Method and device for measuring alkali metal surface tension coefficients at different temperatures

A surface tension coefficient, alkali metal technology, applied in the direction of surface tension analysis, etc., can solve problems that are difficult to measure the surface tension coefficient of alkali metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with specific embodiments.

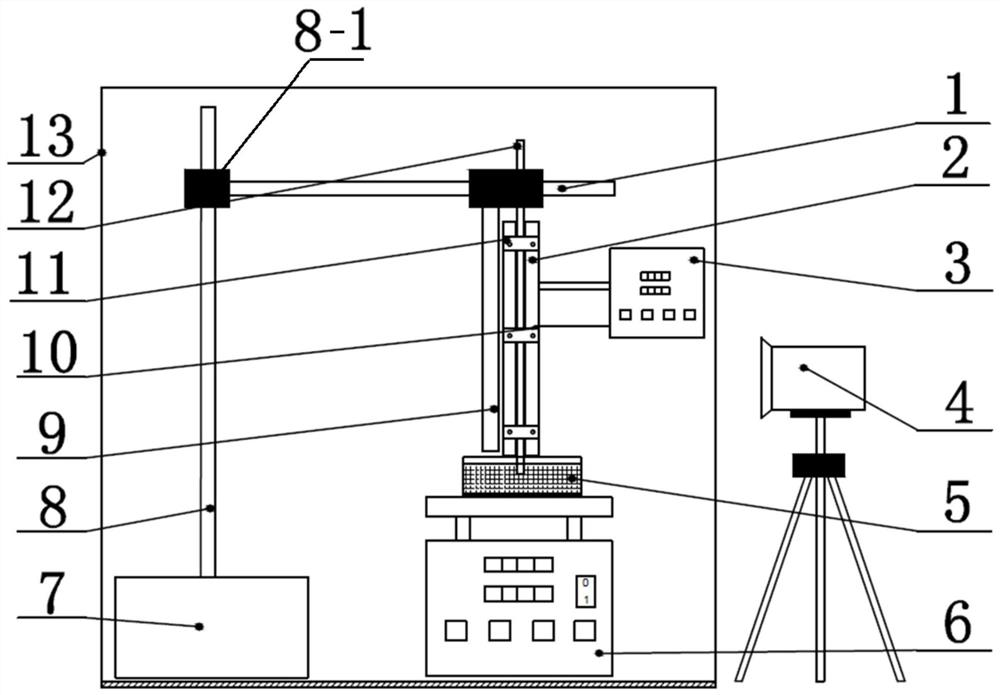

[0067] The device for measuring the surface tension coefficient of alkali metals under different temperatures of the present invention comprises the following components:

[0068] An electric heating table 6 for melting alkali metals;

[0069] Container 5 for containing molten alkali metal;

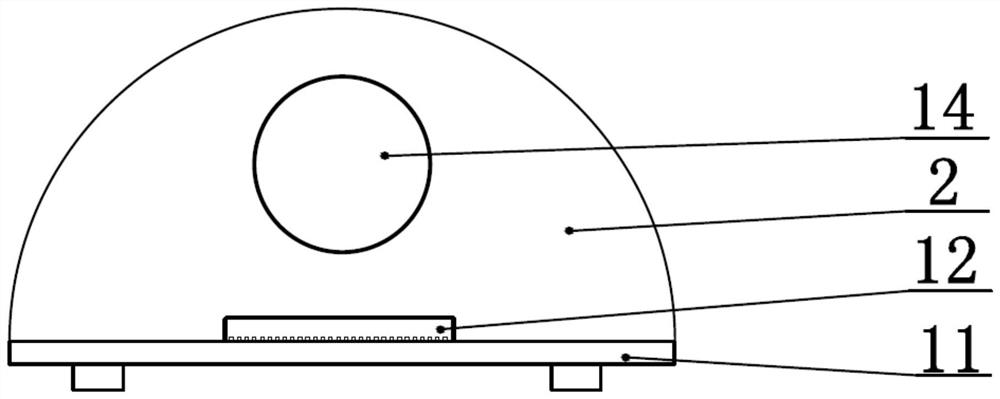

[0070] A liquid-absorbing core 12 for measuring the surface tension coefficient of the alkali metal melt;

[0071] A heater for heating the wick 12;

[0072] The lifting mechanism for clamping and adjusting the height of the liquid-absorbing core 12 is used to change the insertion depth of the lower end of the liquid-absorbing core 12 into the liquid surface of the alkali metal melt.

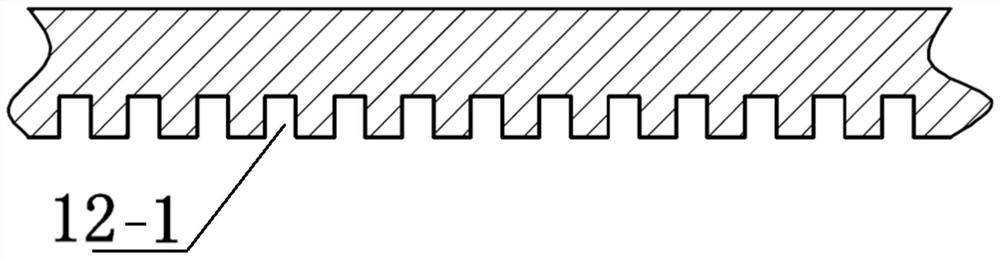

[0073] The liquid-absorbing core 12 is a bar-shaped metal plate with a plurality of axially distributed rectangular grooves 12-1 opened on one side surface;

[0074] The heater includes a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com