Preparation and extraction process of ganoderma lucidum spore powder zymolyte and product and application thereof

A technology of Ganoderma lucidum spore powder and spore powder enzyme is applied in the directions of medical preparations with non-active ingredients, medical preparations containing active ingredients, and drug combinations to achieve the effects of prolonging sleep time, improving sleep, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Step 1: Preparation of Ganoderma lucidum spore powder enzymatic hydrolyzate

[0067] Ganoderma lucidum spore powder 2000g, trypsin 4g, 50% ethanol-water solution (v / v) 6000mL, put in a 10L stainless steel bucket, and put it in a constant temperature water bath at 55°C, adjust the pH value to 6.0, and start the stirrer to stir the reaction solution , control the rotation speed of the stirrer to 300rpm, react for 4h, heat up to 90°C to inactivate the enzyme for 20min, take out the reaction liquid, filter to obtain the filtrate. The filtrate is concentrated and spray-dried to obtain the enzymatic hydrolyzate of ganoderma lucidum spore powder.

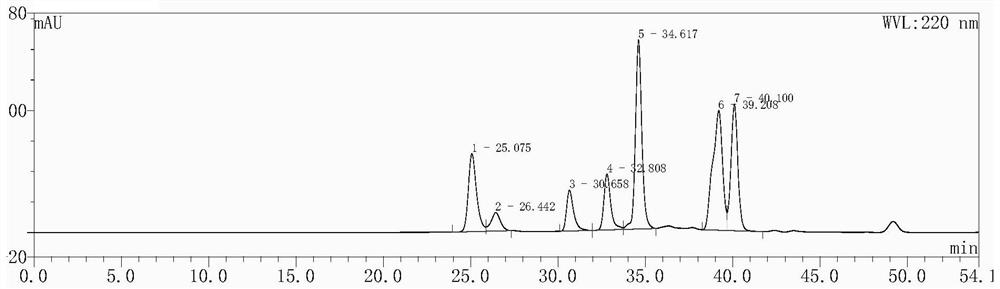

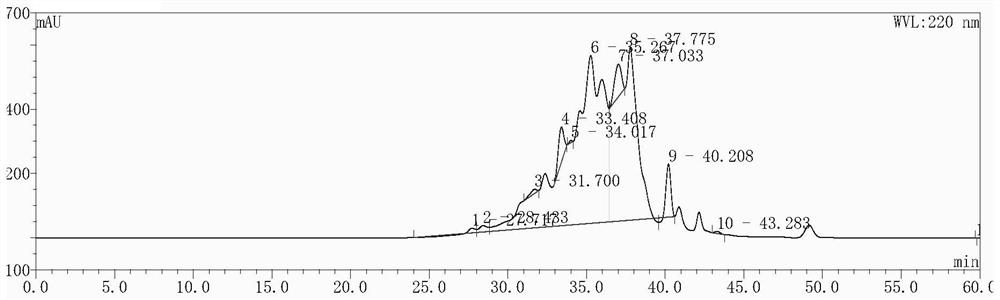

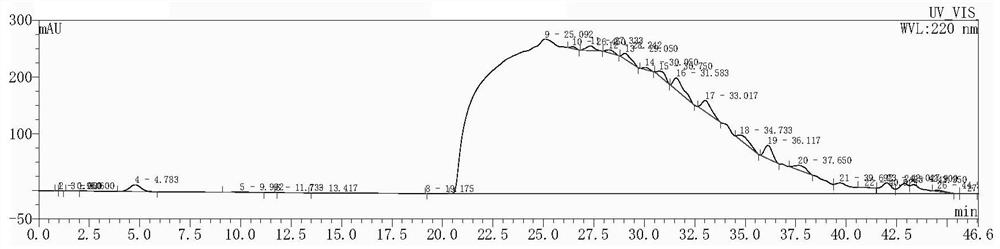

[0068] The molecular weight distribution of the peptides in the ganoderma lucidum spore powder enzymatic hydrolyzate prepared in this example was tested and analyzed by gel permeation chromatography, and the results were as follows figure 1 , figure 2 As shown in Table 1 below (results of molecular weight distribution of peptides...

Embodiment 2

[0152] Ganoderma lucidum spore powder 1500g, trypsin 3g, different volume concentration (0%, 40%, 50%, 60%, 100%) ethanol-water solution 6000mL, be placed in 10L stainless steel bucket, and be placed in 50 ℃ constant temperature water bath, adjust The pH value is 5.5, and the stirrer is started to stir the reaction solution. The stirrer speed is controlled to 300rpm, and the reaction is carried out for 4 hours. The temperature is raised to 90°C to inactivate the enzyme for 20 minutes. The filtrate is concentrated and spray-dried to obtain the finished product of ganoderma lucidum spore powder enzymatic hydrolyzate.

[0153]The main component analysis of different ganoderma spore powder enzymatic hydrolyzates prepared in this example, the results are shown in Table 16 below, as can be seen from the table, when 100% water is used as a solvent to carry out enzymatic treatment and active substance extraction of ganoderma spore powder, The crude polysaccharide content in the obtain...

Embodiment 3

[0158] Step 1: Preparation of Ganoderma lucidum spore powder enzymatic hydrolyzate

[0159] Ganoderma lucidum spore powder 1000g, trypsin 2g, 40% ethanol 3500mL, put in a 10L stainless steel bucket, and put it in a constant temperature water bath at 55°C, adjust the pH value to 6.0, and start the stirrer to stir the reaction solution, control the stirrer speed to 300rpm , reacted for 4 hours, raised the temperature to 90° C. to inactivate the enzyme for 20 minutes, took out the reaction solution, and filtered it to obtain a filtrate. The filtrate is concentrated and spray-dried to obtain the finished product of ganoderma lucidum spore powder enzymatic hydrolyzate.

[0160] Step 2: Preparation of Ganoderma lucidum spore powder enzymatic hydrolyzate compound preparation

[0161] A compound preparation of enzymatic hydrolyzate of ganoderma spore powder for improving sleep, especially able to improve sleep disturbance induced by pentobarbital sodium, which includes the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com