Special-shaped polycrystalline diamond compact with secondary crushing function

A technology of polycrystalline diamond and secondary crushing, which is applied to drilling equipment, earthwork drilling, drill bits, etc. It can solve the problems of reducing the life of the composite sheet, increasing the efficiency of the composite sheet, and the application effect of the plastic formation is not obvious, so as to improve the rock breaking efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

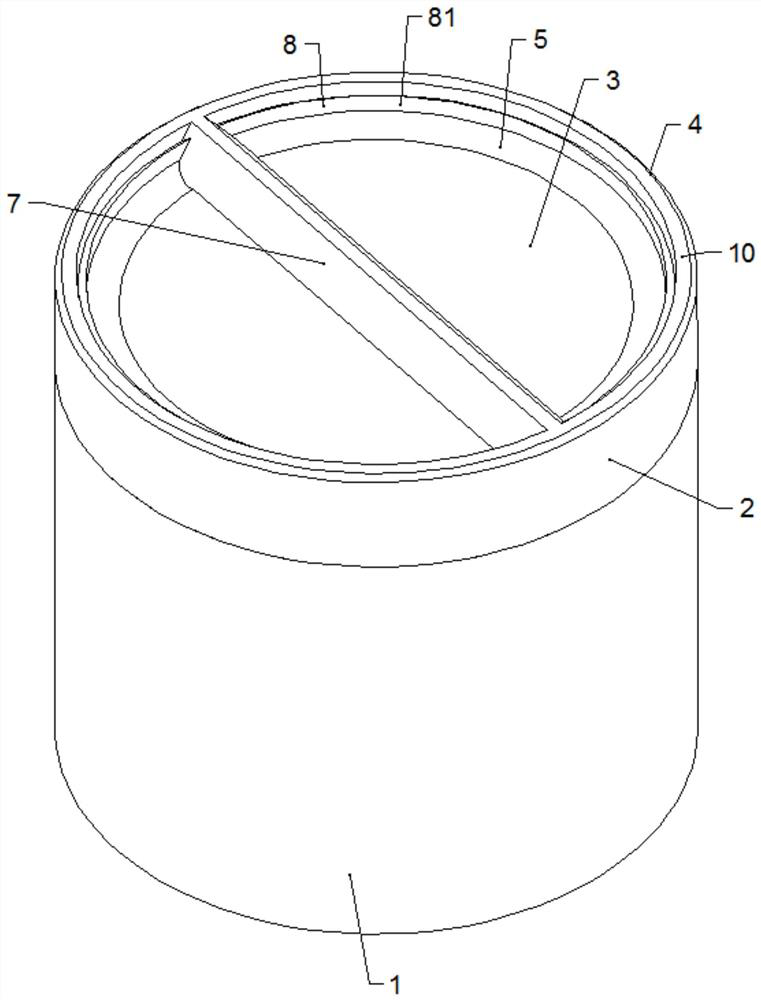

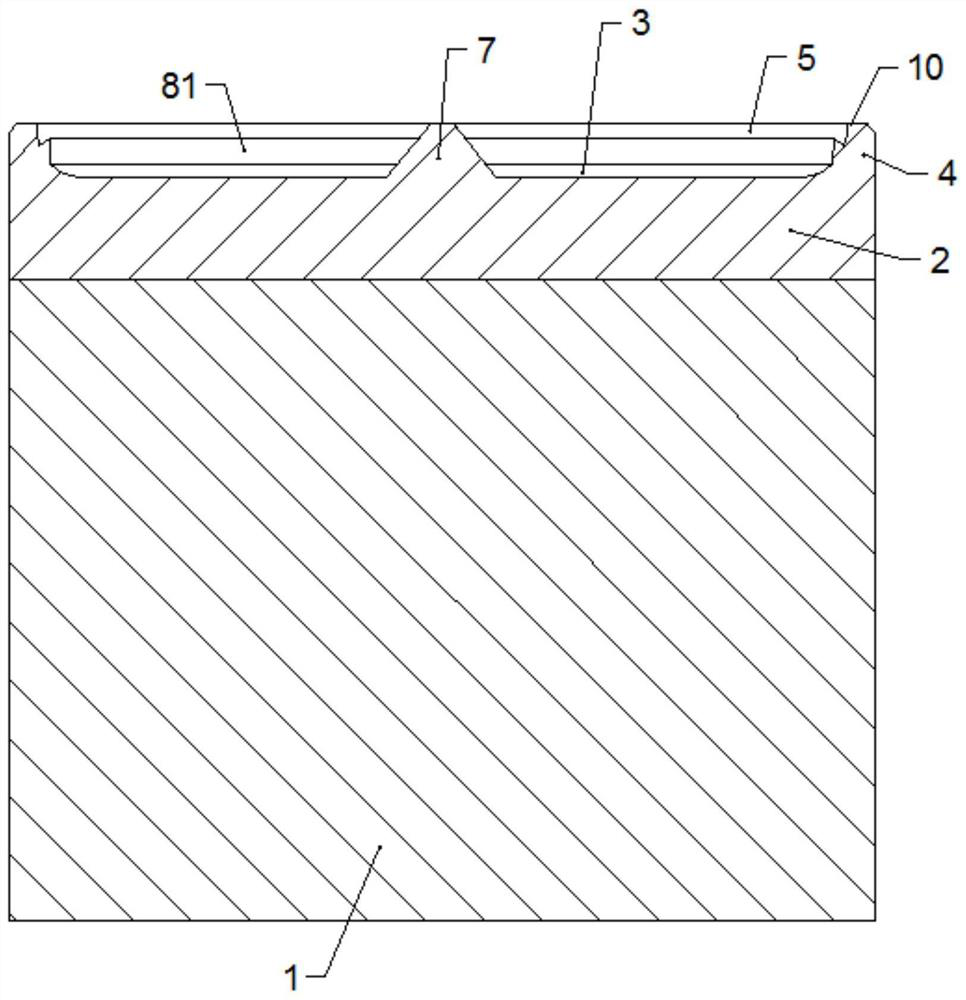

[0066] Such as Figure 6 Shown is an axonometric view of one embodiment of the present invention, comprising a polycrystalline diamond layer 2 and a cemented carbide substrate 1 . The upper surface of the polycrystalline diamond layer 2 is provided with a chip flute 5 , a crushing part 7 , a cutting edge 10 , and a groove 3 . The characteristics and functions of each part are as follows:

[0067] The chip volume groove 5 is an inclined plane (the chip volume groove 5 can be designed as an arc surface structure or a plane structure), and the angle between the chip volume groove 5 and the horizontal plane is 15°-30°, which can remove the cut rock The cuttings are rolled up, causing the cuttings to curl and break;

[0068] The number of crushing parts-7 is 3. On the one hand, it can strengthen the structural strength of the composite sheet, and on the other hand, it can perform secondary crushing of large-grained rock chips, reduce cutting force, and improve cutting efficiency....

Embodiment 2

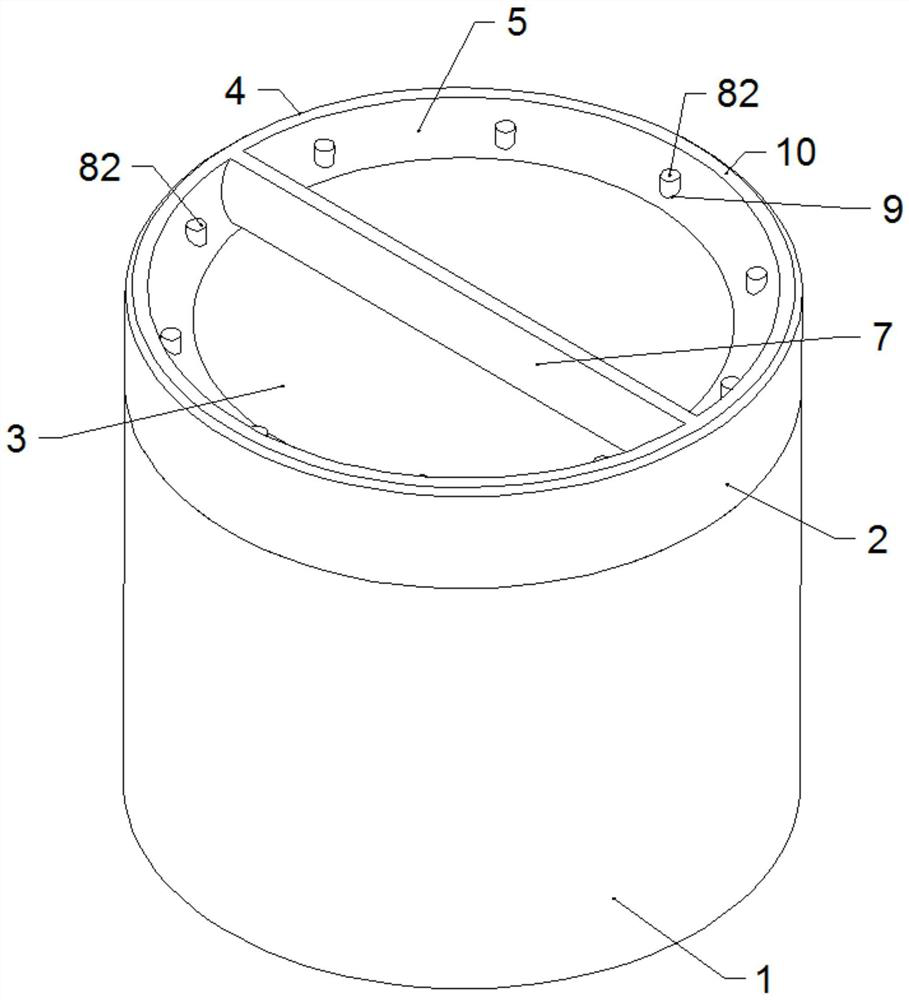

[0073] Such as Figure 7 Shown is an axonometric view of another embodiment of the invention comprising a polycrystalline diamond layer 2 and a cemented carbide substrate 1 . The upper surface of the polycrystalline diamond layer includes a chip flute 5 , a broken portion 7 , a cutting edge 10 , and a groove 3 . The characteristics and functions of each part are as follows:

[0074] The included angle between the chip rolling groove 5 and the horizontal plane is 15°-30°, which can roll up the cutting cuttings and make the cuttings curl and break;

[0075] The number of crushing parts-7 is 2. On the one hand, it can strengthen the structural strength of the composite sheet, and on the other hand, it can carry out secondary crushing of large-grained rock debris, reduce cutting force, and improve cutting efficiency. When the crushing part on one side is worn out, the crushing part on the other side can continue to function by rotating the composite sheet.

[0076] The groove 3...

Embodiment 3

[0080] Such as Figure 8 Shown is an axonometric view of another embodiment of the invention comprising a polycrystalline diamond layer 2 and a cemented carbide substrate 1 . The upper surface of the polycrystalline diamond layer includes a chip flute 5 , a broken portion 7 , a cutting edge 10 , and a groove 3 . The characteristics and functions of each part are as follows:

[0081] The included angle between the chip rolling groove 5 and the horizontal plane is 15°-30°, which can roll up the cutting cuttings and make the cuttings curl and break;

[0082] The number of crushing parts-7 is 4. On the one hand, it can strengthen the structural strength of the composite sheet, and on the other hand, it can perform secondary crushing of large-grained rock chips, reduce cutting force, and improve cutting efficiency. When the crushing part on one side is worn out, the crushing part on the other side can continue to function by rotating the composite sheet.

[0083] The groove 3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com