A color-blind and color-deficient correction mirror and preparation method thereof

A technology for correcting glasses and color blindness, which is applied in the field of optical materials, can solve the problems that color blindness correction glasses cannot accurately filter colors, and the effect of color vision correction is limited, and achieve the effects of high safety, non-toxicity, low cost, and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

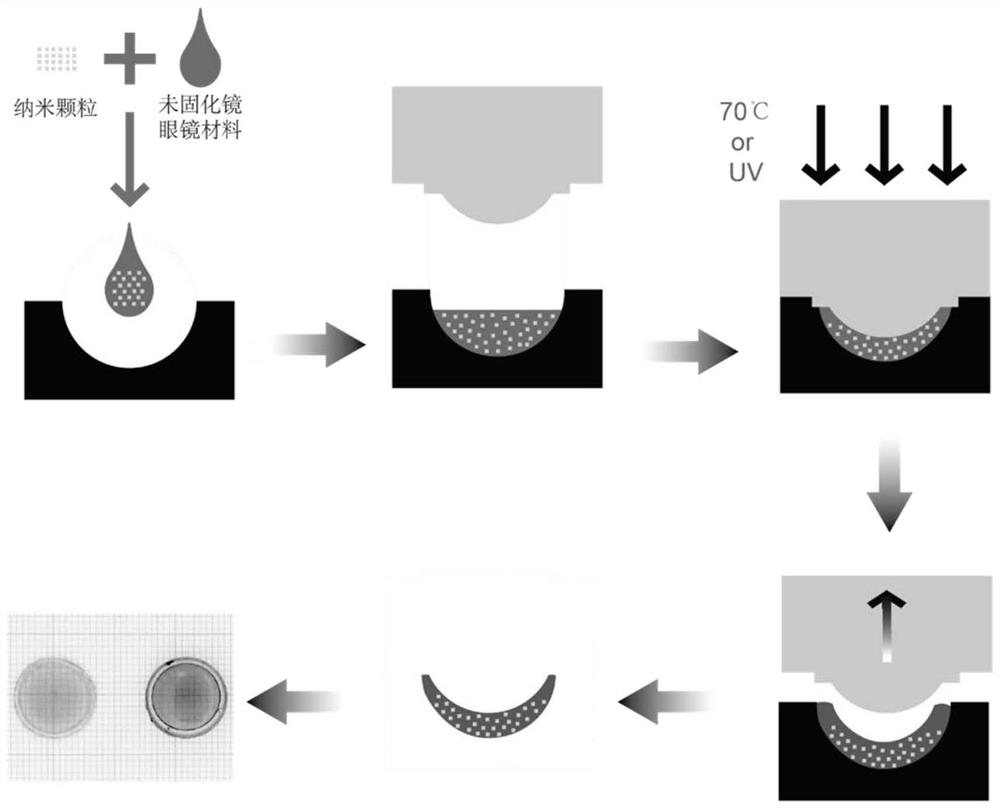

[0040] This embodiment provides a preparation method of color blindness and color weakness correction lens, see figure 1 , the steps are as follows:

[0041] (1) Prepare KH590 solution: dilute 20.3ul KH590 with alcohol to 10ml for later use; prepare a total of 2ml of TEOS ethanol solution with a volume fraction of 20% for later use.

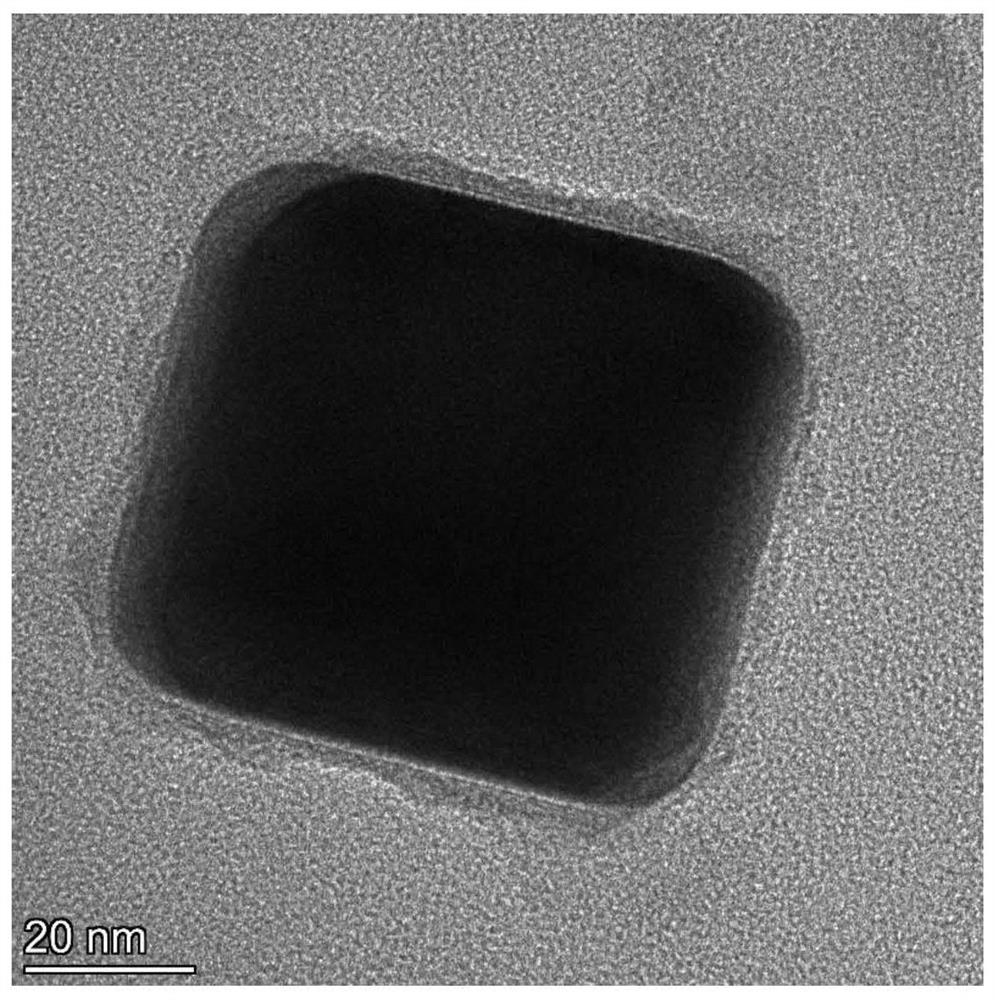

[0042](2) Pour 40ml 0.5mmol / L size of 20nm gold nano-nucleus dispersion liquid into the container, the dispersion liquid is the aqueous solution of CTAB, after the dispersion liquid is ultrasonically dispersed for ten minutes to make it fully dispersed, add 800ul 0.01 mol / L KH590 solution was stirred at room temperature with a magnetic stirrer at 3000 rpm for five hours to fully react to form Au-S bonds on the surface of the Au nano-core. Then add 200ul of TEOS ethanol solution with a volume fraction of 20% to the container, then add an appropriate amount of ammonia water to adjust the pH of the solution to between 10 and 11, and continue stirri...

Embodiment 2-5

[0045] This embodiment 2-5 provides a preparation method of a color blindness and color weakness correction lens, the steps of which are the same as those of embodiment 1, please refer to Table 1 for the differences.

[0046] The raw material parameter of table 1 nanoparticle

[0047] Gold nanonuclei size Example 2 35nm Example 3 50nm Example 4 60nm Example 5 70nm

Embodiment 6

[0049] This embodiment provides a method for preparing a color blindness correction lens, which is the same as step (1) and step (2) in Example 1, except that step (3) is different, as follows:

[0050] Step (3) Add 1.41g HEMA, 0.3g NVP, 0.03g EGDMA, 0.02g AIBN, 6g ethylene glycol, 2.16g water in another container, stir at room temperature for half an hour to fully mix, and get HEMA-NVP water Gel precursor. Then add the above nanoparticles, stir to fully mix the nanoparticles and the solution, and ultrasonically disperse the nanoparticles in the HEMA-NVP hydrogel precursor for 15 minutes to obtain a mixed solution, then pour the mixed solution into a mold, and heat it at 70°C The HEMA-NVP hydrogel is cured by heating for five hours or under the catalysis of ultraviolet light, and the cured hydrogel is taken out from the mold to obtain a color blindness and color weakness correction lens.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com