A device and method for measuring the rotation angle of a rotating shaft

A technology for measuring the rotation angle and rotating shaft, which is applied in the detection field, can solve the problems such as the inability to measure the rotating shaft angle of CNC machine tools, reduce the measurement process, etc., achieve the effect of continuous measurement, meet the requirements of precision measurement, and simplify the measurement device and measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

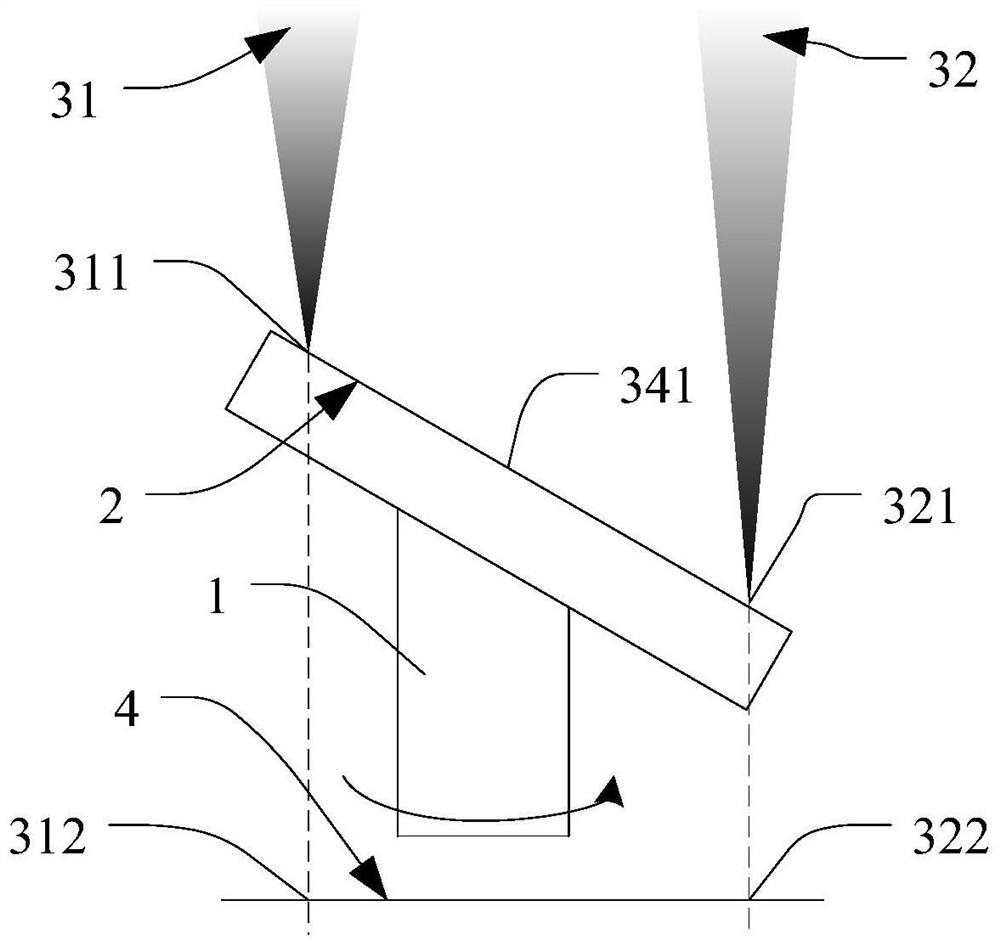

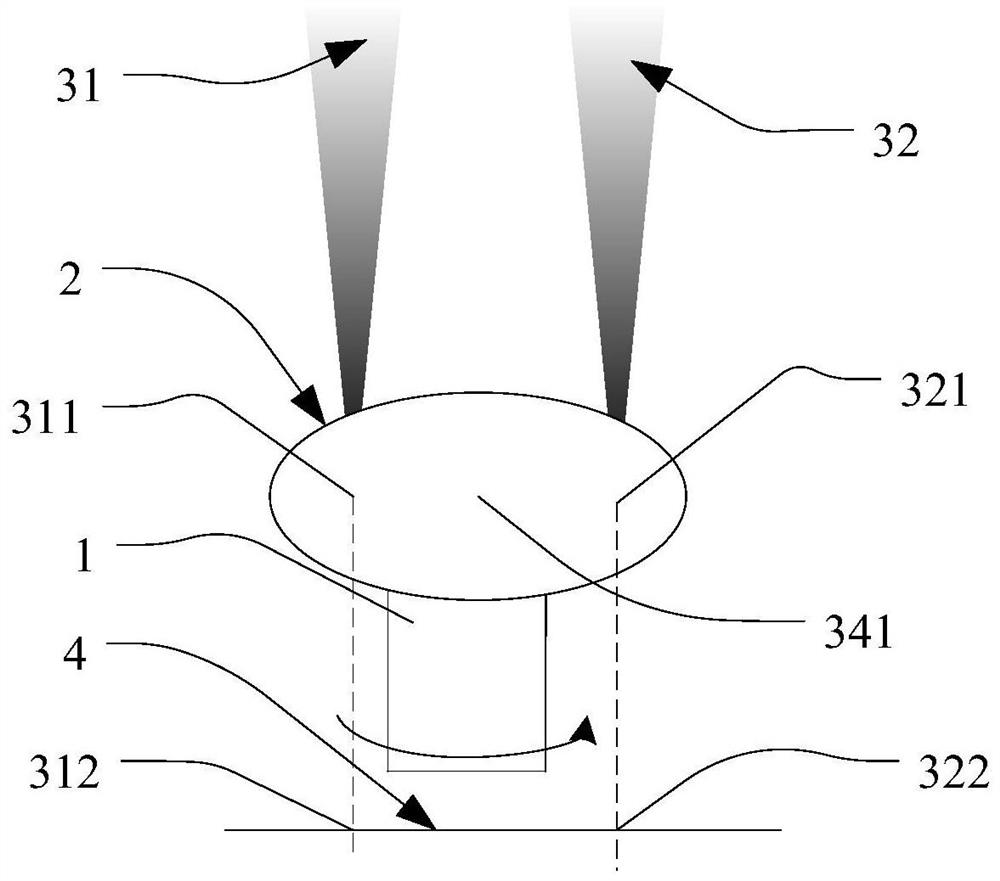

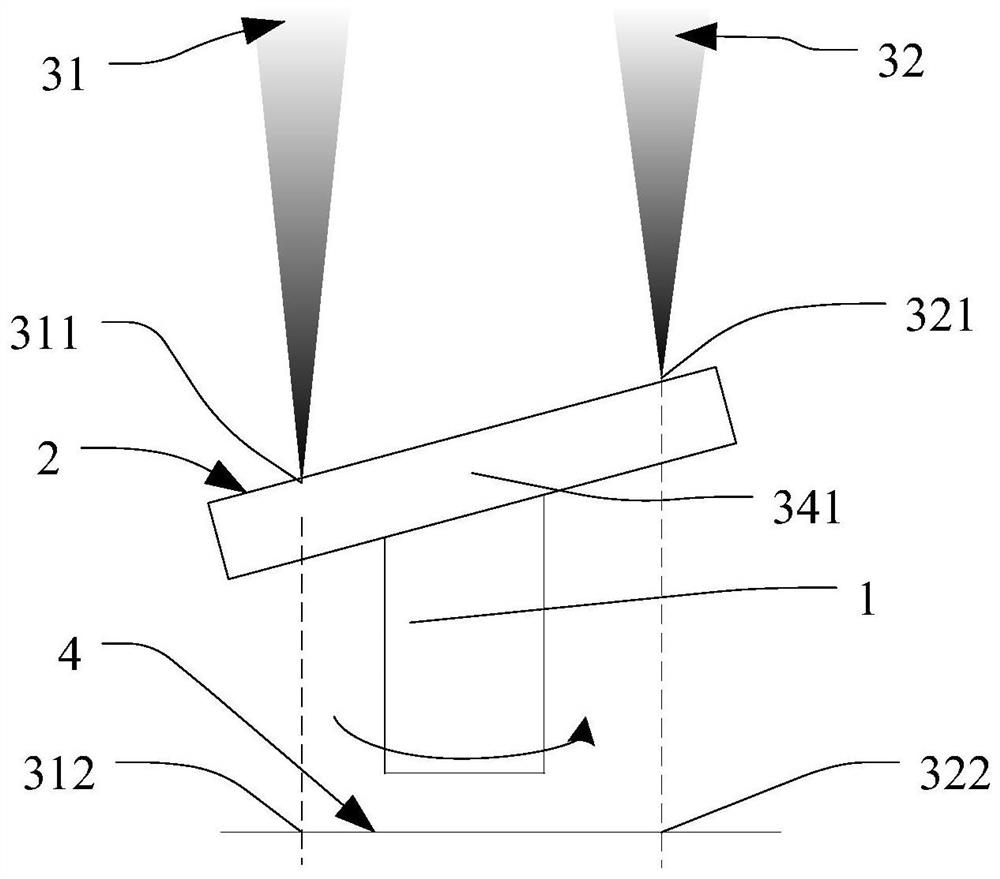

[0059] see figure 1 , in the first embodiment provided by the present invention, the displacement sensor module includes a first displacement sensor 31 and a second displacement sensor 32, the first displacement sensor 31 corresponds to the measurement surface 2 with a first measurement Point 311, the second displacement sensor 32 corresponds to the second measurement point 321 on the measurement surface 2, the first measurement point 311 has a first measurement point projection 312 on the projection plane 4, and the second measurement point 321 is in the projection There is a second measurement point projection 322 on the plane 4. The projection plane 4 is a plane perpendicular to the axis of the rotating shaft. When the rotating shaft 1 rotates, the position of the sensor module remains unchanged, while the first measuring point projection 312 and The position of the second measurement point projection 322 remains unchanged. In addition, the rotating shaft rotation angle mea...

Embodiment 2

[0081] see Figure 8 , wherein the displacement sensor module includes a third displacement sensor 33, the third displacement sensor 33 corresponds to a third measurement point 331 on the measurement surface 2, and the projection plane 4 is perpendicular to the shaft axis A plane of , the third measurement point 331 has a third measurement point projection 332 on the projection plane 4, the intersection point of the shaft axis and the measurement surface is defined as the measurement surface origin 341, the third measurement point 331 and the origin 341 of the measurement surface are defined as the second measurement reference line, and the angle between the second measurement reference line and the axis of the rotating shaft is α. In addition, the rotating shaft angle measuring device also includes a A rotation angle processing unit (not shown in the figure), the rotation angle processing unit is used to calculate the rotation angle of the rotating shaft 1 after receiving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com