Silicon oxide composite boron-doped carbon nanotube film as well as preparation method and application thereof

A carbon nanotube film, boron doping technology, applied in the direction of carbon nanotubes, nanocarbon, gaseous chemical plating, etc., can solve the problem that boron-doped carbon nanotube materials cannot meet the flexible film electrodes and other problems, and achieve self-supporting Good, simple process flow, improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

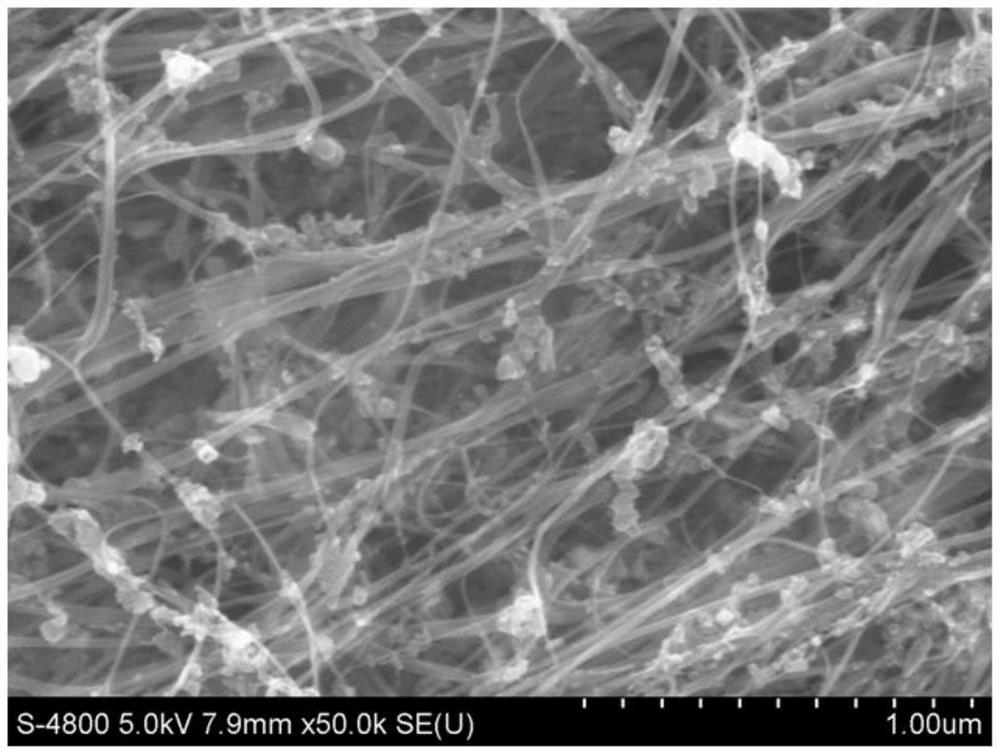

Embodiment 1

[0032] (1) Completely seal the vertical CVD furnace, continuously feed 100 sccm of Ar to remove the air in the furnace, then raise the temperature of the vertical CVD furnace to 1150° C. through the temperature controller, and keep it warm for 4 hours to prepare the carbon nanotube-based substrate for subsequent carbon nanotubes. The growth of the composite film provides a constant temperature environment;

[0033] (2) Weigh ethanol, ferrocene, thiophene according to the mass ratio of 95:1.5:1, be mixed into solution, wherein ethanol is as carbon source, ferrocene is as catalyst, and thiophene is as promotor; Then on the basis of above-mentioned mixed solution Add 2wt.% boric acid and 0.2wt.% tetraethyl orthosilicate as the boron source and silicon source respectively, and disperse the above solution by ultrasonic for 10min at a temperature of 50°C to obtain a uniform dispersion and then transfer to a syringe as a precursor solution;

[0034] (3) After steps (1) and (2) are c...

Embodiment 2

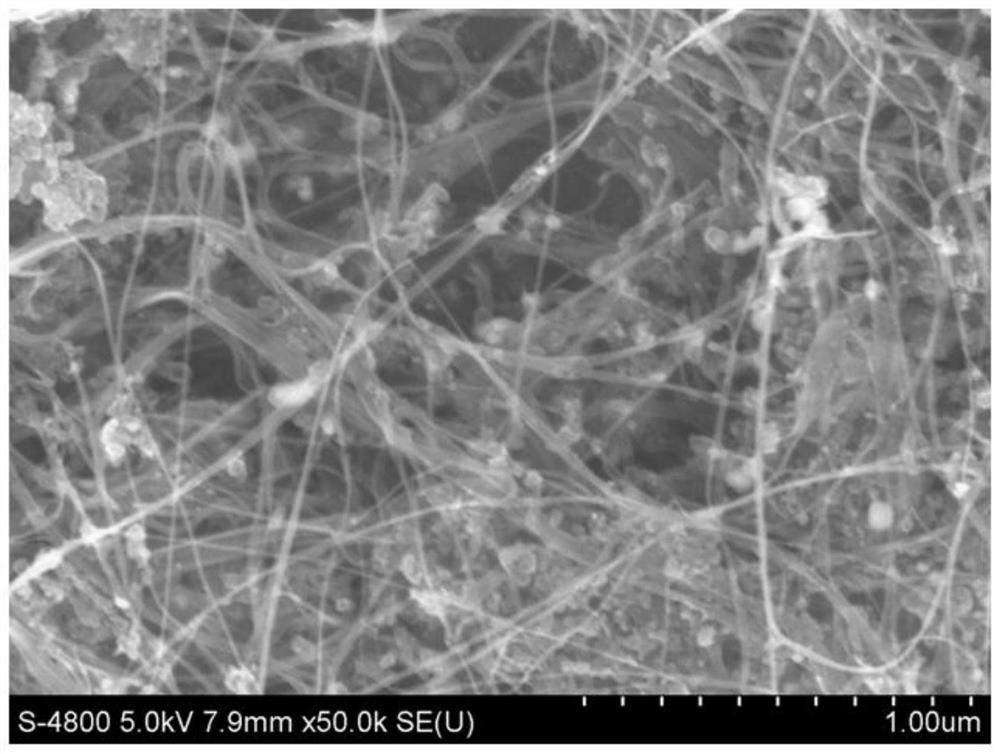

[0037] (1) Completely seal the vertical CVD furnace, continuously feed 100 sccm of Ar to remove the air in the furnace, then raise the temperature of the vertical CVD furnace to 1150° C. through the temperature controller, and keep it warm for 4 hours to prepare the carbon nanotube-based substrate for subsequent carbon nanotubes. The growth of the composite film provides a constant temperature environment;

[0038] (2) Weigh ethanol, ferrocene, thiophene according to the mass ratio of 95:1.5:1, be mixed into solution, wherein ethanol is as carbon source, ferrocene is as catalyst, and thiophene is as promotor; Then on the basis of above-mentioned mixed solution Add 2wt.% boric acid and 0.5wt.% tetraethyl orthosilicate as the boron source and silicon source respectively, and disperse the above solution by ultrasonic for 10min at a temperature of 50°C to obtain a uniform dispersion and then transfer to a syringe as a precursor solution;

[0039] (3) After steps (1) and (2) are c...

Embodiment 3

[0042] (1) Completely seal the vertical CVD furnace, continuously feed 100 sccm of Ar to remove the air in the furnace, then raise the temperature of the vertical CVD furnace to 1150° C. through the temperature controller, and keep it warm for 4 hours to prepare the carbon nanotube-based substrate for subsequent carbon nanotubes. The growth of the composite film provides a constant temperature environment;

[0043] (2) Weigh ethanol, ferrocene, thiophene according to the mass ratio of 95:1.5:1, be mixed into solution, wherein ethanol is as carbon source, ferrocene is as catalyst, and thiophene is as promotor; Then on the basis of above-mentioned mixed solution Add 2wt.% boric acid and 1wt.% tetraethyl orthosilicate as boron source and silicon source respectively, and disperse the above solution by ultrasonic for 10min at a temperature of 50°C to obtain a uniform dispersion and transfer it to Syringes, as precursor solutions;

[0044] (3) After steps (1) and (2) are completed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com