Preparation process for hemp oil

A production process and hemp oil technology, applied in the field of technology, can solve the problems of low oil yield of hemp seeds, difficult to remove impurities from hemp oil, poor taste of hemp oil and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

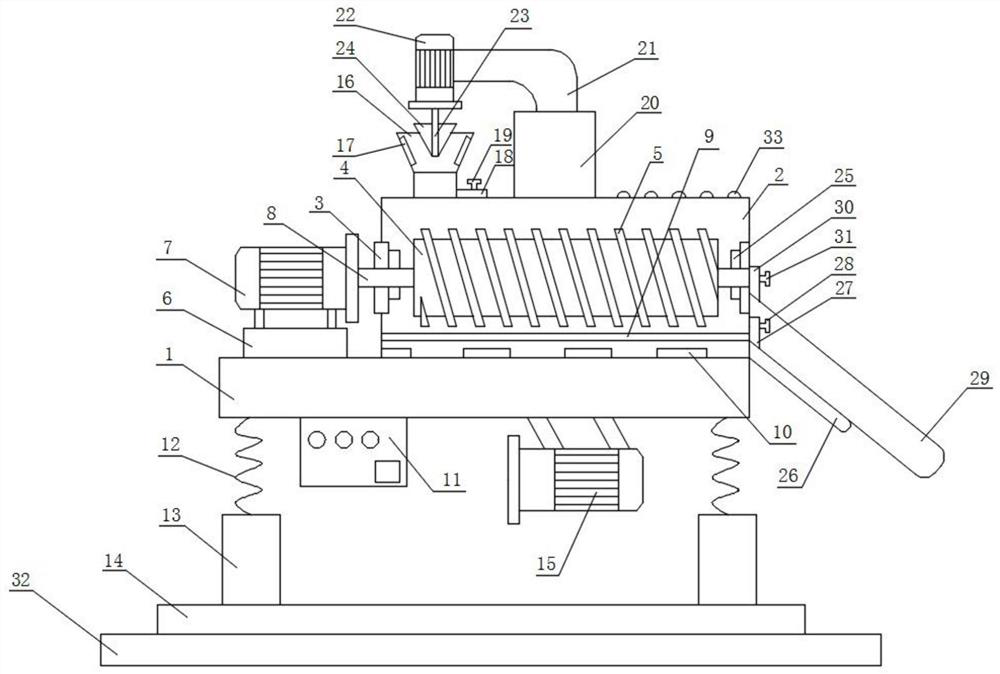

[0030] like Figure 1-2 Shown, the present invention is used for the manufacture craft of hemp oil, and the concrete realization mode of the present invention is: in the existing hemp oil manufacture craft, be difficult to stir-fry hemp seed evenly, cause hemp seed oil yield rate is lower; Squeeze It is difficult to remove impurities in the hemp oil, resulting in poor taste of the hemp oil. The hemp seeds are screened in three stages through the screening device, and the impurities contained in the hemp seeds are selected, and the hemp seeds are separated from the impurities through the screening device; The hemp seeds screened in the previous step pass through the stir-frying device to remove the excess water contained in the hemp seeds, so that the water content in the hemp seeds is within the range of low-temperature cold pressing; the hemp seeds stir-fried in the previous step are transported to Extracting machine, through the extracting machine, the hemp seeds are pressed...

Embodiment 2

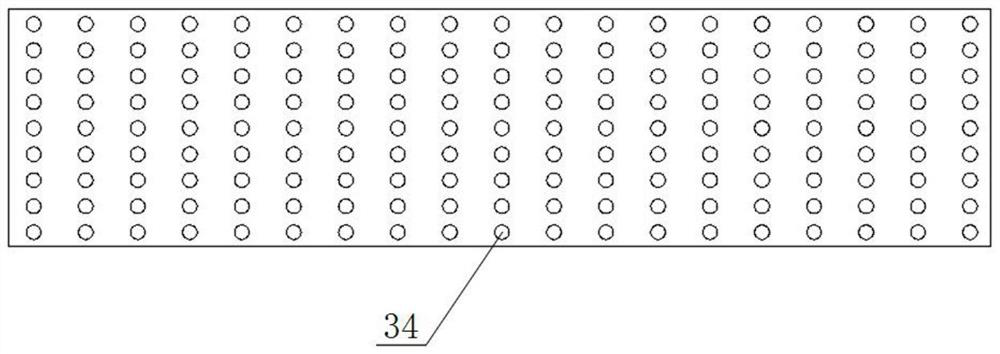

[0033] Based on Example 1, such as Figure 1-2 As shown, the present invention is used in the manufacturing process of hemp oil, and the stir-frying device includes a base, and the base 1 is connected with a stir-fry tube 2, and the stir-fry tube 2 is provided with a first passage for the hemp seeds to pass through. The drum 2 is provided with a feeding port, one end of the frying drum 2 is provided with a first discharge port and a second discharge port, the two ends of the frying drum 2 are fixed with rotating bearings 3, and the frying drum 2 is provided with a rotary drum 4 , the rotating drum 4 is located in the channel, the two ends of the rotating drum 4 are connected with the inner wall of the rotating bearing 3, the rotating drum 4 is provided with continuous frying teeth 5, the base 1 is provided with a first fixing seat 6, and the first fixing seat 6 The first motor 7 is connected to the top, and the first motor 7 is connected to one end of the rotating drum 4 throu...

Embodiment 3

[0037] Based on the above examples, such as figure 1Shown, the present invention is used for the manufacture craft of hemp oil, is connected with feeding hopper 16 above the feed inlet, is provided with the second passage that passes through for hemp seed in the feeding hopper 16, is provided with several in the feeding hopper 16. The second heating block 17, the second heating block 17 is electrically connected with the heating controller 11, the connection between the feed hopper 16 and the frying drum 2 is provided with a first material control block 18, and the first material control block 18 is provided with a first material control block 18. A locking bolt 19, a second fixing seat 20 is arranged on the frying tube 2, a fixing frame 21 is connected to the second fixing seat 20, a second motor 22 is connected to the other end of the fixing frame 21, and a second motor 22 is connected below the second motor 22. The second rotating rod 23 is connected with the stirring blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com