Model and method for predicting yield of chitosan prepared from armadillidiam vulgare at different water bath temperatures

A technology of water bath temperature and prediction method, which is applied in the direction of instruments, biological systems, bioinformatics, etc., can solve the problems of resource waste, retention, and difficulty in industrial utilization, and achieve the effect of improving production efficiency and reducing preparatory work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A predictive model for the yield of chitosan prepared by chrysalis worms at different water bath temperatures. The corresponding products are demineralized extract, chitin, decolorized extract and chitosan;

[0033] The yield prediction model includes the prediction of extract yield after demineralization, the prediction of chitin yield, the prediction of extract yield after decolorization, the prediction of chitosan yield and the prediction of total yield, wherein,

[0034] Extraction yield P after demineralization 1 =0.0000243929T 1 2 -0.0053407857T 1 +0.6353100000,

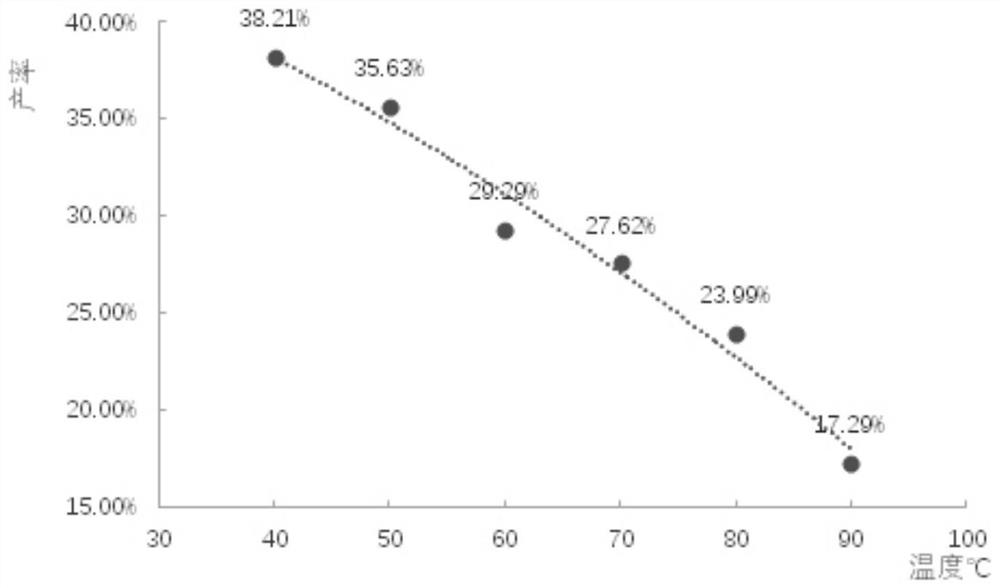

[0035] Chitin yield P 2 =-0.0000174286T 2 2 -0.0017682857T 2 +0.4803742857,

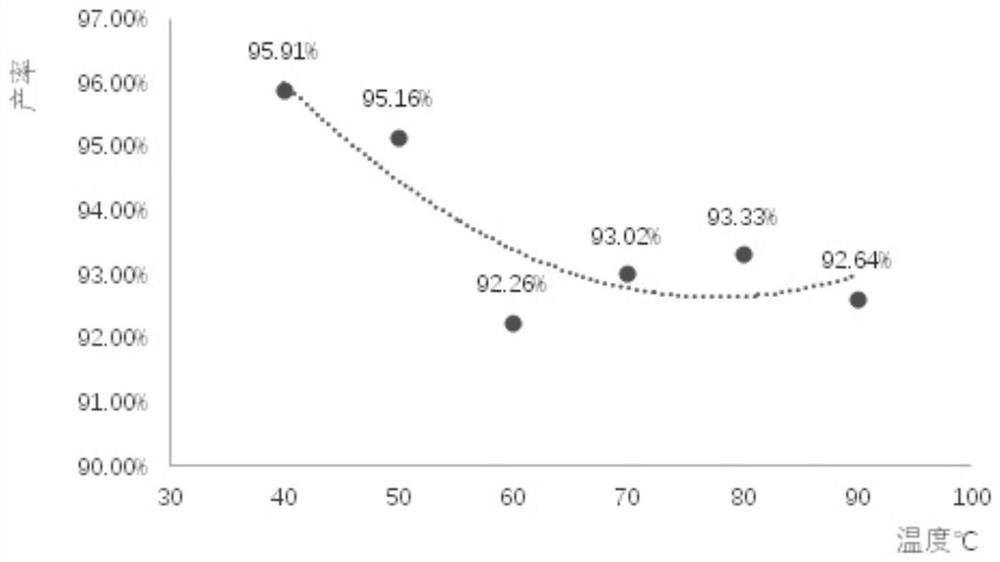

[0036] Extract yield P after decolorization 3=0.0000234643T 3 2 -0.0036526429T 3 +1.0686414286,

[0037] Chitosan yield P 4 =-0.0000555000T 4 2 +0.0047692857T 4 +0.6629285714,

[0038] Total yield P t =P 1 *P 2 *P 3 *P 4 ,

[0039] In the formula, T 1 Water bath temperature for demineralization of raw ...

Embodiment 2

[0040] Example 2 Construction of a predictive model for preparing chitosan yields by worms under different water bath temperatures

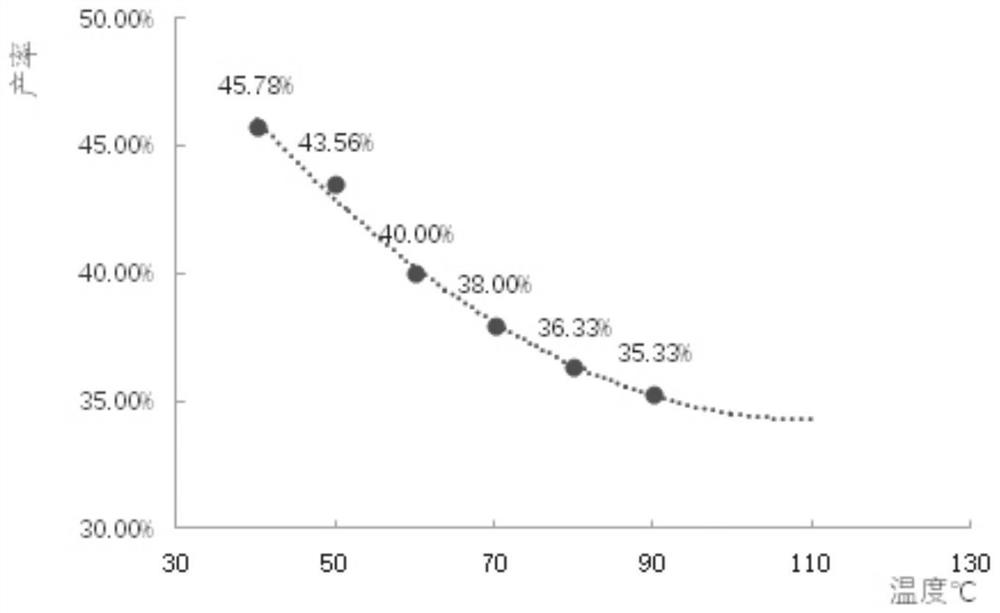

[0041] (1) Construction of predictive model for extract yield after demineralization

[0042] After cleaning, drying and pulverizing the worms, the worm powder was dispersed in 10% HCl solution at a solid-to-liquid ratio of 1:10, and heated in a water bath at different temperatures for 1.5 hours. Cool to room temperature and centrifuge at 1500r / min, wash the centrifugal precipitate until the pH value of the washing liquid is neutral, then dry the centrifugal precipitate at 60°C to obtain the demineralized extract, and weigh it;

[0043] Among them, a total of 6 temperature gradients were set for the water bath heating treatment, which were 40°C, 50°C, 60°C, 70°C, 80°C, and 90°C, and each temperature gradient was repeated three times.

[0044] According to the formula: extract yield after demineralization = extract mass after demineralization / mas...

Embodiment 3

[0058] Use the yield prediction model of Example 1 to predict the product yield and total yield of each stage of chitosan prepared by chrysalis under different water bath temperatures. and deacetylation treatment in four stages, and the corresponding products of the four stages are demineralized extract, chitin, decolorized extract and chitosan, among which,

[0059] The demineralization treatment is as follows: after washing, drying and crushing the worms, the worms powder is obtained, and the worms powder is dispersed in a 10% HCl solution at a solid-to-liquid ratio of 1:10, and placed at 40-100°C Heat treatment in water bath for 1.5h;

[0060] The specific treatment of organic matter removal is: disperse the demineralized extract in 6% NaOH solution at a solid-to-liquid ratio of 1:10, and heat it in a water bath at 40-100°C for 10 hours;

[0061] The decolorization treatment is as follows: disperse chitin in 10% H at a solid-to-liquid ratio of 1:10 2 o 2 In the solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com