Process for producing receiver substrate for semiconductor-on-insulator structure for radiofrequency applications and process for producing such structure

A technology of semiconductors and insulators, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as breakdown voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The invention relates to a method of manufacturing a receiver substrate (30) of a semiconductor-on-insulator structure for radio frequency applications, comprising the steps of:

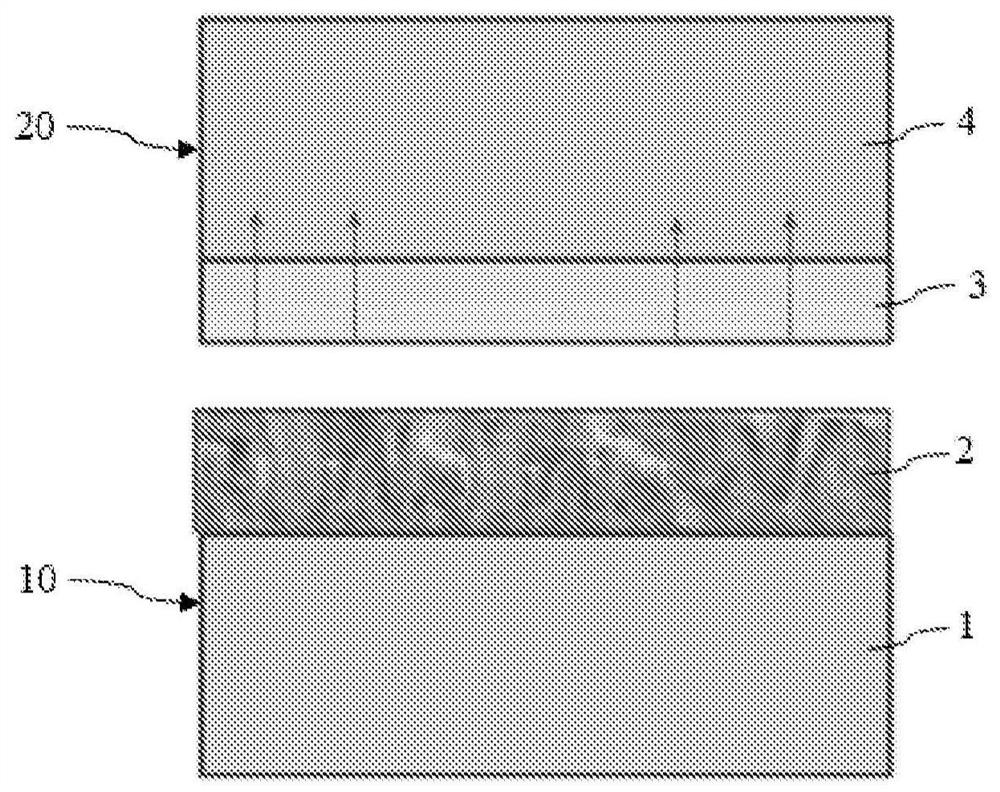

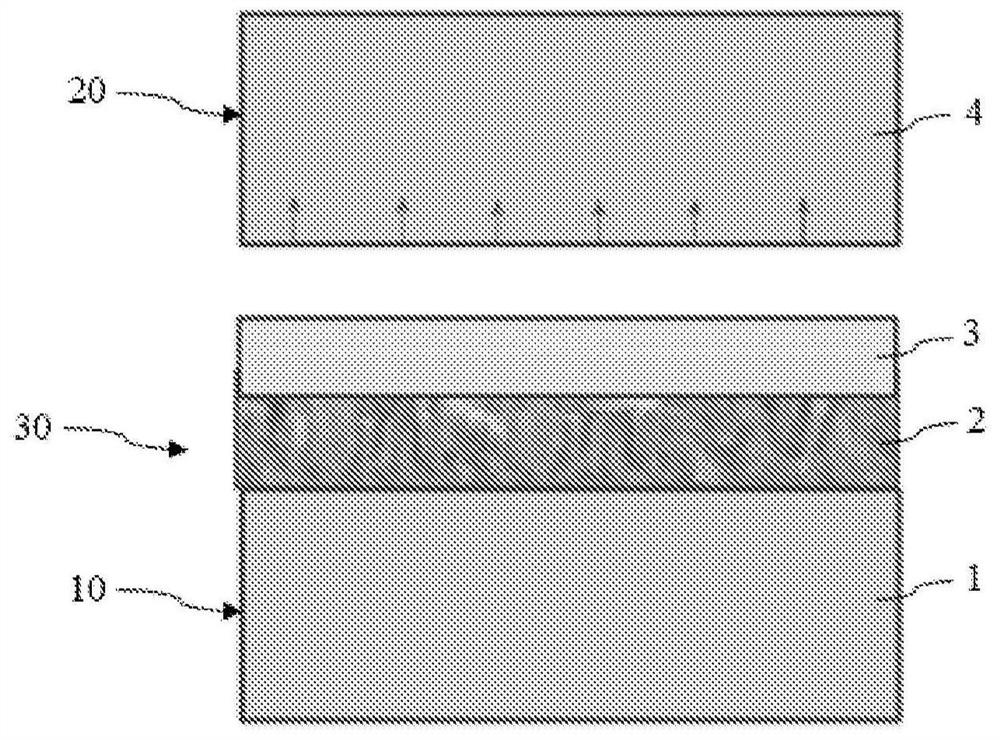

[0067] The method of the present invention is a reverse splicing method. refer to figure 2 , the method includes the step of providing a semiconductor substrate 10 comprising a base substrate 1 made of a single crystal material and a charge-trapping layer 2 made of polysilicon disposed on the base substrate, followed by a pair of charges The trapping layer 2 is oxidized to form an oxide layer 3 disposed on said charge trapping layer.

[0068] The charge-trapping layer 2 may be formed by epitaxy on the base substrate 1, or alternatively deposited thereon by chemical vapor deposition (CVD).

[0069] The charge-trapping layer 2 is at least partially oxidized at a temperature comprised between 750°C and 875°C.

[0070] Such a method makes it possible to form, by reverse bonding, a receiver sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com