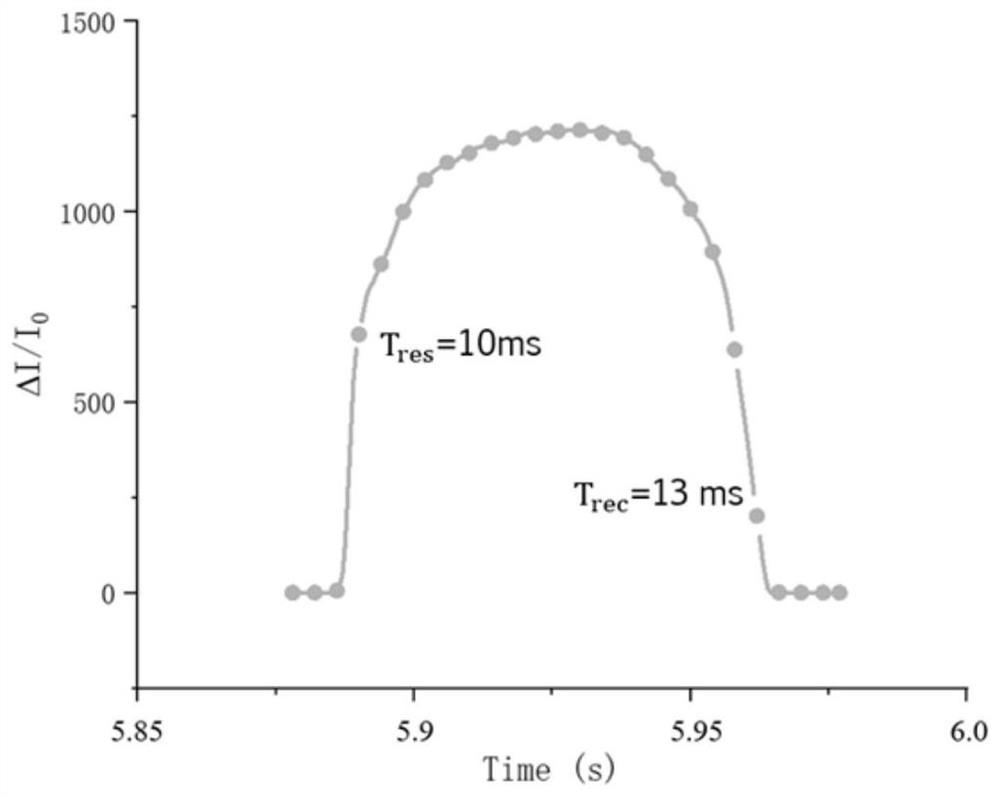

[0032] The present invention provides a flexible pressure visualization device (such as figure 1 ), the key is to make flexible OLED array cathode with flexible pressure sensitive layer (such as figure 1 As stated above, the pressure sensitive layer is composed of a conductive layer and a conductive encapsulation layer) integrated together; further, in order to maintain the high electrical conductivity of the pressure sensitive layer while being able to isolate water and oxygen, the present invention provides a water and oxygen barrier The preparation method of the flexible pressure sensitive layer comprises: using porous non-woven fabric as substrate, silver nanowire solution and carbon nanotube solution as conductive material, PMMA solution as water and oxygen isolation material; first, silver nanowire solution is drip-coated onto a single A layer of non-woven fabric is covered with a second layer of non-woven fabric, and a mixed solution of PMMA solution and carbon nanotube...

Embodiment 1

[0036] The structure of the OLED diode device used in the present invention is as follows from bottom to top:

[0037] ITO / HAT-CN(10nm) / TAPC(40nm) / NPB:Ir(bt) 2 acac(5%)(15nm) / Bepp 2 (40nm) / LiF(1nm) / Al(100nm);

[0038] The preparation method of a flexible pressure visualization device of the present invention comprises the following steps:

[0039] Step 1: Ultrasonic cleaning the flexible substrate with detergent, acetone, deionized water and isopropanol solution in sequence;

[0040] Step 2: After drying, the ITO glass substrates are respectively and Evaporation rate of HAT-CN and TAPC;

[0041] Step 3: Turn on NPB and Ir(bt) at the same time 2 The baffle plate of acac is co-evaporated, and the speeds of the two are respectively and

[0042] Step 4: Separately with and The rate of evaporation Bepp 2 , LiF and an array electrode, where the array electrode is a grid with a size of 0.2×0.2mm, and the spacing between each grid is 0.1mm;

[0043]Step 5: Drop 4ml ...

Embodiment 2

[0046] The structure of the OLED diode device used in the present invention is as follows from bottom to top:

[0047] ITO / HAT-CN(10nm) / TAPC(40nm) / NPB:Ir(bt) 2 acac(5%)(15nm) / Bepp 2 (40nm) / LiF(1nm) / Al(100nm);

[0048] The preparation method of a flexible pressure visualization device of the present invention comprises the following steps:

[0049] Step 1: Ultrasonic cleaning the flexible substrate with detergent, acetone, deionized water and isopropanol solution in sequence;

[0050] Step 2: After drying, the ITO glass substrates are respectively and Evaporation rate of HAT-CN and TAPC;

[0051] Step 3: Turn on NPB and Ir(bt) at the same time 2 The baffle plate of acac is co-evaporated, and the speeds of the two are respectively and

[0052] Step 4: Separately with and The rate of evaporation Bepp 2 , LiF and array electrodes, where the array electrodes are 0.5×0.5mm grids, and the spacing between each grid is 0.1mm;

[0053] Step 5: Drop 4ml of silver nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com