Process for step-by-step improvement of methane conversion through methane cracking and carbon elimination

A technology for methane and carbon elimination, applied in the field of catalytic conversion of methane to syngas, can solve the problems of high price of Pt, limit industrial application, reduce catalyst stability, etc., and achieve the effect of being beneficial to utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

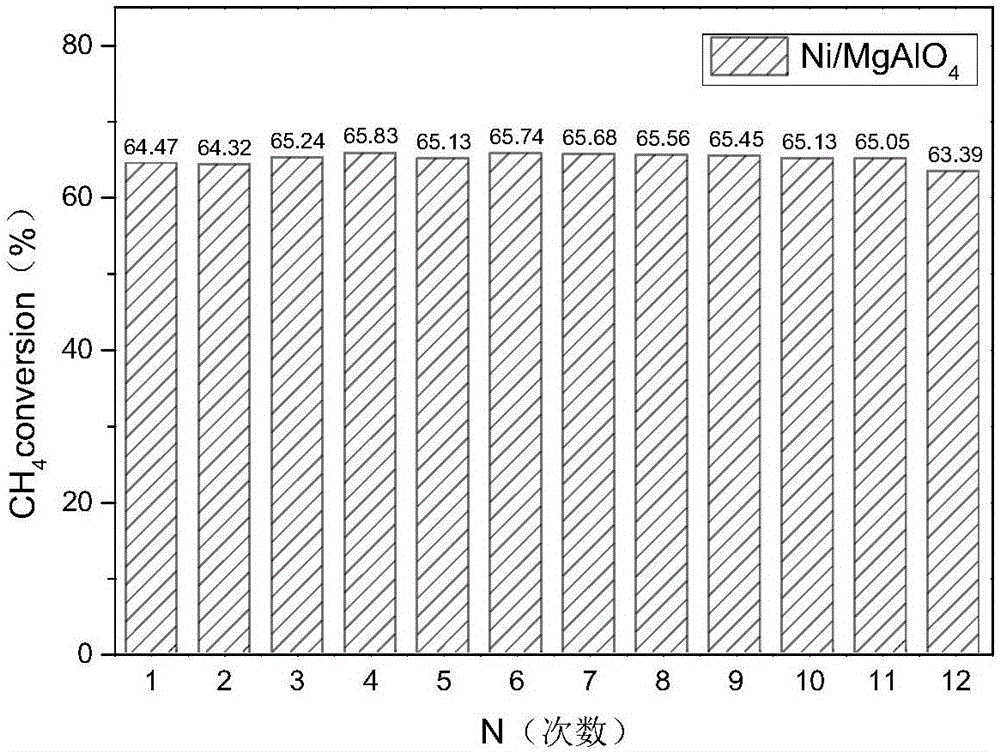

Embodiment 1

[0043] Into the fixed bed packed with catalyst, pass CH 4 When the mixed gas with Ar is used for the methane carbon dioxide reforming reaction, the methane cracking reaction is carried out at a temperature of 450°C and a pressure of 0.1 MPa. The methane cracking reaction is carried out for 10 minutes, and the gas is detected online by gas chromatography at the 5th minute. Element. After 10 minutes of methane cracking reaction, switch to 30mL / min Ar gas purge for 5 minutes, and then pass CO 2 Mixed gas with Ar, carry out carbon removal reaction at a temperature of 450°C and a pressure of 0.1MP. The reaction is carried out for 15 minutes. After the reaction is completed, it is purged with 30mL / min Ar gas for 5 minutes to complete a methane conversion reaction, and then crack the methane And the carbon removal reaction cycle continues, and 12 methane conversion reactions are completed. Among them, when reacting, the space velocity is 3.6x10 4 mL / (h·gcat), CH 4 The flow rate o...

Embodiment 2

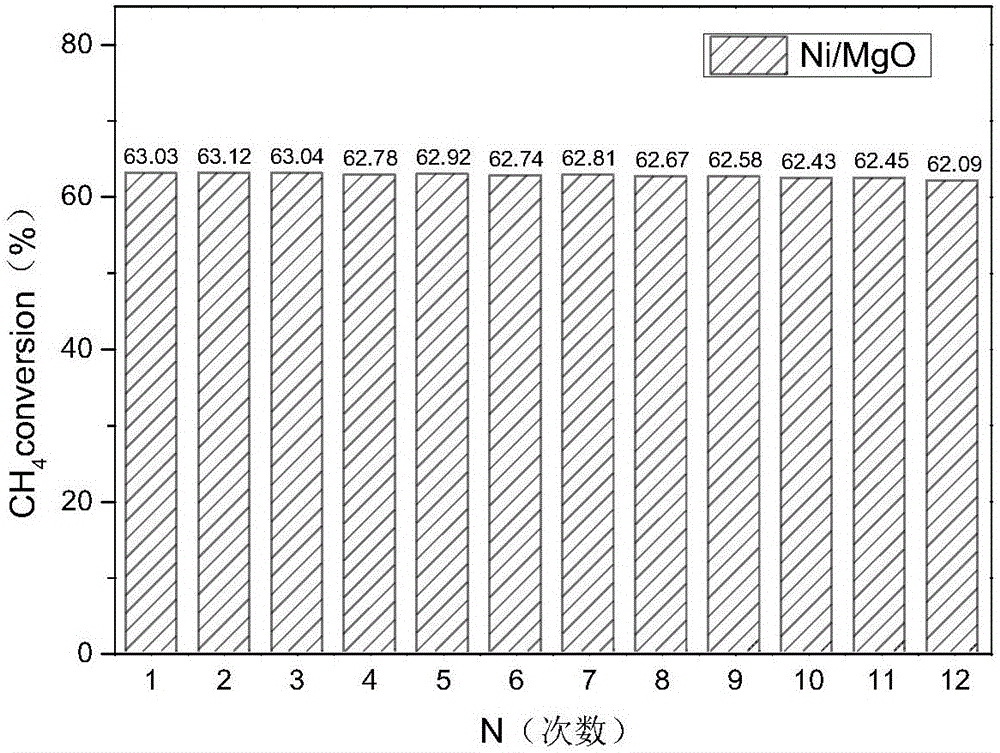

[0045] The difference from Example 1 is that the catalyst is Ni / MgO treated with cold plasma.

Embodiment 3

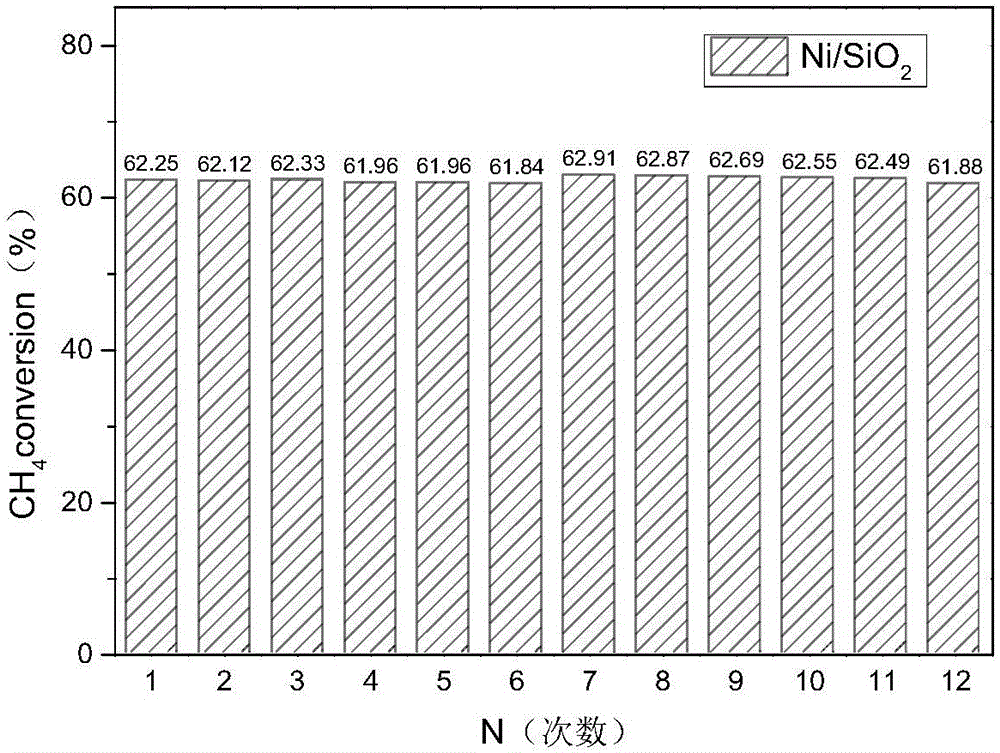

[0047] Unlike Example 1, the catalyst is cold plasma treated Ni / SiO 2 .

[0048] Such as figure 1 , figure 2 , image 3 Shown, use the method for stepwise reaction among the embodiment 1-3, respectively with the Ni / MgAlO that cold plasma is processed 4 ,, Ni / MgO, Ni / SiO 2 When the methane carbon dioxide reforming reaction is carried out as a catalyst, the initial conversion rate of methane is between 64.67%-62.25%, and the conversion rate of methane is between 63.39%-61.88 after undergoing 12 methane conversion reactions, and there is no obvious decline, indicating that Using the method for reaction, the catalyst has better stability and can maintain the methane carbon dioxide reforming reaction for a long time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com