Method for measuring three-dimensional errors of machine tool through combination of ball bar instrument and capacitance displacement sensors

A technology of displacement sensor and ballbar, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problem that the three-dimensional error of the spindle movement of the machine tool cannot be accurately detected, so as to achieve practicality and improve detection The effect of precision and accurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

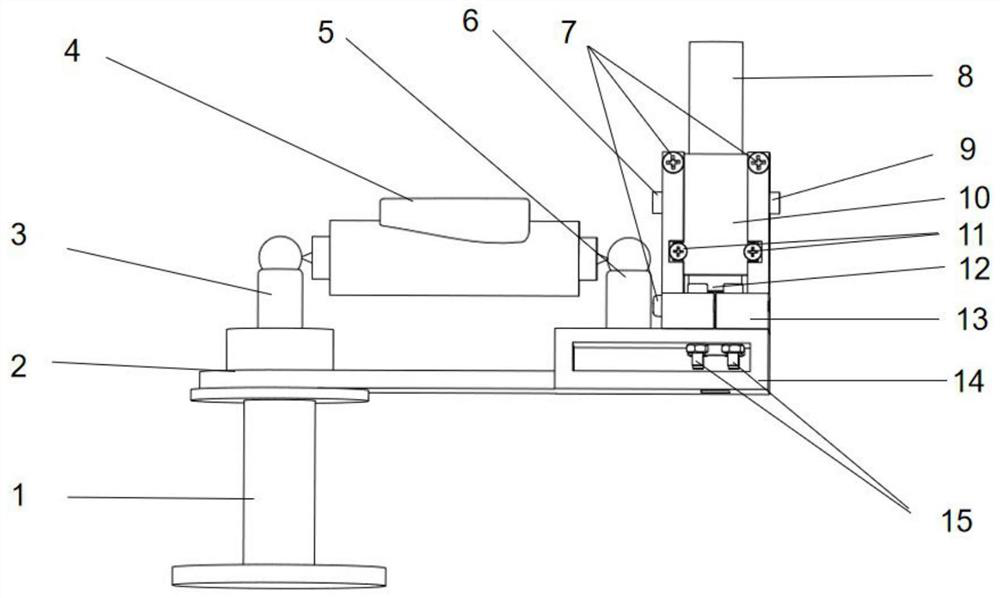

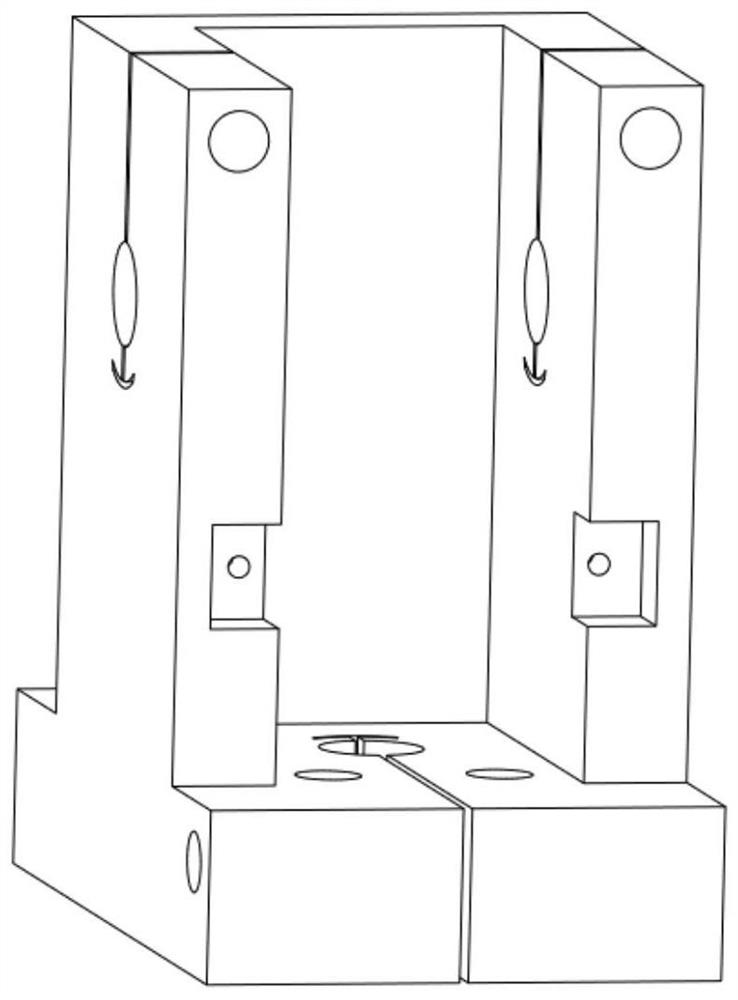

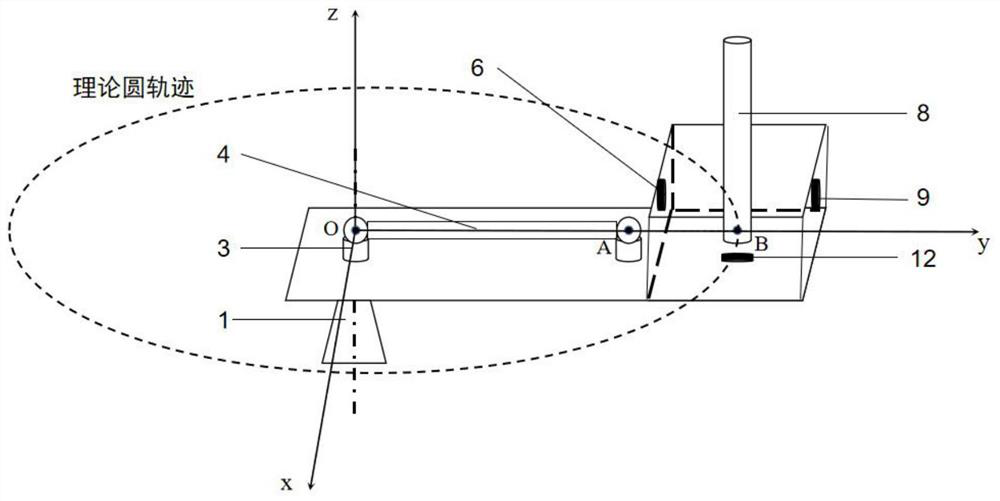

[0037] Such as figure 1 , 2 As shown in and 3, the method of measuring the three-dimensional error of the machine tool by combining the ballbar and the capacitive displacement sensor is as follows:

[0038] Step 1: Fix the base 1 on the machine tool table; one end of the synchronous rotary table 14 is supported on the base through the bearing 2; the ball seat 1 is fixed on the base 1, and the ball seat 2 5 is fixed on the synchronous rotary table On 14, guarantee the magnetic ball-and-socket ball center of ball seat one 3 and the magnetic ball-and-socket ball center of ball seat two 5 (as image 3 Shown at midpoint A) at the same height.

[0039] Step 2. Take the center of the magnetic ball-socket of ball seat 3 as the coordinate origin o. Initially, the line connecting the center of the magnetic ball-socket of ball seat 1 3 and ball seat 2 5 is the direction of the y-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com