A magnetic coagulation high gradient magnetic separator

A high-gradient magnetic separation and magnetic coagulation technology, applied in high-gradient magnetic separators, magnetic separation, solid separation, etc., can solve the problems of low magnetic field strength, fast wear, low recovery rate, etc., to improve the recovery rate of magnetic powder, Guaranteed flipping effect and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-4 The application is described in further detail.

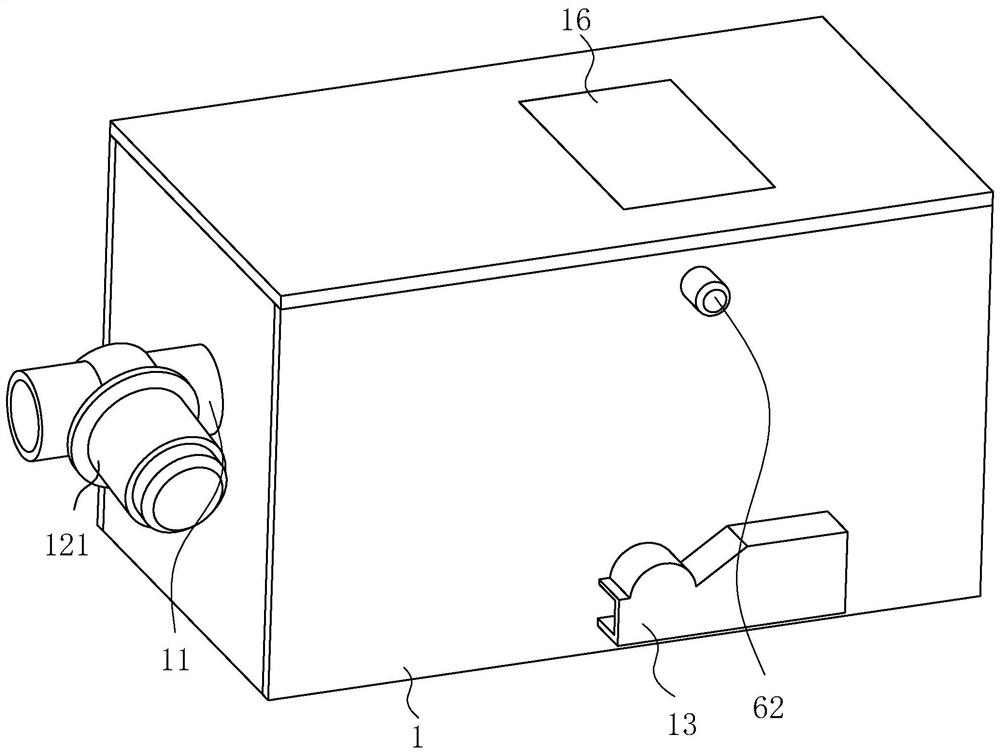

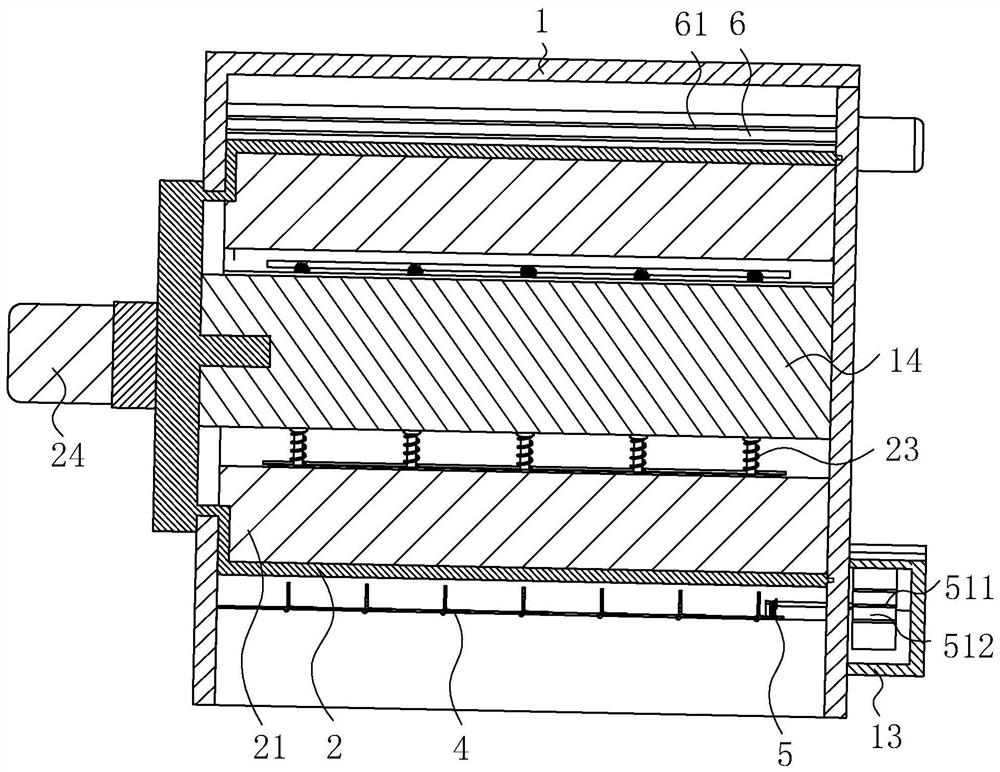

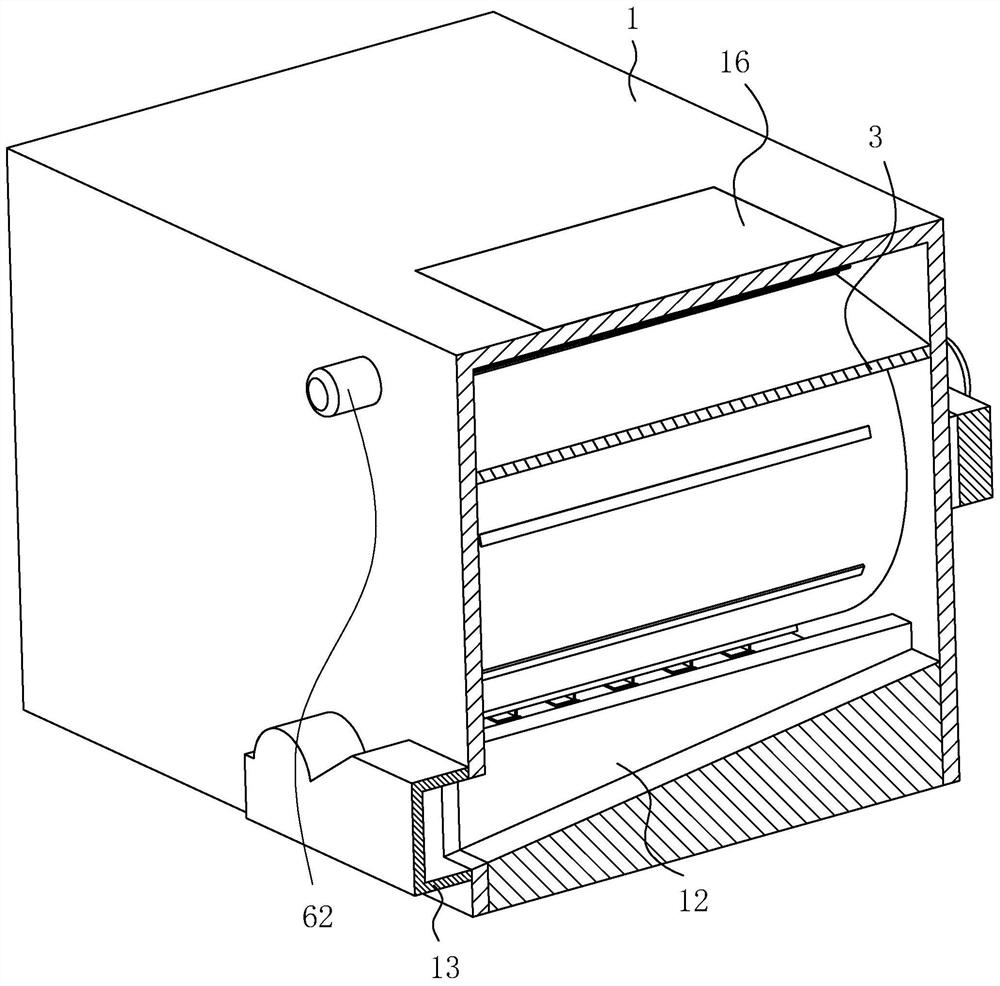

[0038] The embodiment of the present application discloses a magnetic coagulation high gradient magnetic separator. refer to figure 1 with figure 2, a magnetic coagulation high-gradient magnetic separator includes a casing 1, a magnetic cylinder 2 is rotatably connected to the casing 1, and a magnetic body 21 is connected to the inner wall of the magnetic cylinder 2, and the magnetic body 21 can be a magnet, a cylindrical magnetic drum, etc. magnetic substance, the magnetic cylinder 2 is connected with a driving motor 24 capable of driving itself to rotate, and the casing 1 is provided with a sludge inlet 11 and a sludge outlet 12 (refer to image 3 ), the sludge inlet 11 and the sludge outlet 12 are located on both sides of the magnetic cylinder 2, the tangential direction of the lower edge of the magnetic cylinder 2 along its rotation direction is opposite to the flow direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com