Tea leaf production and processing equipment and tea leaf processing technological method

A processing equipment and tea technology, which is applied in the field of tea production and processing equipment, can solve problems such as tea damage, tea dregs burnt black, affecting the taste and appearance of tea, and achieve the effect of improving the processing effect and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

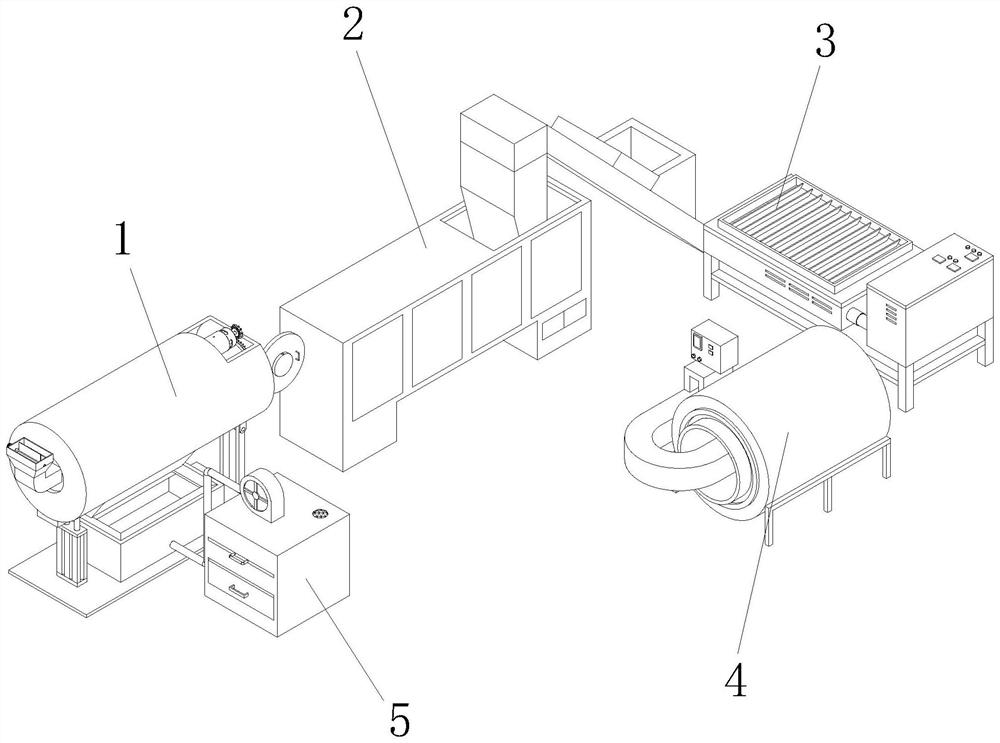

[0044] like Figure 1-8 As shown, a tea production and processing equipment and a tea processing technology method include a main fried tea component 1;

[0045] Reconditioning machine 2, reconditioning machine 2 is used to reconditioning the tea leaves fried by the main tea-frying component 1;

[0046] Trimmer 3, Trimmer 3 is used to soften the tissue of the tea leaves and volatilize the smell of grass;

[0047] The frying dryer 4, the frying dryer 4 is used to fry and dry the tea leaves after stripping;

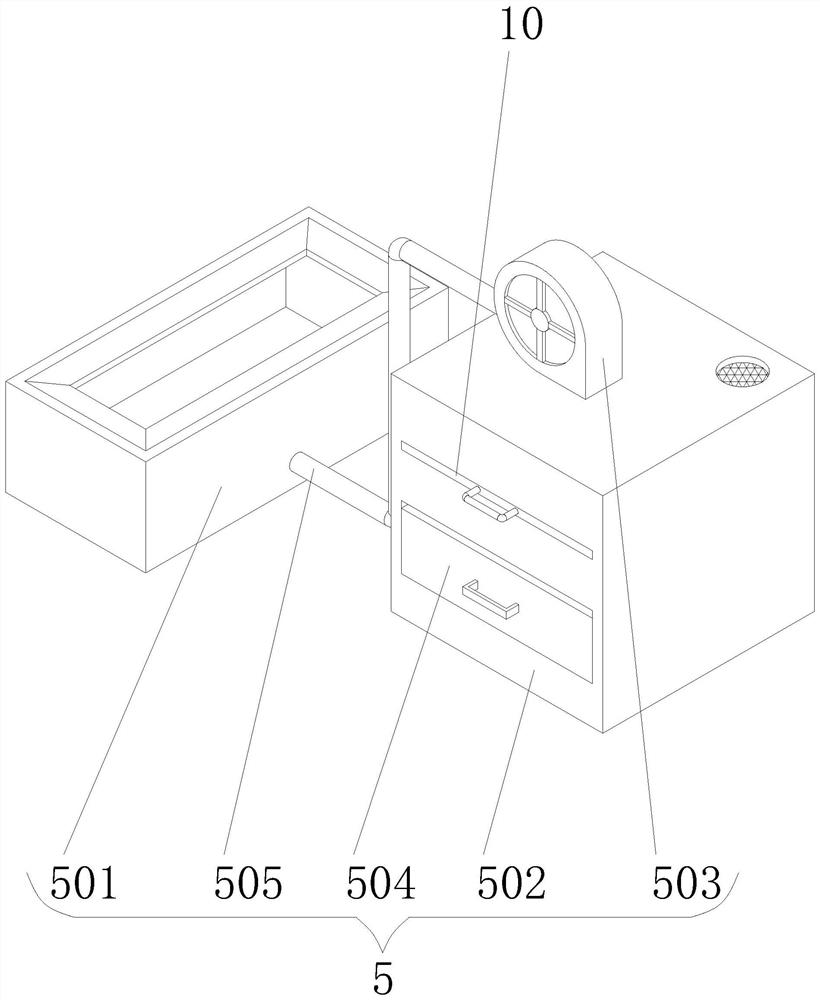

[0048] The tea residue processing component 5 is arranged at the bottom of the main fried tea component 1 .

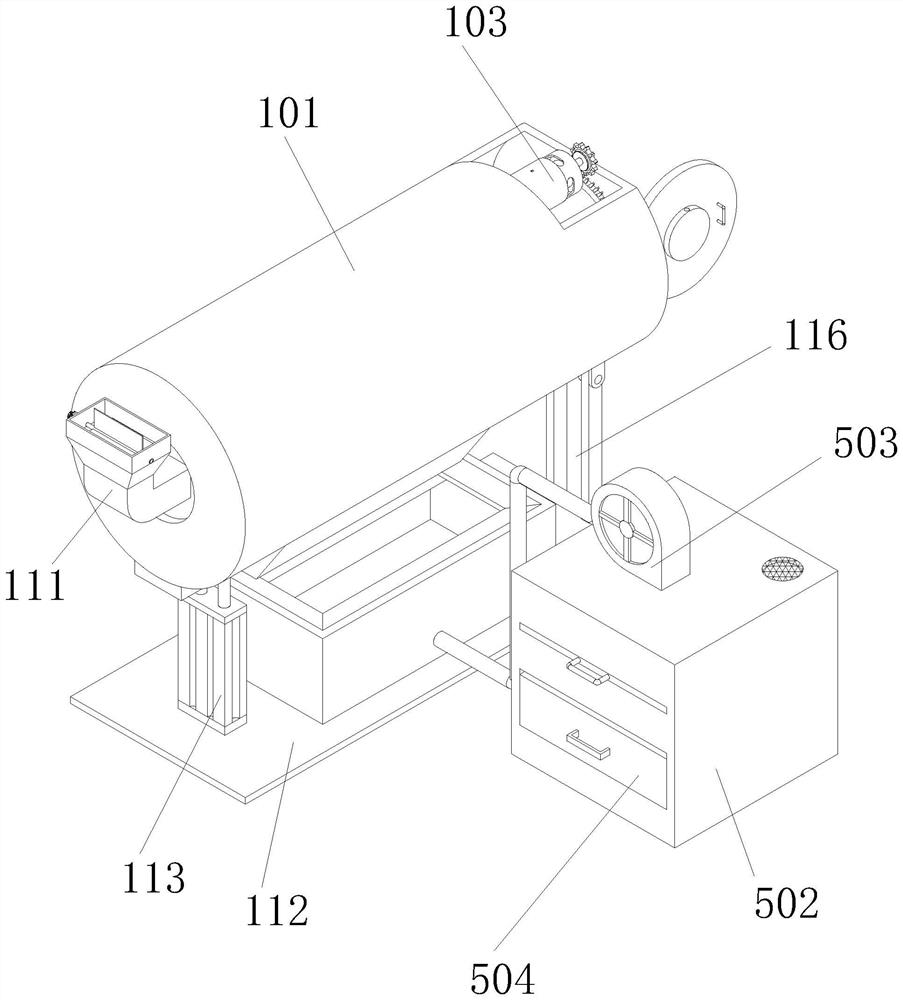

[0049] In this example, the main fried tea assembly 1 includes a main body shell 101, an inner drum 102, a drive motor 103, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com