A kind of nafion-based composite proton exchange membrane containing cross-linked sulfonated poss, preparation method and application thereof

A proton exchange membrane and cross-linking technology, which is applied in fuel cell proton exchange membranes and polymer functional membranes, can solve the problems of poor dimensional stability and high methanol permeability of Nafion membrane, and achieve high alcohol barrier performance and enhanced methanol barrier performance , thermal stability and strong anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of Nafion-based composite proton exchange membrane containing cross-linked sulfonated POSS

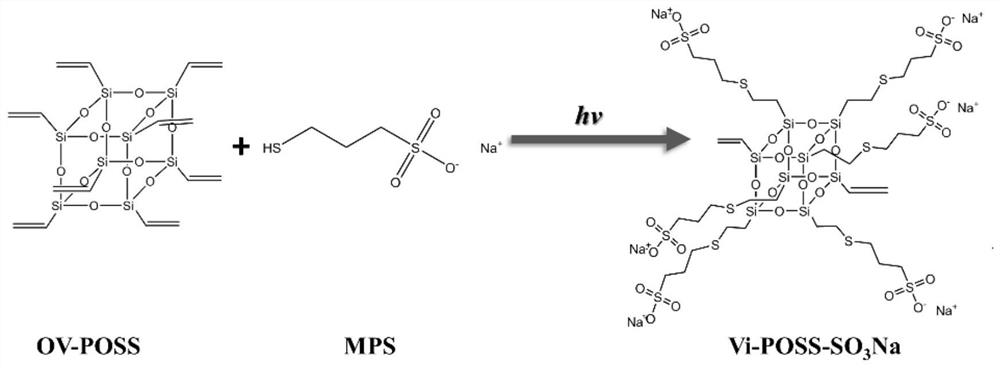

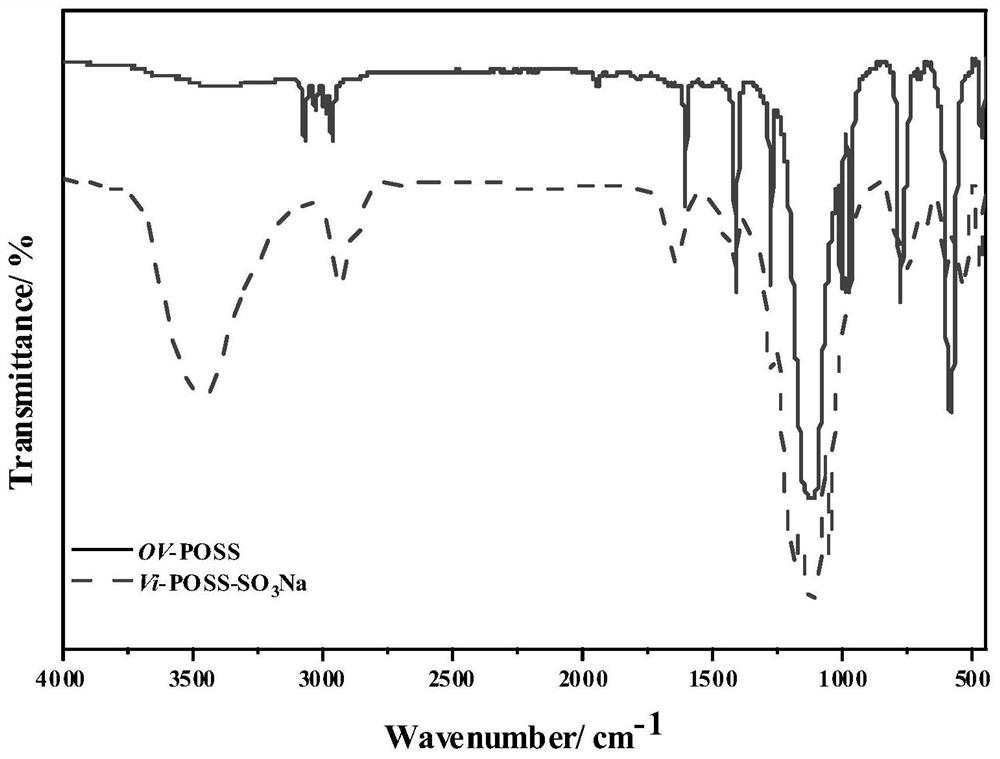

[0039] (1) In a round bottom flask, add 0.1226g of octavinyl cage silsesquioxane, 0.1426g of sodium 3-mercapto-1-propanesulfonate, first add 2.5mL of tetrahydrofuran and 4mL of dimethyl sulfoxide to dissolve the raw materials Disperse evenly and dissolve. Add 5.4 mg of photoinitiator benzoin dimethyl ether and dissolve. Then under magnetic stirring, ultraviolet light was irradiated to react for 2h. A large amount of precipitates were formed in the reaction, and THF in the solvent was removed by rotary evaporation at 50° C. for 40 minutes, and the obtained liquid was poured into 20 mL of absolute ethanol to precipitate precipitates. The obtained precipitate was filtered, washed and dried to obtain vinyl sulfonated siloxane. The reaction equation is as figure 1 .

[0040](2) Preparation of composite proton exchange membrane: first take 0.485g of Nafion...

Embodiment 2

[0041] Example 2: Preparation of Nafion-based composite proton exchange membrane containing cross-linked sulfonated POSS

[0042] (1) In a round bottom flask, add 1.0128g of octavinyl cage silsesquioxane, 1.1406g of sodium 3-mercapto-1-propanesulfonate, first add 20mL of tetrahydrofuran and 20mL of dimethyl sulfoxide to disperse the raw materials Dissolve evenly. Add 40mg of photoinitiator benzoin dimethyl ether and dissolve. Then under magnetic stirring, ultraviolet light was irradiated to react for 2h. A large amount of precipitates were formed in the reaction, and THF in the solvent was removed by rotary evaporation at 50° C. for 40 minutes, and the obtained liquid was poured into 120 mL of absolute ethanol to precipitate precipitates. The obtained precipitate was filtered, washed and dried to obtain vinyl sulfonated siloxane.

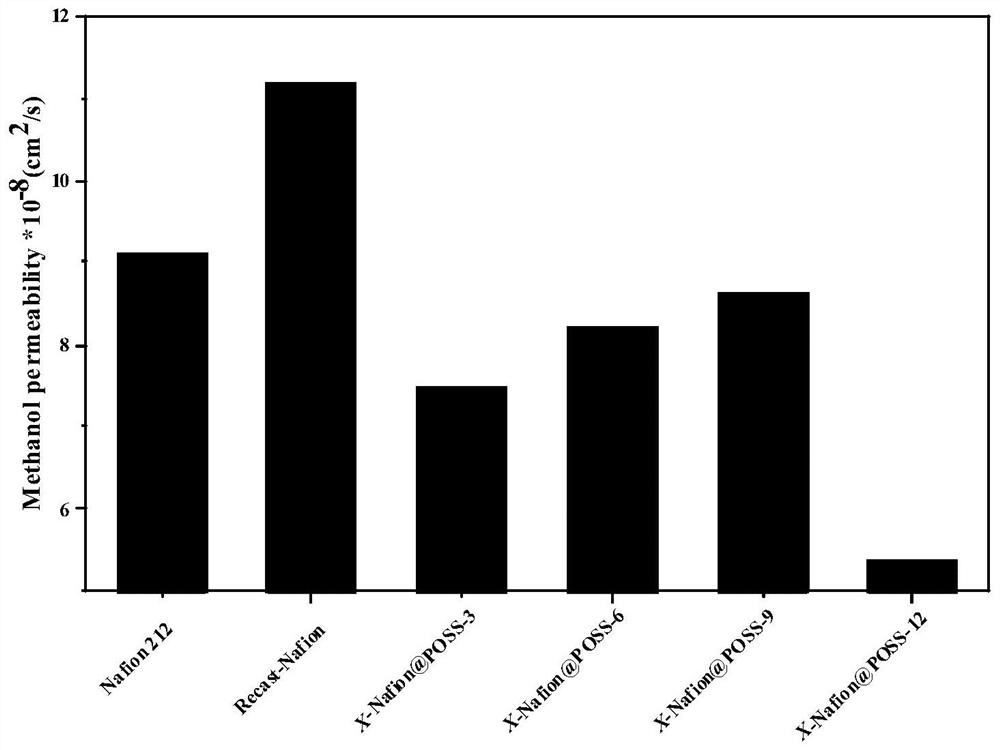

[0043] (2) Preparation of composite proton exchange membrane: first take 0.47g of Nafion 212 membrane, heat and dissolve it in about 1.5mL dimet...

Embodiment 3

[0044] Example 3: Preparation of Nafion-based composite proton exchange membrane containing cross-linked sulfonated POSS

[0045] (1) Preparation of vinyl sulfonated siloxane according to Example 2.

[0046] (2) Preparation of composite proton exchange membrane: First take 0.455g of Nafion 212 membrane, heat and dissolve it in about 1.5mL dimethyl sulfoxide, then take 0.045g of vinyl sulfonated siloxane, add it to Nafion solution, heat and stir, dissolve uniform. The obtained homogeneous solution was scraped on a glass plate with a liquid film thickness of about 1000 μm, and then heated and dried at 70°C to form a film. After the film was formed, it was transferred to an oven at 200°C and heated for crosslinking for 10 hours. The finally obtained composite membrane was soaked and acidified in 0.5 M sulfuric acid solution at 80°C for 12 h to obtain the final Nafion-based composite proton exchange membrane containing cross-linked sulfonated POSS, which was recorded as: X -Naf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com